A method for preparing silicon carbide porous ceramics by microwave in-situ sintering technology

A technology of porous ceramics and silicon carbide, applied in the field of preparation of silicon carbide porous ceramics, can solve the problems of unfavorable rapid acquisition and further popularization and application of silicon carbide porous ceramics, complex process, high cost, good electromagnetic response and simple preparation process. , fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0051] Take 24g of activated carbon, 60g of nano-silica, 28g of silicon powder, 0.56g of kaolin and 5.6g of thermoplastic phenolic resin, put them together into a ball mill jar, and ball mill for 1 hour at 500rpm to make the powder evenly mixed. Then take 10 g of the mixed powder and heat press it at 100° C. and 100 MPa for 10 minutes to obtain a green body.

[0052] After the pressed green body is moved into the high-energy microwave resonant cavity, the vacuum is evacuated to about 10kPa. Set the microwave irradiation power to 5kW, start to keep warm when the temperature reaches 1400°C, turn off the microwave after 1h, let the reaction system cool down to room temperature with the furnace, and then take out the sample. The obtained porosity is 60%, the flexural strength is 15MPa, and the density is 0.9g / cm 3 SiC porous ceramics.

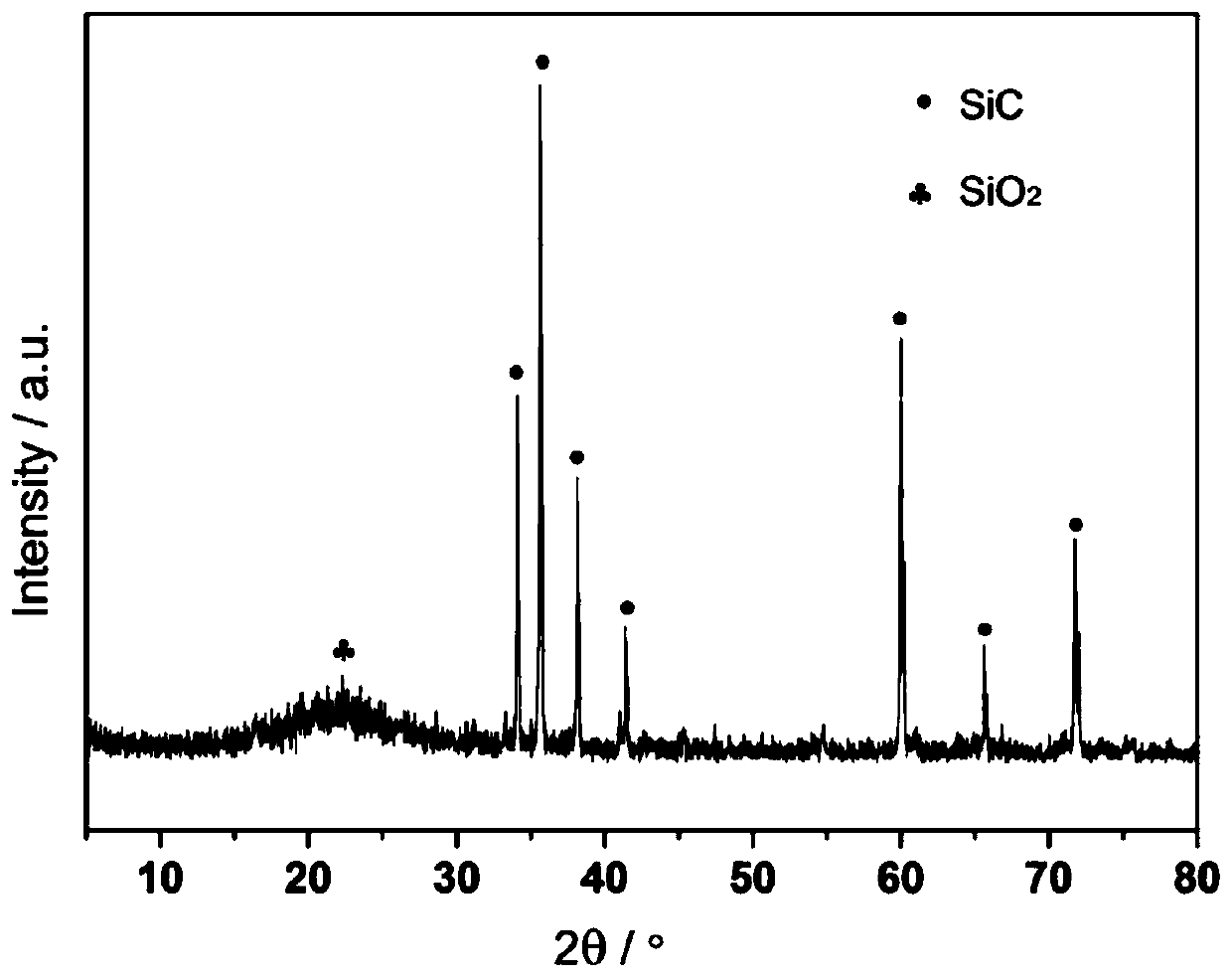

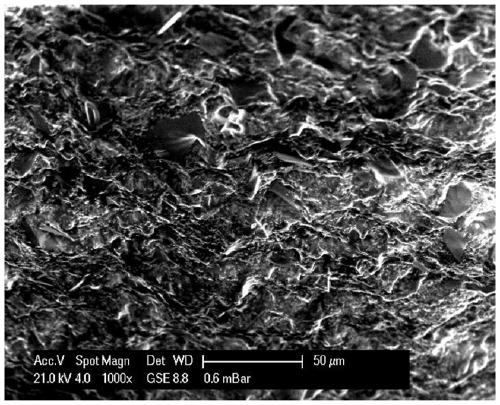

[0053] The crystal phase of silicon carbide ceramics was determined by X-ray powder diffractometer (XRD) (see figure 1 ), the pore structure wa...

Embodiment example 2

[0055] The preparation method of the green body is the same as that of the implementation example 1.

[0056] After the pressed green body is moved into the high-energy microwave resonant cavity, the vacuum is evacuated to about 20kPa. Set the microwave irradiation power to 5.5kW, and start to keep warm when the temperature reaches 1500°C. After 2h, turn off the microwave oven, let the reaction system cool down to room temperature with the furnace, and then take out the sample. The obtained porosity is 45%, the flexural strength is 25MPa, and the density is 1.3g / cm 3 SiC porous ceramics.

Embodiment example 3

[0058] Take 24g of activated carbon, 60g of nano-silica, 28g of silicon powder, 1.12g of kaolin, 1.12g of alumina and 11.2g of thermoplastic phenolic resin, put them together into a ball mill jar, and ball mill for 2 hours at 500rpm to make the powder evenly mixed. Then take 10g of the mixed powder and heat press it at 100°C and 100MPa for 10min to obtain a green compact.

[0059] After the pressed green body is moved into the high-energy microwave resonant cavity, the vacuum is evacuated to about 10kPa. Set the microwave irradiation power to 6kW, and start to keep warm when the temperature reaches 1600°C. After 3 hours, turn off the microwave oven, let the reaction system cool down to room temperature with the furnace, and then take out the sample. The obtained porosity is 38%, the flexural strength is 27MPa, and the density is 1.3g / cm 3 SiC porous ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com