Lithium ion battery electrolyte and lithium ion battery

A lithium-ion battery, electrolyte technology, applied in the field of applied chemistry, can solve problems such as insufficient high pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

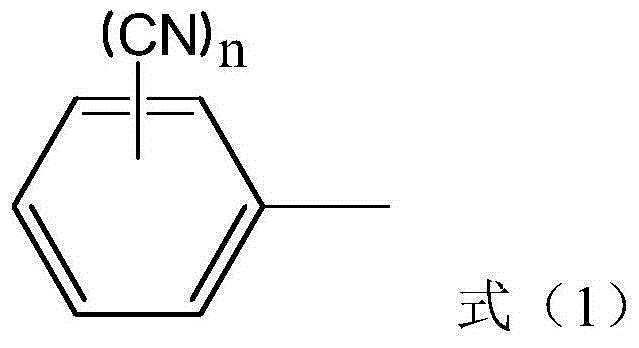

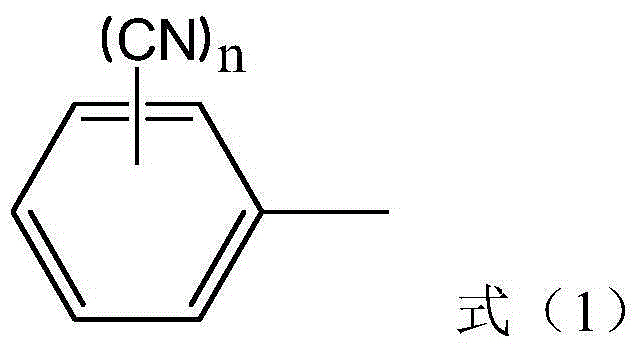

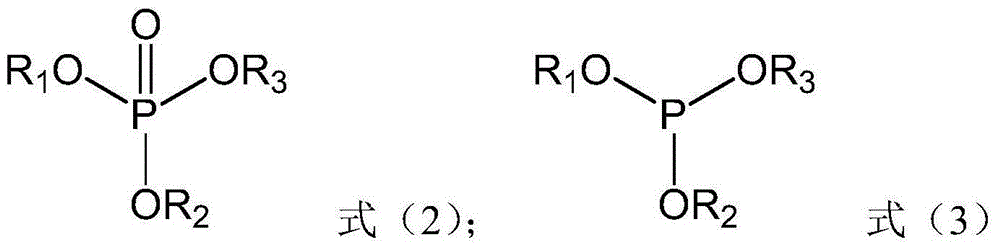

[0024] Among them, according to a particularly preferred embodiment of the present invention, the high-pressure additives include: 4-cyanophenoxy, bis(methoxy)phosphate, bis(4-cyanophenoxy), methoxy Phosphate, 4-cyanophenoxy, cyanomethoxy, methoxy phosphate, 3,5-dicyanophenoxy, methoxy, trifluoroethoxy phosphate, 4-cyano Phenoxy, Methoxy, Trifluoroethoxy Phosphate, Bis(4-cyanophenoxy), Trifluoroethoxy Phosphate, Bis(3,5-Dicyanophenoxy), Tris Fluoroethoxy phosphate, 4-cyanophenoxy, bis(methoxy) phosphite, bis(4-cyanophenoxy), methoxy phosphite, 4-cyanophenoxy , cyanomethoxy, methoxy phosphite, 3,5-dicyanophenoxy, methoxy, trifluoroethoxy phosphite, 4-cyanophenoxy, methoxy, Trifluoroethoxyphosphite, bis(4-cyanophenoxy), trifluoroethoxyphosphite, and bis(3,5-dicyanophenoxy), trifluoroethoxyphosphite at least one of phosphate esters. More preferably, the high pressure additives include 3,5-dicyanophenoxy, methoxy, trifluoroethoxy phosphite, 4-cyanophenoxy, methoxy, trifluoroeth...

Embodiment 1

[0039] The electrolyte solution is configured in the glove box, which is filled with nitrogen with a purity of 99.999%, the water and oxygen content in the glove box is controlled at 6 A 1mol / L electrolyte solution is formed. Then add 1 gram of high-pressure additive (3,5-dicyanophenoxy, methoxy, trifluoroethoxy phosphite, as shown in the following formula) and 1 gram of 1,3-propanesulfonate to the above electrolyte solution Lactone, mixed uniformly to obtain the high-pressure non-aqueous electrolyte solution of the present embodiment.

[0040]

[0041] Wherein, the synthetic method of 3,5-dicyanophenoxy group, methoxyl group, trifluoroethoxy phosphite comprises: in a 1000ml three-necked flask, feed nitrogen to displace air, add 3,5- Dicyanophenol (432g, 3mol), phosphorus trichloride (137g, 1mol) was added dropwise and stirred, heated to reflux for 5-6h after the dropwise addition was completed, then decompressed distillation to remove HCl gas, column purification to obtain...

Embodiment 2

[0044] Prepare high-voltage non-aqueous electrolyte and lithium-ion battery according to the method of Example 1, the difference is that the high-voltage additive is 4-cyanophenoxy, methoxy, trifluoroethoxy phosphite, as shown in the following formula.

[0045]

[0046] Wherein, the synthetic method of 4-cyanophenoxy group, methoxyl group, trifluoroethoxy phosphite comprises: in a 1000ml there-necked flask, feed nitrogen to displace air, add 4-cyanophenol (357g, 3mol), phosphorus trichloride (137g, 1mol) was added dropwise and stirred, and after the dropwise addition was completed, it was heated to reflux for 5-6h, then the HCl gas was removed by distillation under reduced pressure, and the column was purified to obtain three (4-cyanophenoxy) Phosphite (335 g, 0.87 mol). Then three (4-cyanophenoxy) phosphite (335g, 0.87mol), add methanol (28g, 0.87mol) and trifluoroethanol (87g, 0.87mol), and stir reflux reaction 5-6h, then The 4-cyanophenol was removed by distillation und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com