A CO shift low-temperature heat utilization method and a CO shift process using the method

A process and heat exchanger technology, which is applied in the field of CO conversion devices, can solve the problems of complex process flow, unreasonable use of the heat of the steam generator sewage, and large fluctuation of influence, so as to optimize the heat exchange network, save operating costs and Occupying area and good operation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

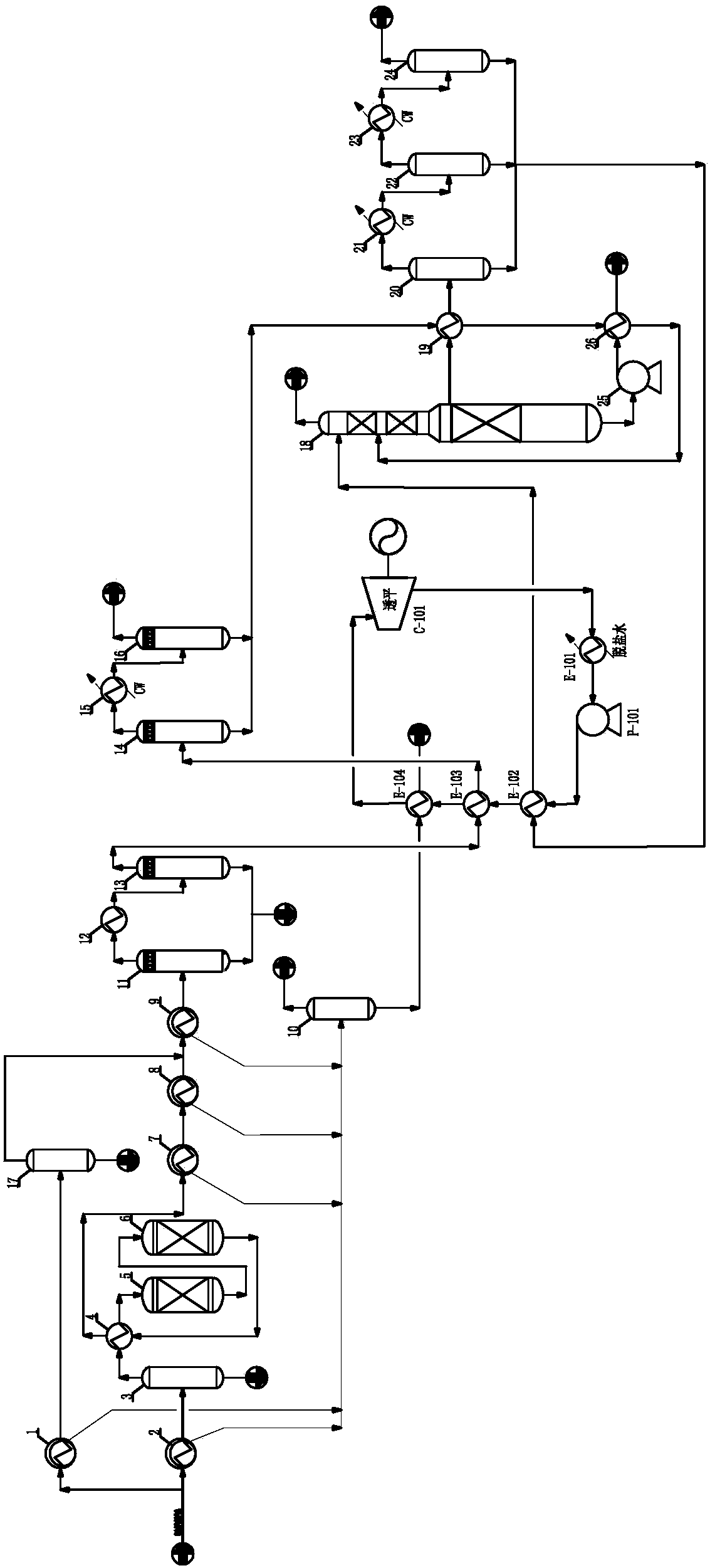

[0035] The 240°C, 6.3MPaG crude synthesis gas from the gasification unit enters the shift unit and is divided into two paths, one for shifted gas and the other for non-shifted gas. The ratio of shifted gas to non-shifted gas is distributed according to the requirements of downstream process equipment.

