System and method for rapidly measuring characteristic parameter of hub of wind power generation device

A technology of characteristic parameters and measurement system, applied in measurement devices, optical devices, instruments, etc., can solve the problem of not being separated from manpower, etc., and achieve the effects of high measurement efficiency, increased characteristic information, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

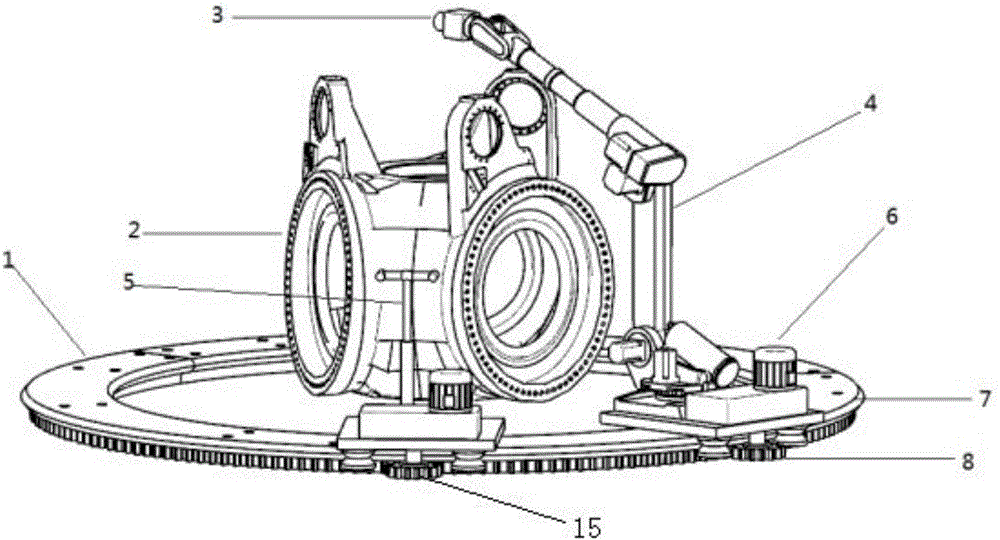

[0050] see figure 1 , the present invention provides a system and method for quickly measuring the characteristic parameters of the hub of wind power equipment, the system includes a circular track 1 and a mechanical support part arranged on the circular track 1, a projection light source 16, an optical measuring head 3 and an electrical control part ; The circular track 1 is laid around the wheel hub 2, and the circumference of the circular track 1 is provided with teeth; Upright; the mechanical support part includes a bracket 5 and a multi-degree-of-freedom mechanical arm 4 for supporting the projection light source 16; the multi-degree-of-freedom mechanical arm 4 is fixed on the first base 7, and the first base 7 is slidably connected with the ring track 1, and the first base 7 is provided with a first transmission gear 8 engaging the teeth on the ring track 1, and the first transmission gear 8 is connected with the first driving motor on the first base 7 6-axis connection...

Embodiment 2

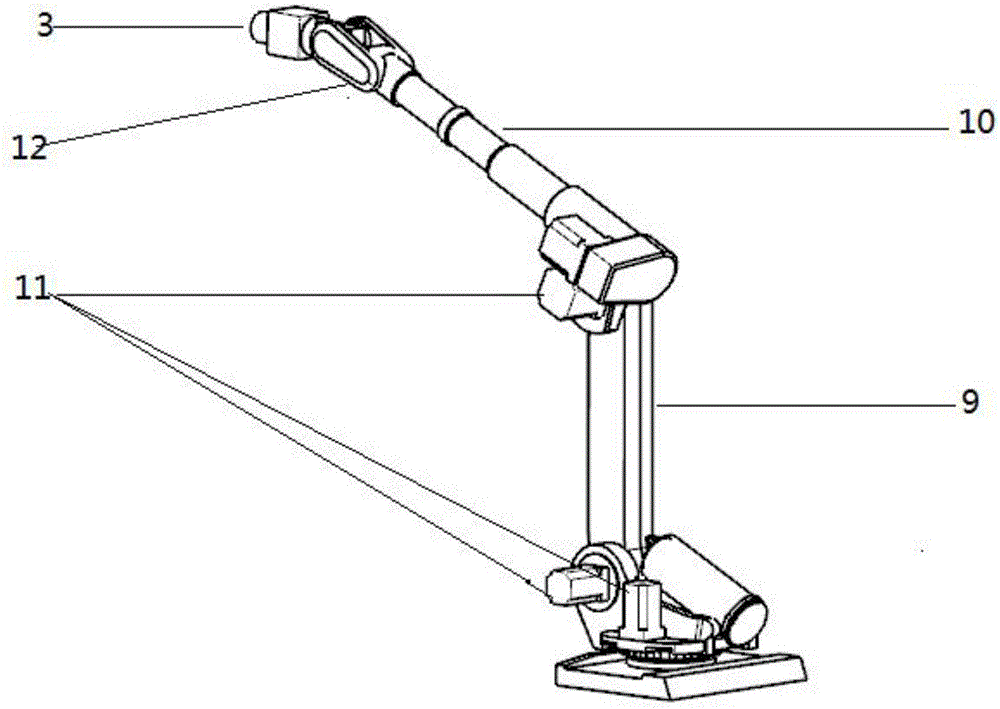

[0052] On the basis of embodiment 1, see figure 2 , the multi-degree-of-freedom mechanical arm 4 includes a large arm 9, a small arm 10 and a mechanical arm base, and the large arm 9, small arm 10, the mechanical arm base and the optical measuring head 3 parts all have at least one degree of freedom; wherein the large The arm 9 and the base of the mechanical arm, the large arm 9 and the small arm 10, the small arm 10 and the optical measuring head 3 are connected in rotation through rotating pairs, and each rotating pair is driven by a motor; the connection between the large arm 9 and the small arm 10 An elbow joint 11 is connected between the big arm 9 and the base of the mechanical arm. The optical measuring head 3 is connected to the small arm 10 through the measuring head clamping device 12 ; the base of the mechanical arm is fixed on the first base 7 . The projection light source 16 uses grating fringe projection to encode and dephase the grating fringes. The whole str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com