Surface waviness and roughness online measuring instrument

A surface waviness and roughness technology, applied in the field of measuring instruments, can solve the problems of low measurement efficiency, subjective factors, and small range, and achieve the effects of high-precision online measurement, efficient online detection, and fast moving speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

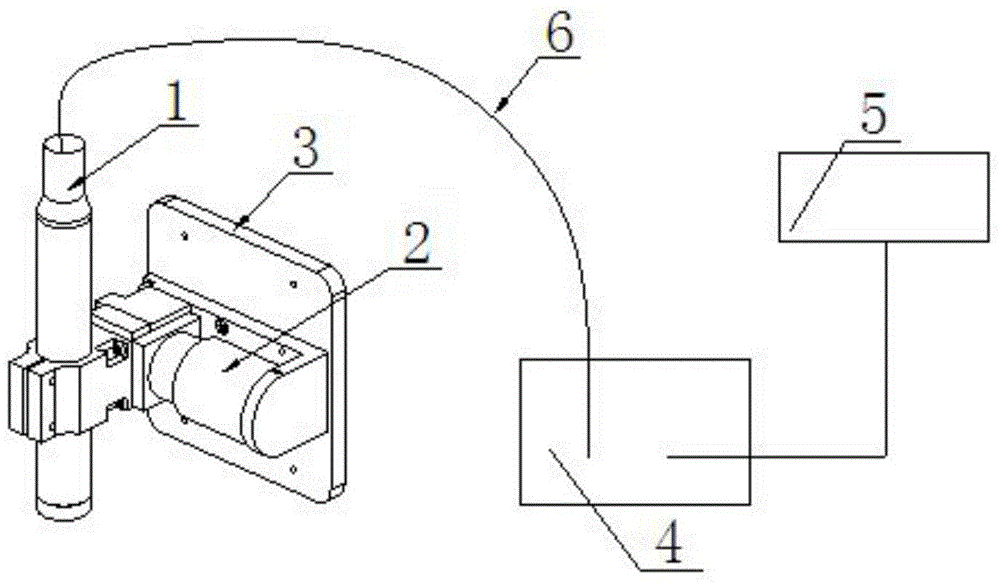

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0041] At first relevant technical terms in the present invention are explained:

[0042]Surface waviness: Surface waviness is the geometric unevenness of the surface whose spacing is larger than the surface roughness but smaller than the surface geometric shape error, which belongs to the geometric error between micro and macro. It is a periodic ups and downs formed on the surface of the part mainly due to the vibration of the machine tool-workpiece-grinding wheel system during the grinding process.

[0043] Surface roughness: surface roughness refers to the unevenness of the small spacing and small peaks and valleys of the processed surface. The distance (wave distance) between the two peaks or two troughs is very small (below 1mm), which belongs to the microscopic geometric shape error. The smaller the surface roughness, the smoother the surface. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com