An offshore sandwich steel pipe pile foundation

A sandwich steel pipe and pile foundation technology, which is applied in infrastructure engineering, coatings, anti-corrosion coatings, etc., can solve problems such as poor compressive capacity and other physical and mechanical indicators, reduce the service life of pipe piles, and require high construction equipment. Natural erosion and instability damage, prolong service life, considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

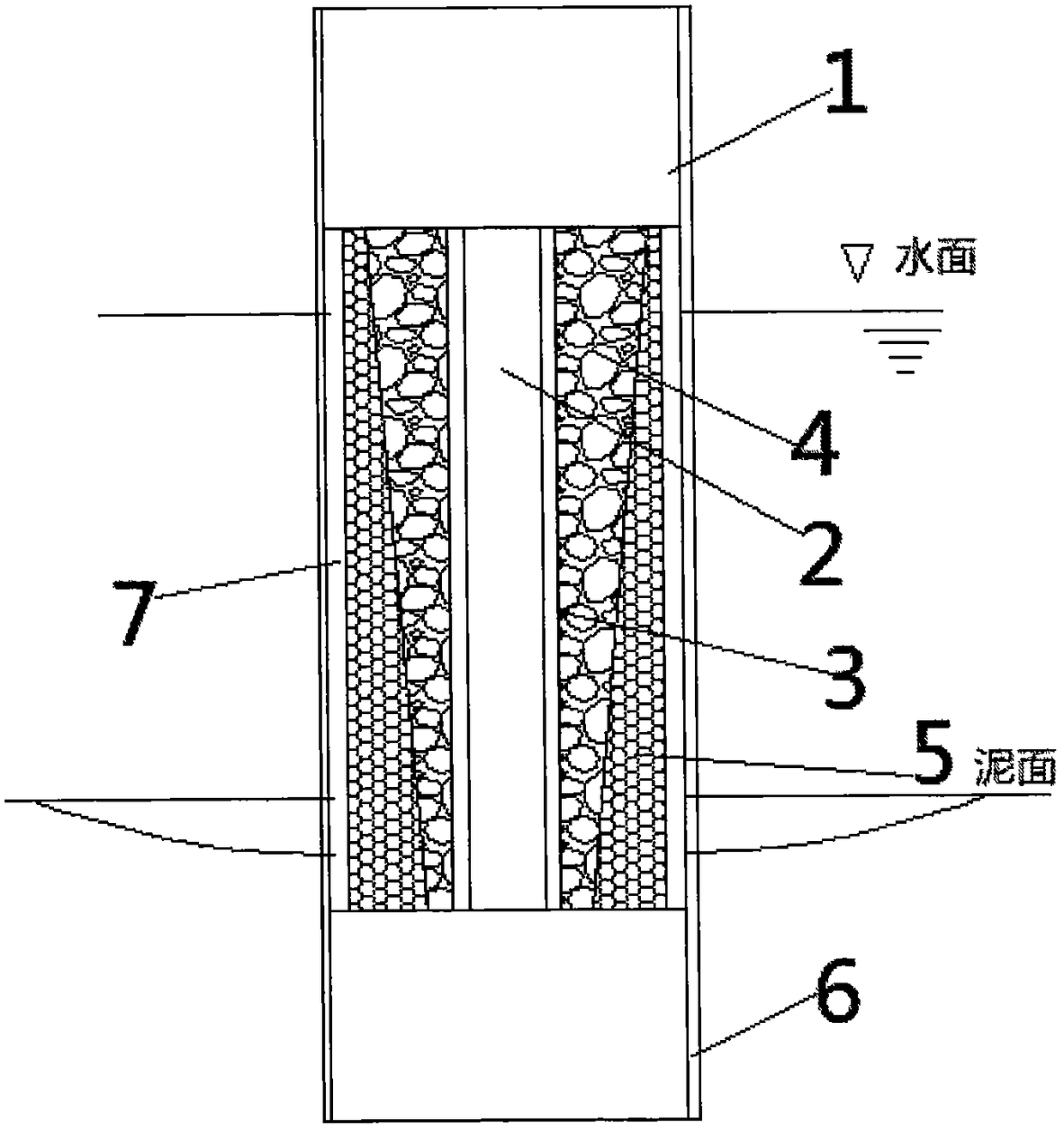

[0021] Such as figure 1 As shown, the embodiment of the present invention provides an offshore sandwich steel pipe pile foundation, including an outer steel pile 1 and an inner steel pipe 2, the inner steel pipe 2 is installed in the outer steel pile 1, and the inner steel pipe 2 is externally connected with a concrete reinforcement layer 4 The concrete reinforcement layer 4 is a hollow circular platform structure, and the diameter of the hollow circular platform decreases sequentially from top to bottom, the concrete reinforcement layer 4 is provided with a bamboo winding layer 5, and the concrete reinforcement layer 4 is provided with three T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com