Pipe connecting structure and method and air conditioning unit pipe assembly

A technology for connecting structures and air-conditioning units, which is applied in the direction of non-removable pipe connections, pipes/pipe joints/pipes, mechanical equipment, etc. Reliability and durability, effect of enhanced weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

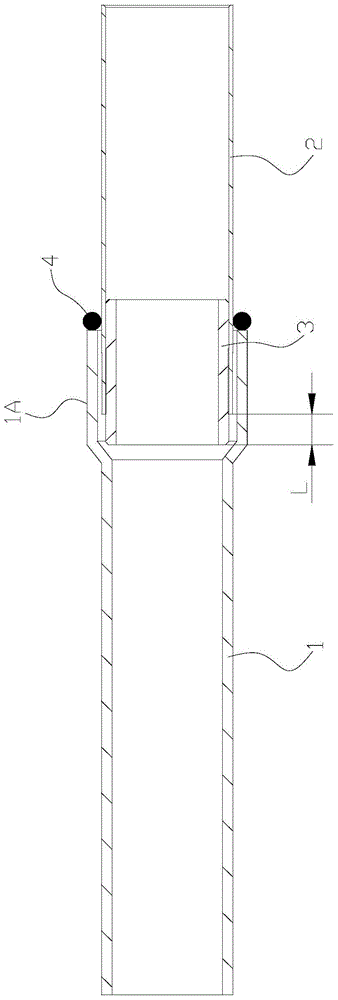

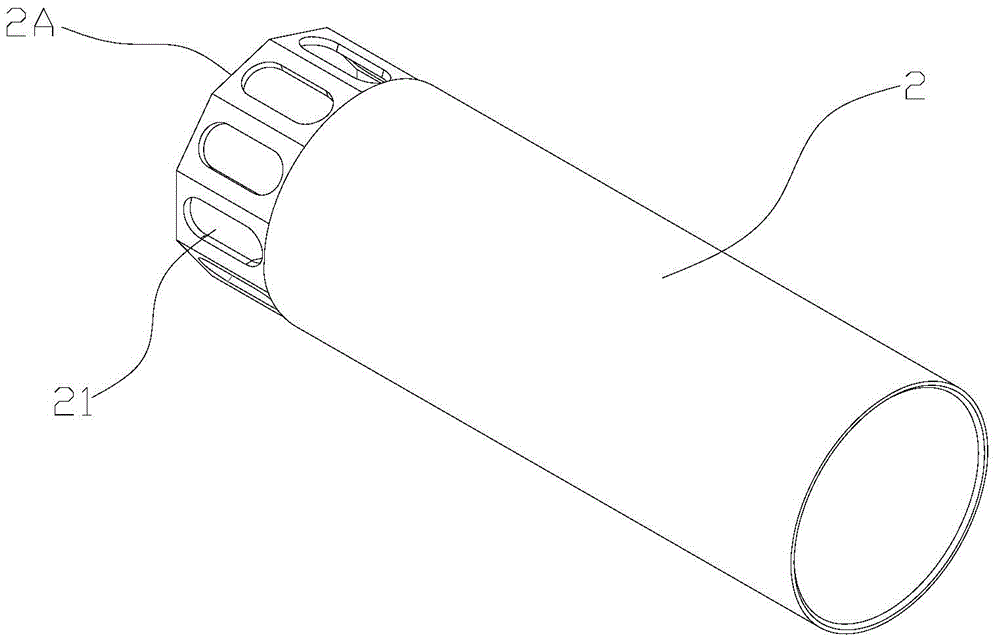

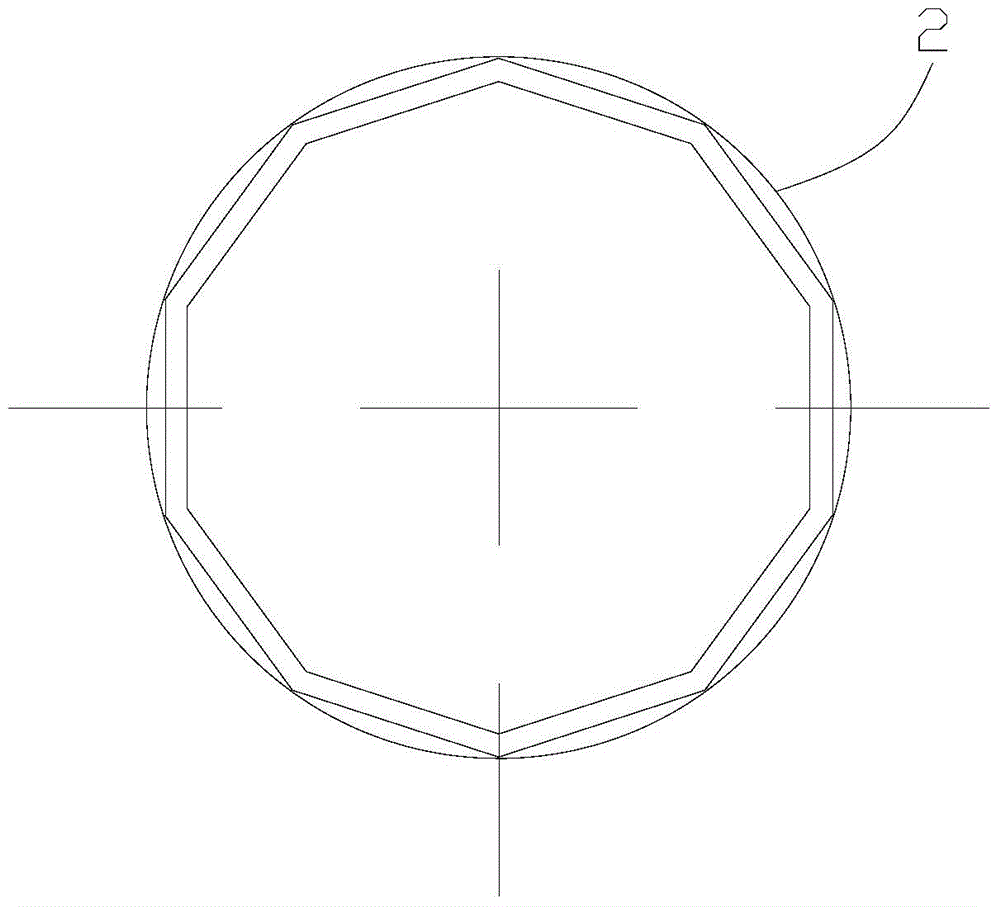

[0037] The core of the present invention is to provide a pipe connection structure, which is applied to the welding and fixing of two pipe fittings of different materials, which can improve the welding strength of the joint parts of the two pipe fittings and ensure the reliability and durability of the connection of the two pipe fittings. Another core of the present invention is to provide a pipeline connection method and a pipeline assembly of an air-conditioning unit including the above-mentioned pipeline connection structure.

[0038] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0039] It should be noted here that the connecting ends of the first pipe and the second pipe referred to herein refer to the interconnected ends of the two pipes.

[0040] For ease of understanding and br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com