Acid etching testing method of macrostructure and defect of steels

A technology of low-magnification structure and inspection method, which is applied in the field of steel low-magnification structure inspection, steel low-magnification structure and defect acid corrosion inspection, and can solve the problems of poor cold acid corrosion ability and hot acid corrosion too deep, etc., to achieve safety High reliability, reduced labor costs, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

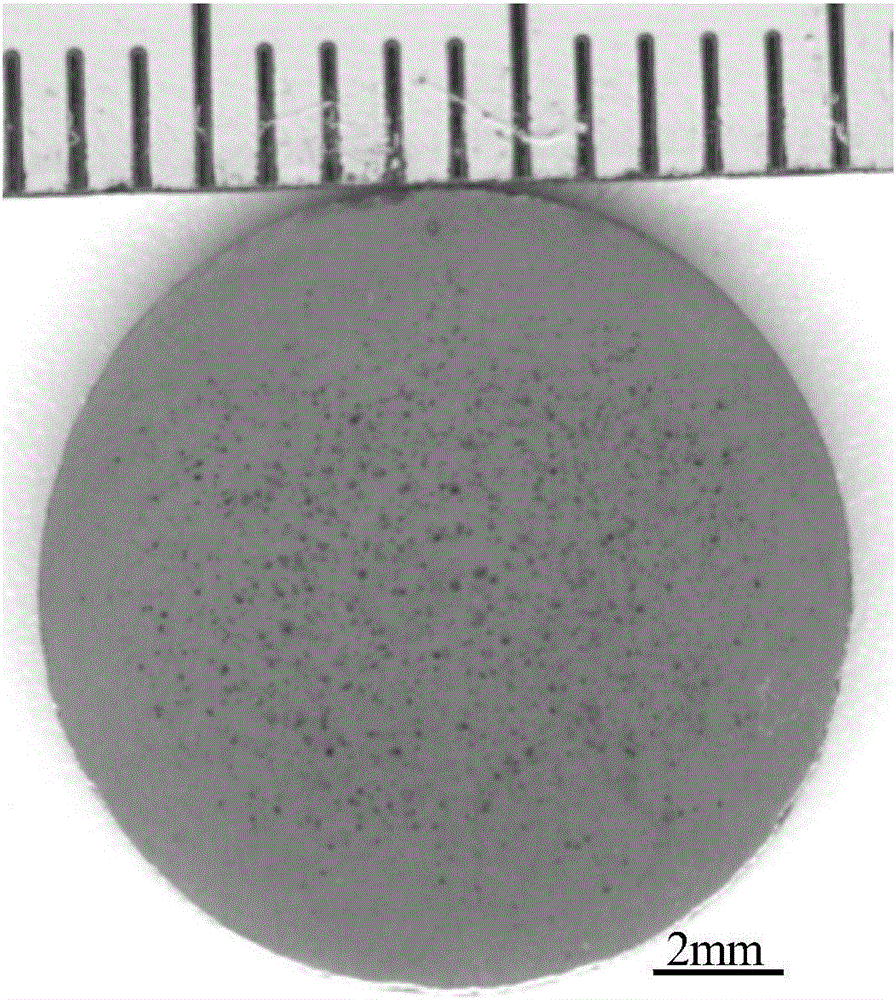

[0031] In this example, a low-magnification sample of 50CrVA with a size of φ13 mm was cut and prepared, and the defect of the sample was generally level 4 loose. Select a 50ml beaker container, prepare 50wt% hydrochloric acid aqueous solution, adjust the solution temperature to 65°C, immerse the prepared sample in the above prepared solution, corrode for 15min, and wipe the surface corrosion with 10wt% sodium bicarbonate solution after taking it out product, followed by drying with alcohol. Grind and polish the corroded sample with 800#, 1000#, 1200#, 2000# sandpaper, leaving traces of surface looseness, and use 5wt% nitric acid alcohol solution to corrode for 30s, and the low-magnification structure morphology is as follows figure 1 shown.

