Method for producing starch by Monoraphidium

A single needle algae and starch technology, applied in the fields of biotechnology and bioenergy, can solve the problems of no discovery, single product, narrow application range, etc., and achieve the effects of improving starch yield, high starch content, and high starch content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

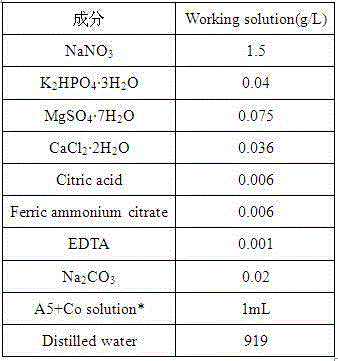

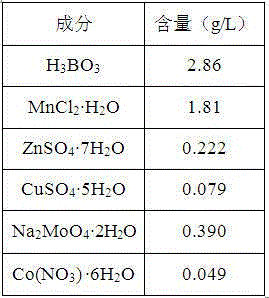

[0029] (1) Pick the monospora on the plate ( Monoraphidium sp. ) SS-06 was inserted into BG11 medium, at a temperature of 30°C, with an aeration of 0.25vvm, CO 2 The content is 2v%, the stirring speed is 100rpm, the pH is 7.0, the light intensity is 7000lux, and the light-to-dark ratio is 14:10. The microalgae seed liquid is obtained by culturing to the logarithmic growth phase.

[0030] (2) Insert the microalgae seed solution into the BG11 medium rich in N element according to the inoculation amount of 5v%. The enrichment of N element means adding NaNO at 3.0g / L to the BG11 medium 3 , cultivate until the logarithmic growth phase stops, and discharge the supernatant after standing to settle to obtain algae cells. The culture conditions are the same as step (1).

[0031] (3) Insert the algae cells obtained in step (2) into the microalgae medium containing low N elements. The microalgae medium containing low N elements is to add 0.05 g / L NaNO to the BG11 medium 3 , and add ...

Embodiment 2

[0034] (1) Pick the monospora on the plate ( Monoraphidium sp. ) SS-06 was inserted into BG11 medium, at a temperature of 25°C, an aeration rate of 0.25vvm, CO 2 The content is 1v%, the stirring speed is 100rpm, the pH is 6.0, the light intensity is 5000lux, and the light-to-dark ratio is 14:10. The microalgae seed liquid is obtained by culturing to the logarithmic growth phase.

[0035] (2) Insert the microalgae seed solution into the BG11 medium rich in N element according to the inoculation amount of 5v%. The enrichment of N element means adding NH at 2.0g / L to the BG11 medium 4 NO 3 , cultivate until the logarithmic growth phase stops, and discharge the supernatant after standing to settle to obtain algae cells. The culture conditions are the same as step (1).

[0036] (3) Insert the algae cells obtained in step (2) into the microalgae medium containing low N elements. The microalgae medium containing low N elements refers to adding 0.1g / L NH to the BG11 medium 4 NO ...

Embodiment 3

[0039] (1) Pick the monospora on the plate ( Monoraphidium sp. ) SS-06 was inserted into BG11 medium, at a temperature of 30°C, with an aeration of 0.25vvm, CO 2 The content is 3v%, the stirring speed is 100rpm, the pH is 8.0, the light intensity is 8000lux, and the light-to-dark ratio is 14:10. The microalgae seed liquid is obtained from the cultivation until the logarithmic growth phase.

[0040] (2) Insert the microalgae seed liquid into the BG11 medium rich in N element according to the inoculation amount of 5v%. The enrichment of N element means adding NH at 2.5g / L to the BG11 medium 4 Cl, cultivate until the logarithmic growth phase stops, and discharge the supernatant after standing to settle to obtain algae cells. The culture conditions are the same as step (1).

[0041] (3) Insert the algae cells obtained in step (2) into the microalgae medium containing low N elements. The microalgae medium containing low N elements refers to adding 0.05g / L NH to the BG11 medium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com