Trench type processing method and system

A processing method and processing system technology, applied in the field of numerical control, can solve the problems of low programming efficiency and long programming time, and achieve the effect of high degree of automation, high versatility, and reducing the probability of manual programming errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment discloses a groove processing method applied to a numerical control machine tool, which is specially used for processing typical groove shapes. Among them, the so-called typical groove types include standard typical groove types such as double T-shaped grooves and single T-shaped grooves. The processing method of the groove type of this embodiment is embedded with the parameter verification of the cutting knife (straight groove cutting knife and curved groove cutting knife) and the radius verification of the circular arc radius of the round head knife, by checking the position of the edge of the knife, the width of the cutting knife , The arc radius of the tool nose is used to judge whether the input machine tool tool compensation parameters are correct, so as to avoid NCR (Non-conformance report) caused by human errors.

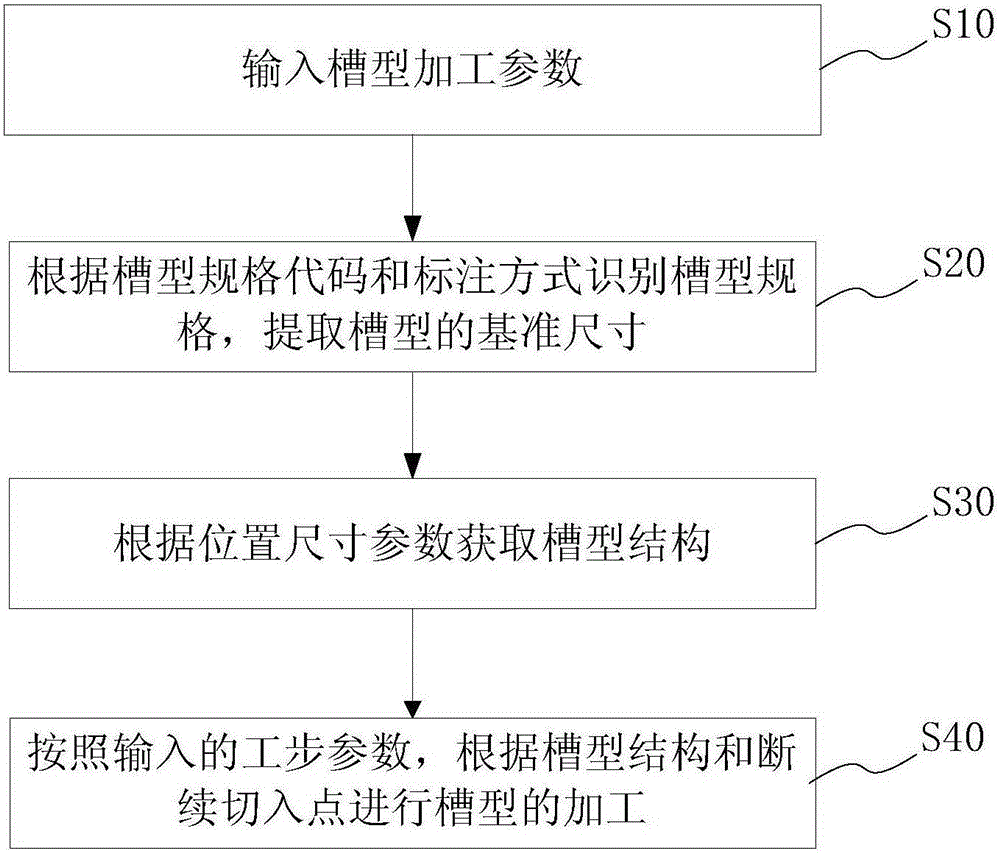

[0035] Such as figure 1 As shown, the processing method of the groove type of the present embodiment comprises:

[0036] Step S10, ...

Embodiment 2

[0062] This embodiment discloses a processing system for grooves applied to CNC machine tools, such as Figure 6 shown, including:

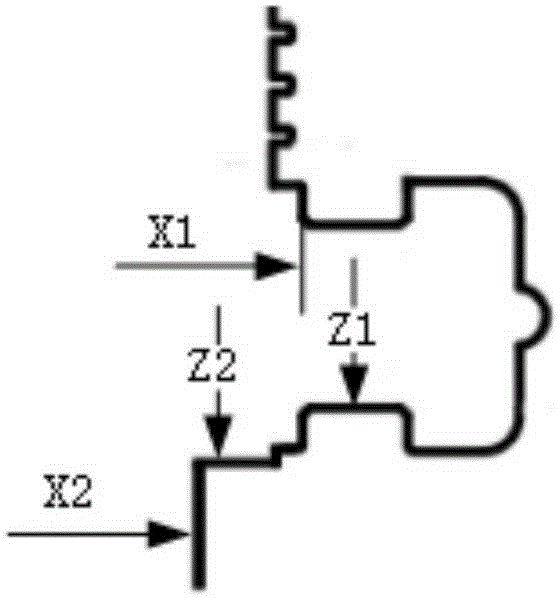

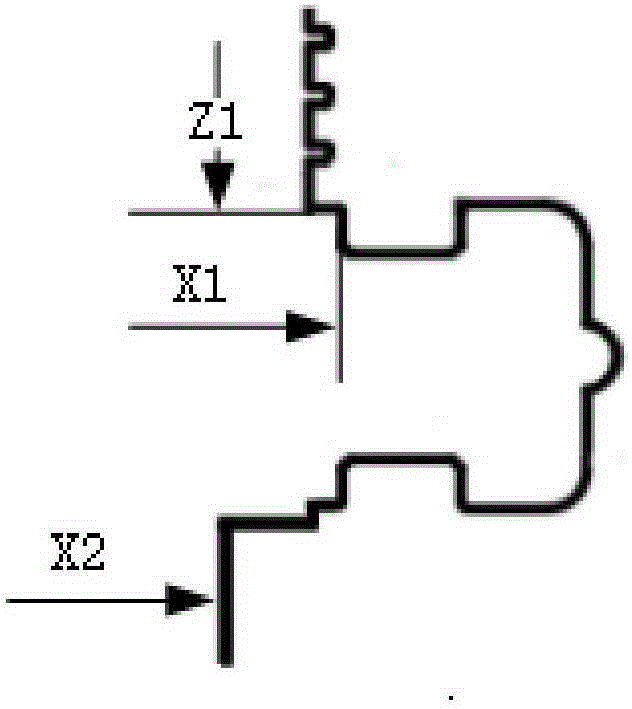

[0063] The input module 710 is used to input groove processing parameters; wherein, the groove processing parameters include groove specification codes, labeling methods, process step information, position dimension parameters and intermittent entry points; position dimension parameters include reference inner circle dimensions, groove Dimensions of the inner circle of the lower plane, axial positioning dimensions and check dimensions of groove specifications.

[0064] The identifying and extracting module 720 is configured to identify the groove type specification according to the groove type specification code and marking method, and extract the groove type reference size from the reference size library. Among them, the reference dimensions in the reference dimension library are preset according to the groove specifications. Moreover, before ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com