Rotational moulding foaming polyethylene composite and polyethylene foaming product

A technology of foaming polyethylene and polyethylene foaming, applied in the direction of coating, etc., can solve the problems of resin strength and temperature resistance decline, cell coarsening, etc., and achieve excellent processing performance, small cell structure, and processing performance easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

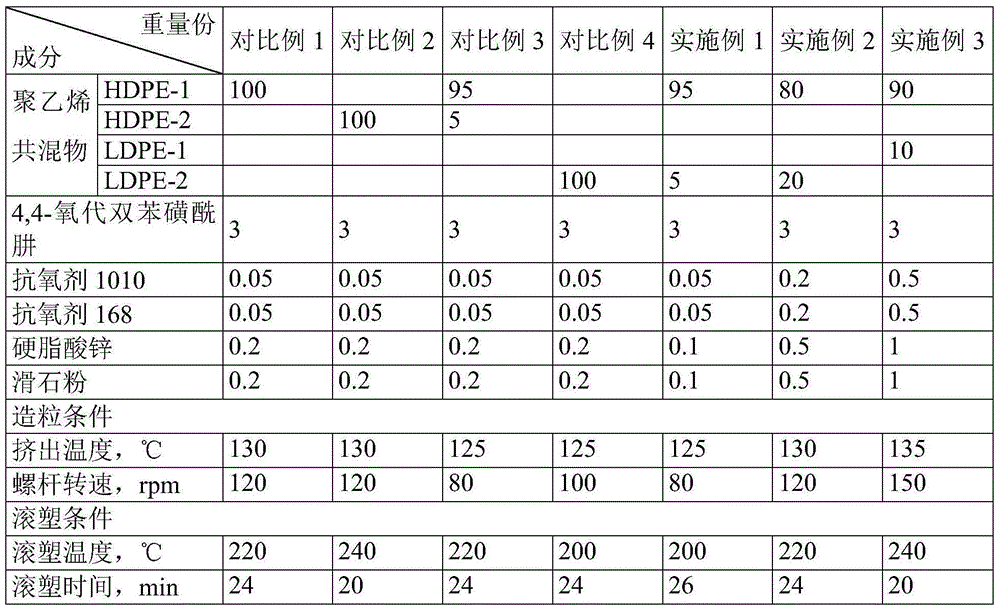

[0046] This example is used to illustrate the foamed polyethylene composition for rotomolding and the polyethylene foamed product provided by the present invention.

[0047] (1) Mixing: According to the material composition listed in Table 1, the density, crystallization enthalpy and melt index of the polyethylene blend were measured, and the results are shown in Table 2. Add various materials into the mixer and stir until they are evenly mixed;

[0048] (2) Pelletization: The mixture was added into a twin-screw extruder (Model RheoDrive16 from Thermo Fisher Company) for extrusion and granulation. The extrusion temperature and screw speed are shown in Table 1. Drying the granulated product at 60° C. for 3 hours to obtain pellets, which is a foamed polyethylene composition for rotational molding;

[0049] (3) Grinding and sieving: After the pellets are ground, sieve out powders with a particle size smaller than 35 meshes, which are used as rotomolding foaming raw materials;

...

Embodiment 2-3

[0055] This example is used to illustrate the foamed polyethylene composition for rotomolding and the polyethylene foamed product provided by the present invention.

[0056] According to the method of Example 1, the density, crystallization enthalpy and melt index of the polyethylene blend listed in Table 1 were measured, see Table 2.

[0057] According to the material composition and conditions listed in Table 1, a foamed polyethylene composition for rotational molding and a polyethylene foamed product were obtained.

[0058] The pressure density of the obtained polyethylene foamed product was measured, the expansion ratio was calculated, and the inner surface of the product was observed. The results are shown in Table 2.

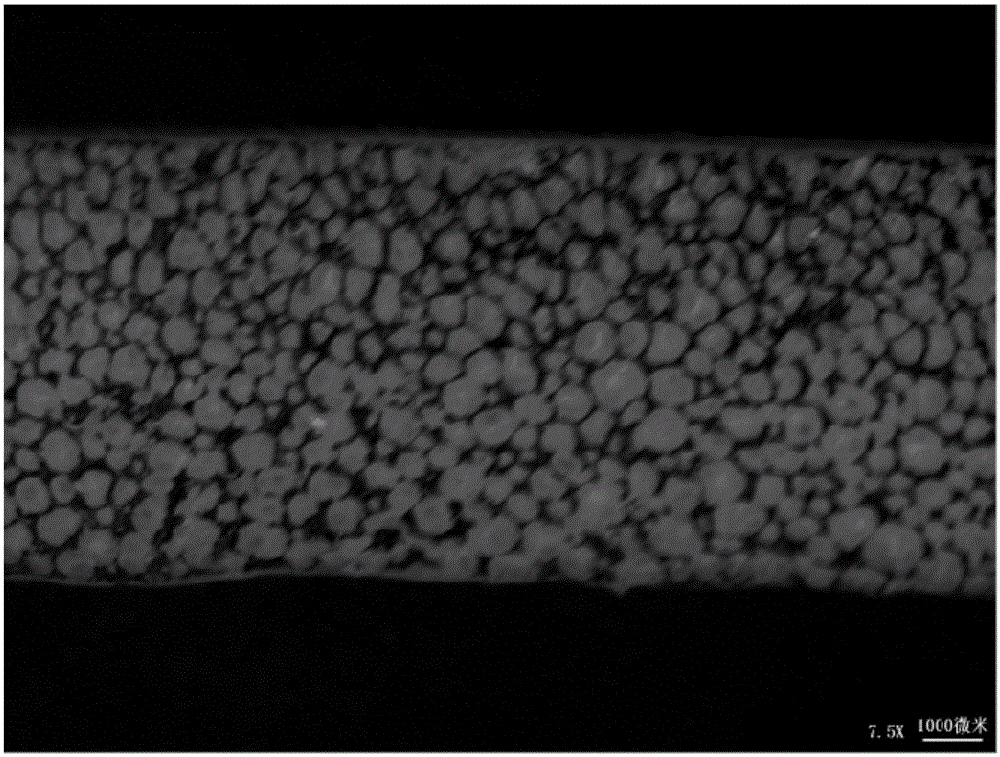

[0059] The obtained polyethylene foam product was cut open and the cell section and cell quality were observed with a microscope, and the average cell diameter and cell diameter distribution were measured and calculated. The results are shown in Table 2. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com