Embodiment 2

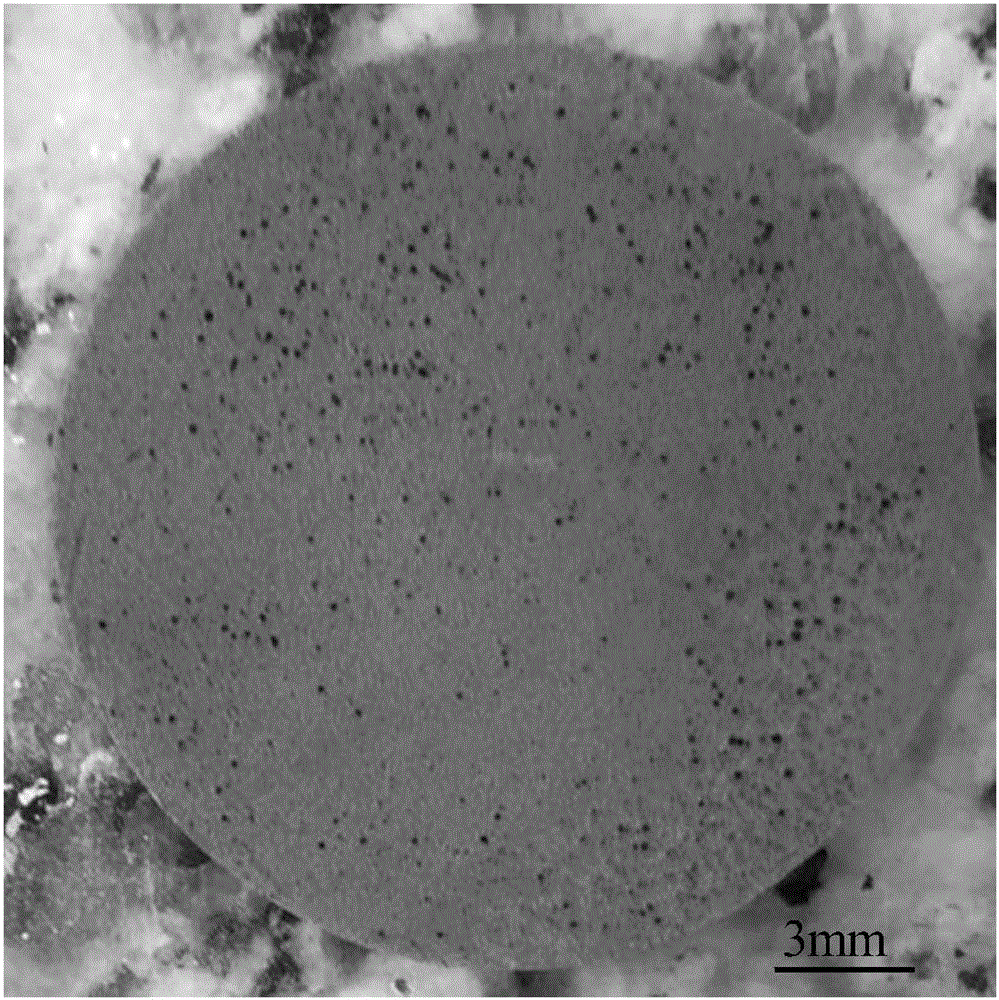

[0033] In this example, a low-magnification sample of 30CrMnSiA with a size of φ20 mm was cut and prepared, and the defect of the sample was generally level 4 loose. Select a 50ml beaker container, prepare 50wt% hydrochloric acid aqueous solution, adjust the solution temperature to 65°C, immerse the prepared sample in the above prepared solution, corrode for 15min, and wipe the surface corrosion with 10wt% sodium bicarbonate solution after taking it out product, followed by drying with alcohol. Grind and polish the corroded sample with 800#, 1000#, 1200#, 2000# sandpaper, leaving traces of surface looseness, and use 5wt% nitric acid alcohol solution to corrode for 40 seconds, and the low-magnification structure morphology is as follows figure 2 shown.

[0034] The results of the examples show that the present invention speeds up the corrosion rate and improves the corrosion ability by combining thermal erosion and cold erosion, and can truly reflect the loose defects on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com