Method for increasing oil recovery rate through self-generation carbon dioxide system after polymer flooding

A carbon dioxide, recovery factor technology, applied in chemical instruments and methods, production fluids, earthwork drilling, etc., to achieve the effects of inhibiting viscous fingering, changing the direction of liquid flow, and expanding sweep efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

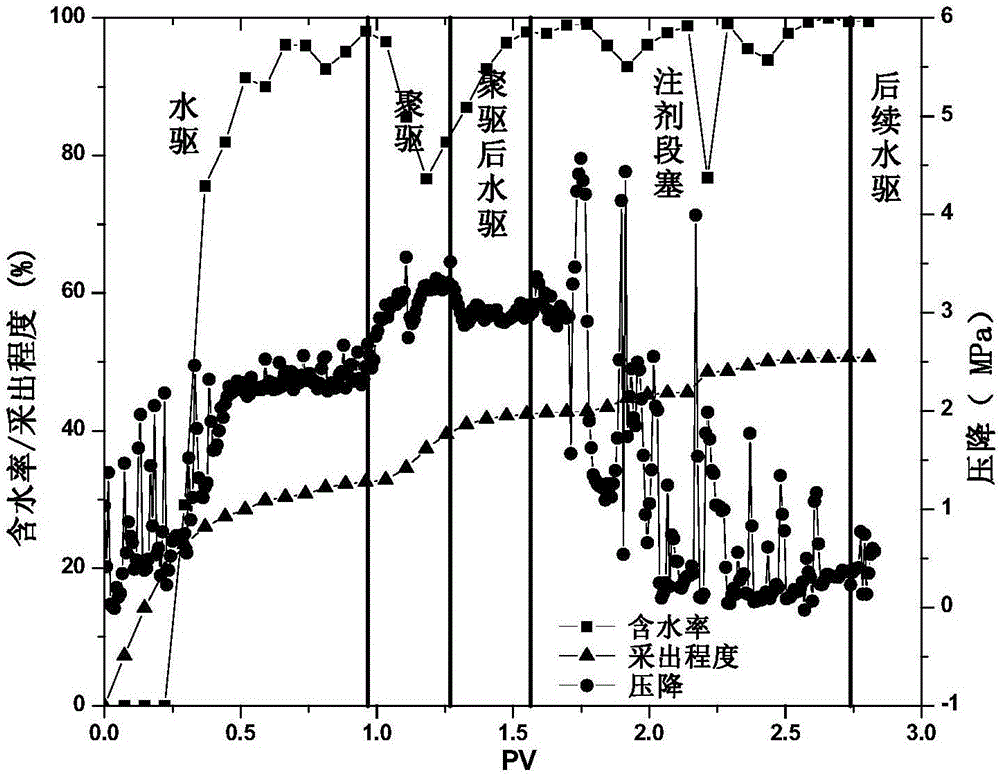

Embodiment 1

[0054] (1) Select the compressed homogeneous artificial core model, the gas permeability is 500mD, the length of the core is 29.55cm, and the cross-sectional area is 4.30*4.35cm 2 .

[0055] (2) Put the core in an oven at 105°C, and dry it until it reaches a constant weight, and record the dry weight as 1024.93g;

[0056] (3) The model was vacuumed for 8 hours, saturated with simulated formation water, the measured pore volume was 135.43mL, and the calculated porosity was 24.50%;

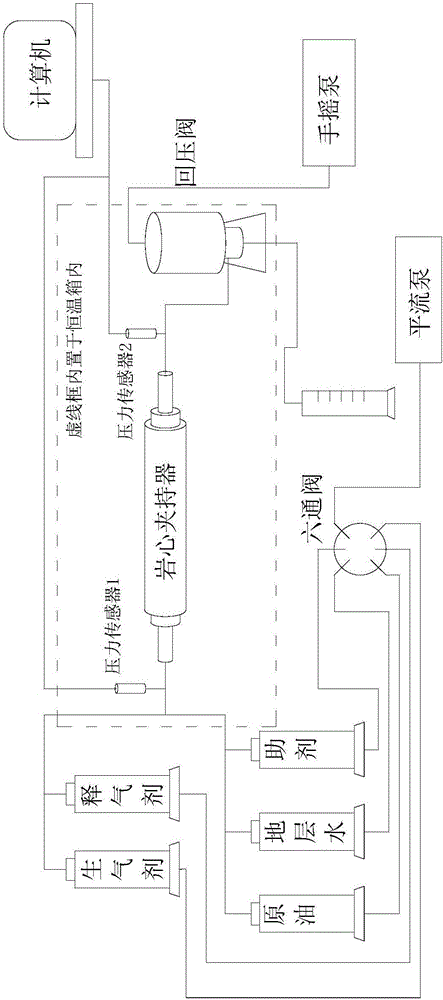

[0057] (4) According to figure 1 Install the displacement experimental equipment and test the tightness;

