Treatment method of chloroacetic acid by-product crystallization mother liquid

A technology of crystallization mother liquor and treatment method, which is applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of difficult and high treatment cost of chloroacetic acid mother liquor, and achieve the effect of reducing equipment costs and energy consumption costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

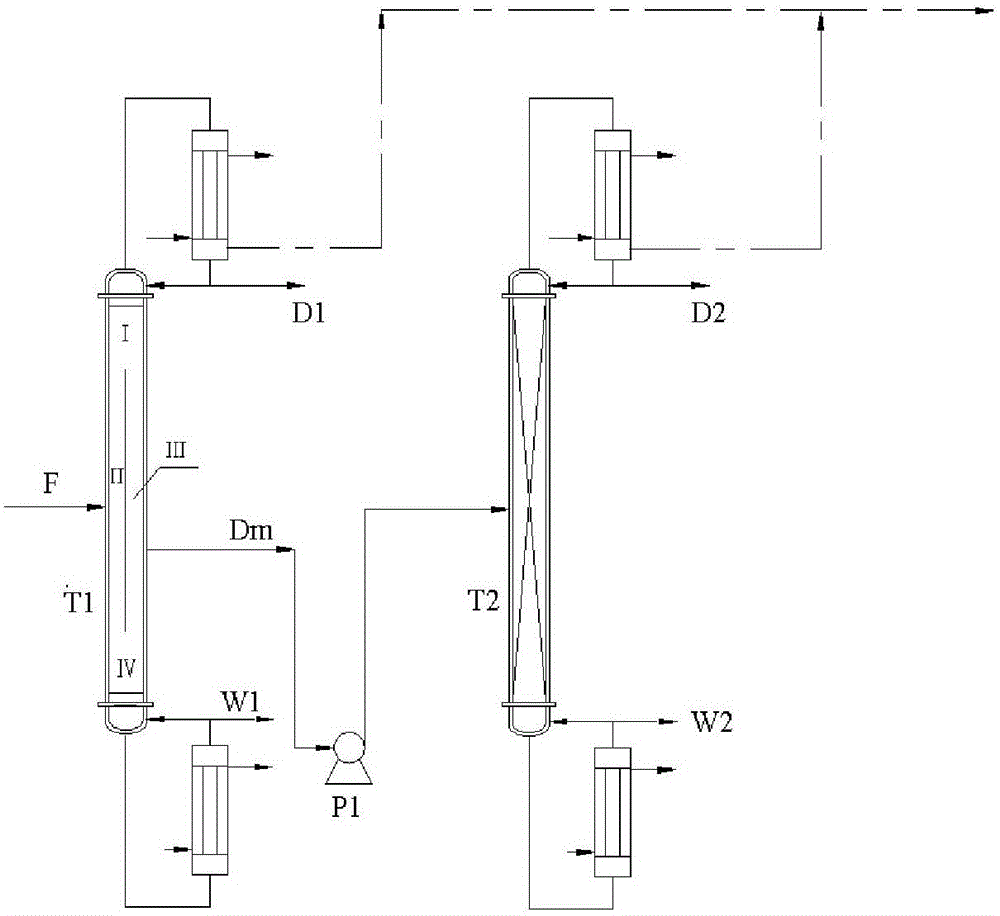

Image

Examples

Embodiment 1

[0037] In Example 1, the partitioned rectification tower T1 is 8 meters high, the T2 tower is 22 meters high, and the T1 tower is filled with corrugated plates. The chloroacetic acid crystallization mother liquor raw material is added to the middle part of the partitioned rectification tower T1, and the feed rate is 500kg / h. After the raw material is heated and vaporized in the tower reactor, the steam enters the rectification tower upwards, and the liquid that refluxes with the top condenser in the tower Gas-liquid mass transfer is carried out on the packing surface, the top pressure of T1 tower is 1kPa, water, acetic acid and other low-boiling impurities D1 are extracted from the top of T1 tower, and the extraction rate is 80kg / h, and the material is discharged from the side line at 3m from the bottom of T1 tower The mixture Dm of monochloroacetic acid and dichloroacetic acid is extracted at one point, and the extraction rate is 370kg / h, and the high boiling point impurity W1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com