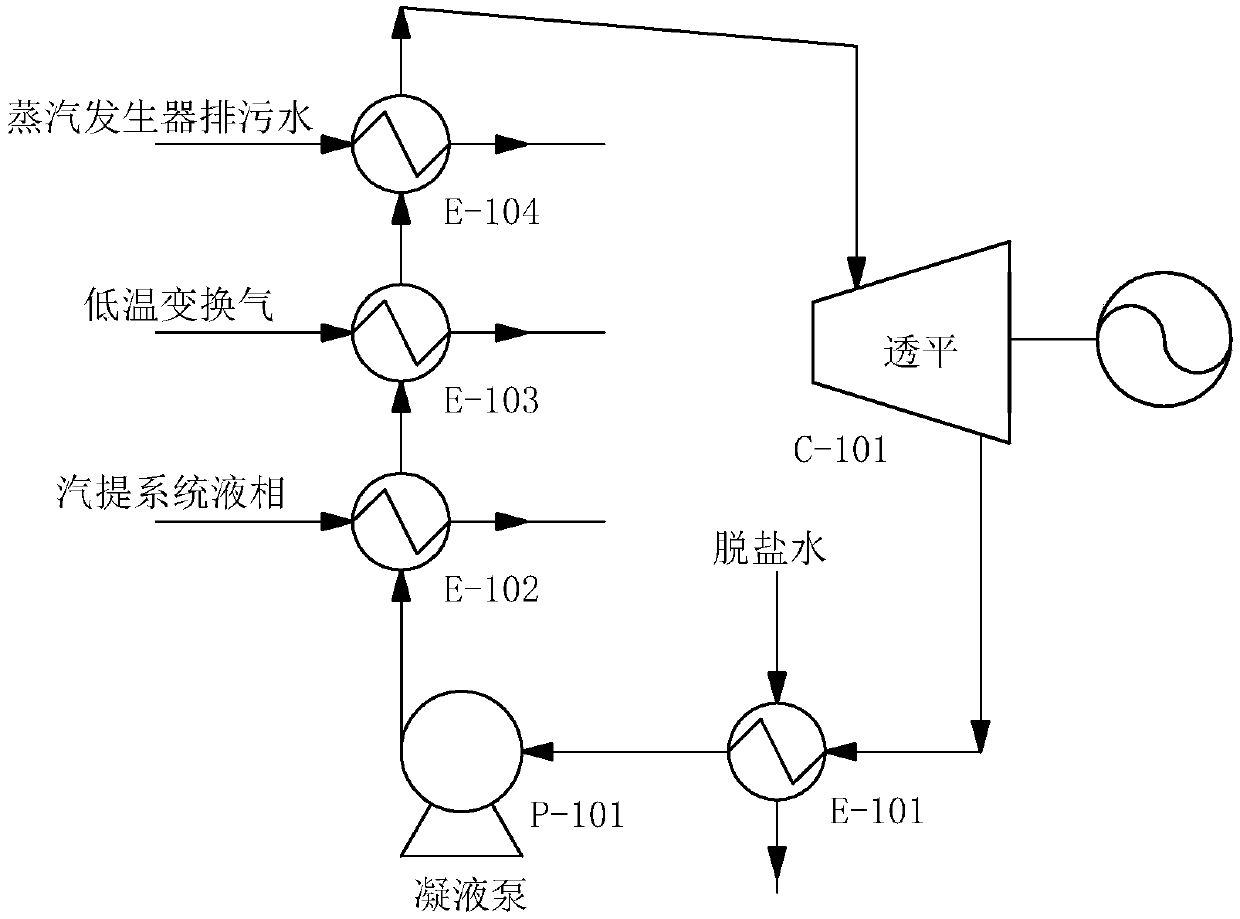

[0036]The shifted gas is heat-exchanged by No. 1 medium and low pressure steam generator 2, and gas-liquid separated by No. 1 gas-liquid separator 3, and then heated to 250-300°C by the shift furnace inlet heater-medium-pressure steam superheater 4, and sent to Enter the detoxification tank 5 to remove impurities such as dust contained in the converted gas. The detoxified crude synthesis gas enters the shift furnace 6 for CO shift reaction to obtain high-temperature shift gas with a temperature of 420-440°C. The high-temperature shift gas leaving the shift furnace 6 first passes through the shift furnace inlet heater-medium-pressure steam superheater 4 to overheat the 3.0-3.2MP...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap