A combined underwater production support buoy and its integral installation and recovery method

A combined and integrated technology, applied in anchoring arrangements, floating buildings, transportation and packaging, etc., can solve the problem of difficult to facilitate top tension, increased rigid riser top tension, and rigid riser body stress changes. and other problems to achieve the effect of improving strength and fatigue resistance, reducing force and motion range, and improving strength and fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

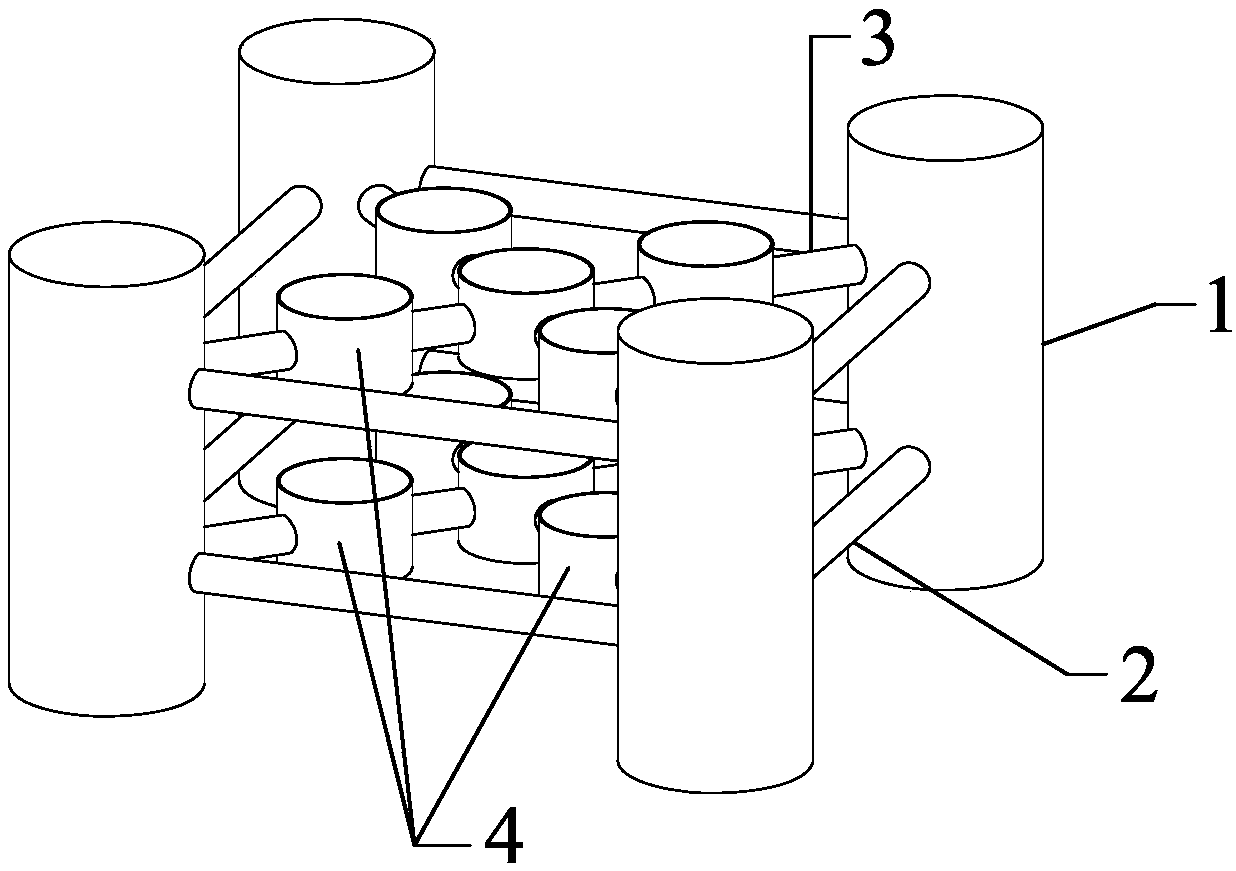

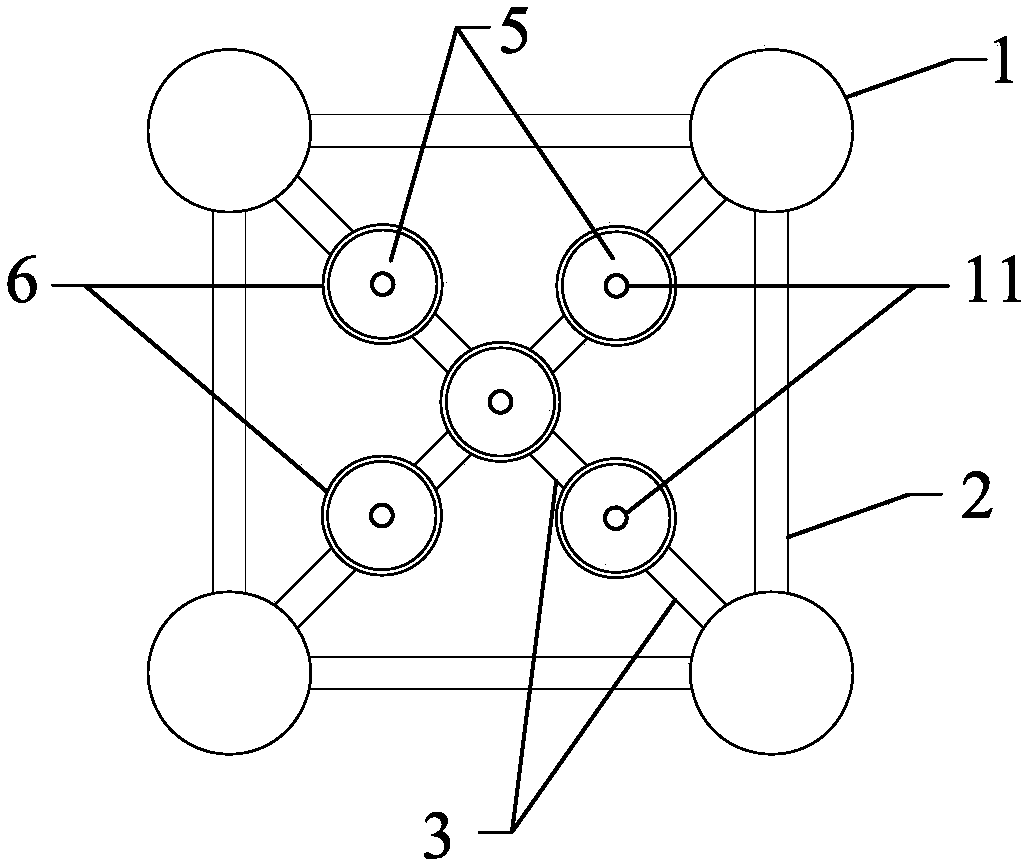

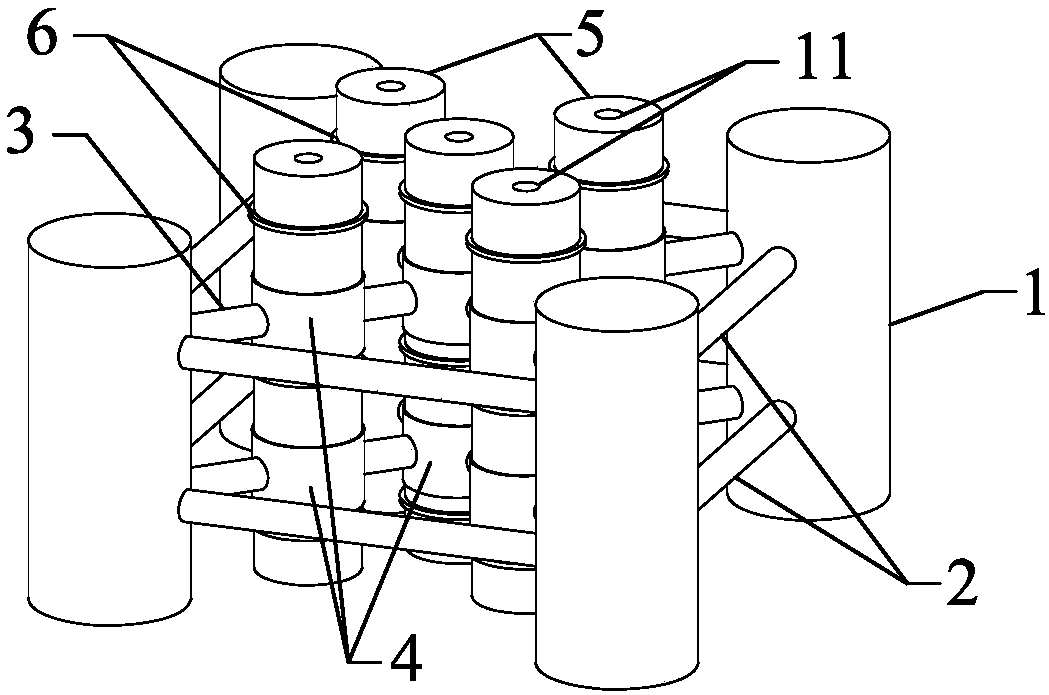

[0068] The present invention will be further described below in conjunction with the accompanying drawings. this invention Figure 1-4 The subsea production support buoy of an ultra-deepwater offshore oil and gas engineering development system with five rigid risers is shown as an example. A combined underwater production support buoy, comprising an outer buoy 1, an inner buoy 5, a peripheral cross brace 2, an inner cross brace 3, a guide ring plate 4 and a limit plate 6;

[0069] There are four outer buoys 1, all of which are cylindrical, and the four outer buoys 1 are connected by peripheral cross braces 2 to form an outer buoy assembly; the outer buoy assembly is a rectangular frame, and the four outer buoys 1 is vertically installed on the four corners of the horizontal plane of the rectangular frame, and the axes of the four outer buoys 1 are parallel to each other; the four outer buoys 1 are respectively moored on the pile foundation 9 of the seabed 13 by four mooring c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com