[0058] (5) Saturated crude oil, oil drives water until the outlet end does not produce water, and the original oil saturation under the state of bound water is calculated to be 64.98%;

[0059] (6) Water flooding with a flow rate of 1.0mL / min, when the water content at the outlet reaches 98%, stop the water flooding;

[0060] (7) Inject a 0.3 PV polymer (polyacrylamide, molecular weight 15 ...

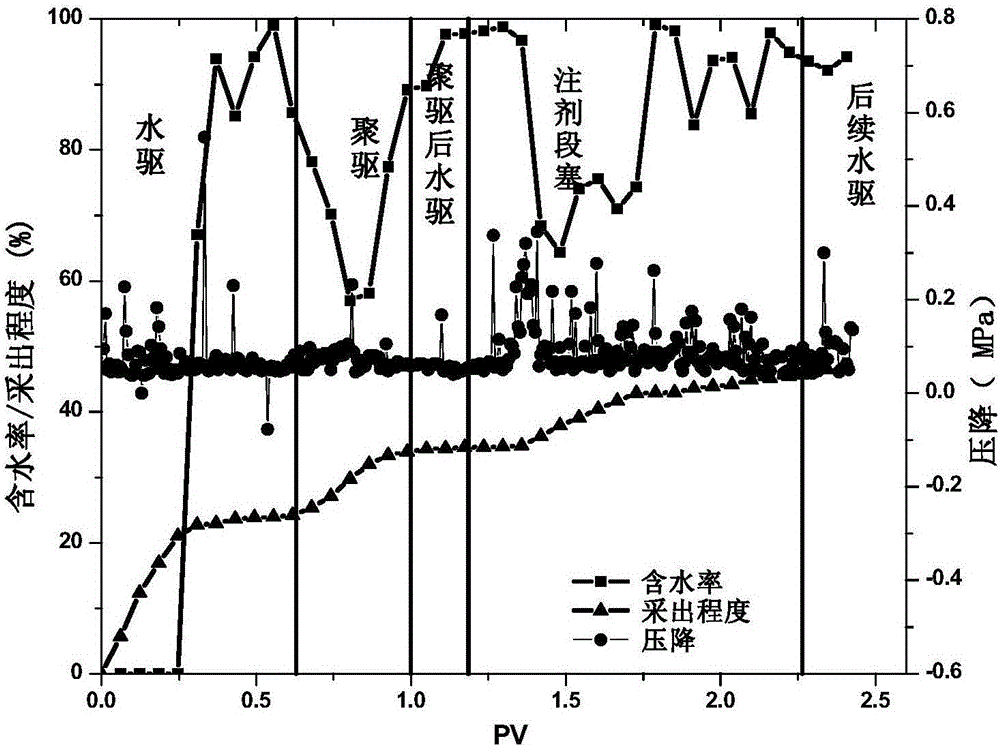

Embodiment 2

[0066] (1) Select the heterogeneous artificial core model in the suppressed layer, the gas permeability is 500 / 2500 / 5000mD, the length of the core is 29.55cm, and the cross-sectional area of the high permeability layer is 4.50*1.47cm 2 , the cross-sectional area of the medium permeation layer is 4.50*1.52cm 2 , the cross-sectional area of the low-permeability layer is 4.50*1.48cm 2 ;

[0067] (2) Put the core in an oven at 105°C, and dry it until constant weight, and record the dry weight as 1053.47g;

[0068] (3) The model was vacuumed for 8 hours, saturated with simulated formation water, the measured pore volume was 162.01mL, and the calculated porosity was 27.25%;

[0069] (4) Install the displacement experimental equipment and test the tightness;

[0070] (5) Saturated crude oil, oil drives water until the outlet end does not produce water, and the original oil saturation under the state of irreducible water is calculated to be 71.36%;

[0071] (6) Water floodin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com