Electrolyte of austenitic stainless steel and application thereof

A technology of austenitic stainless steel and electrolyte, applied in the preparation of test samples, instruments, measuring devices, etc., can solve the problems of poor corrosion effect, health damage of experimenters, and difficulty in controlling corrosion effect, and achieve stable corrosion effect , no irritating smell, good electrolytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] An electrolyte for austenitic stainless steel.

[0044] The preparation method of the electrolyte: take 25g of chromium trioxide and 75ml of distilled water, successively import the chromium trioxide and distilled water into a glass container and stir evenly with a glass rod, then add 5g of sodium dodecylbenzenesulfonate, stir Evenly, that is.

[0045] The electrolyte includes 28.10% by mass of chromic acid and 4.76% by mass of sodium dodecylbenzenesulfonate.

Embodiment 2

[0047] An on-site metallographic detection method for austenitic stainless steel.

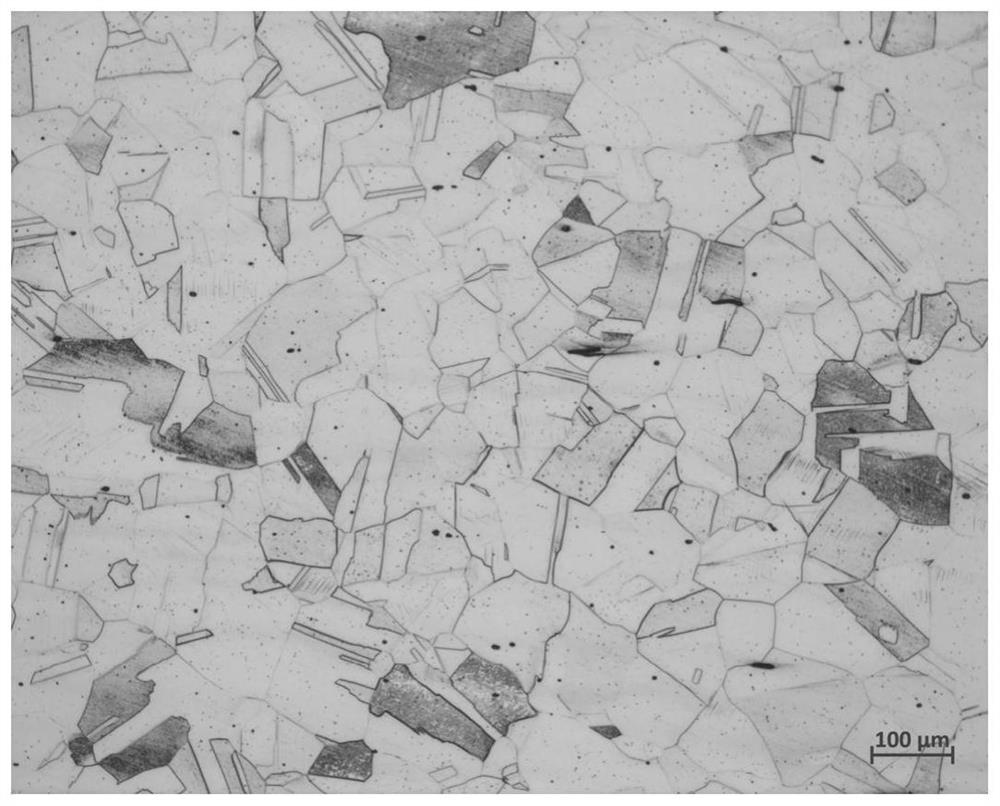

[0048]The stainless steel material SA-965MF 316H is used as the sample. The stainless steel of SA-965MF 316H is nuclear-grade austenitic stainless steel. It is roughly ground and finely ground by portable grinding and abrasive paper, and then mechanically polished with diamond spray. The outer surface of the polished sample is used as the surface to be tested, and then cleaned with absolute ethanol, and electrolytic corrosion is performed with an on-site electrolytic instrument PTI-330D. First, the electrolyte prepared in Example 1 is introduced into the electrolyte supply bottle, and the electrode is connected to the battery. , connect the anode and cathode respectively to the surface to be tested of the sample, pinch the electrolyte supply bottle, so that the electrolyte fully contacts the surface to be tested, and perform electrolysis. The electrolysis parameters used are: voltage 10V, curren...

Embodiment 3

[0051] An on-site metallographic detection method for austenitic stainless steel.

[0052] A stainless steel material of SA-312MTP 316H was used as the sample, and the stainless steel of SA-312MTP 316H was a nuclear-grade austenitic stainless steel, and the detection method was the same as in Example 2.

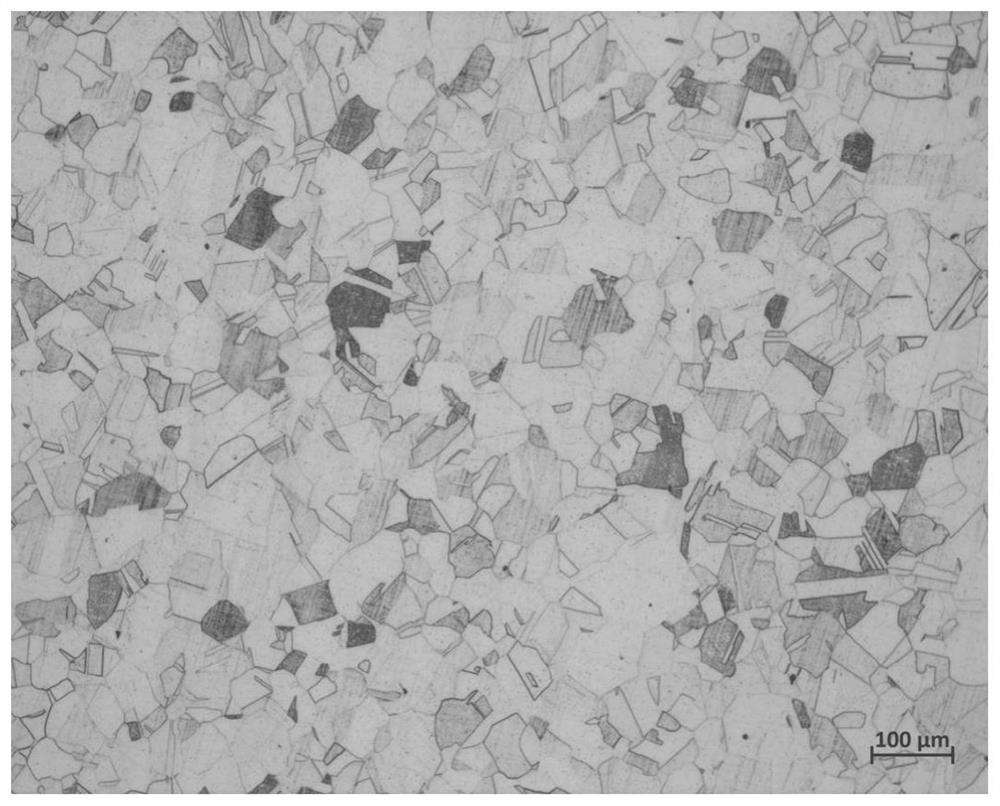

[0053] The grain size detection was carried out, and the results were as follows: the detection result of the intercept point method was grade 5, the detection result of the area method was grade 5, and the detection result of the comparison method was grade 5, and the detection results of the three detection methods stipulated in the standard were highly consistent. The structure is austenite and a small amount of carbide, such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com