Method and system for monitoring the thickness of turbine stator blades in a blast furnace gas waste heat recovery device

A waste heat recovery device, blast furnace gas technology, applied in safety devices, neural learning methods, information technology support systems, etc., can solve the problem of inability to meet the requirements of stable operation of TRT devices, lack of configuration of small TRT devices, expensive vibration analysis system, etc. problems, to achieve the effect of improving maintenance efficiency, reducing manpower and material resources input, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

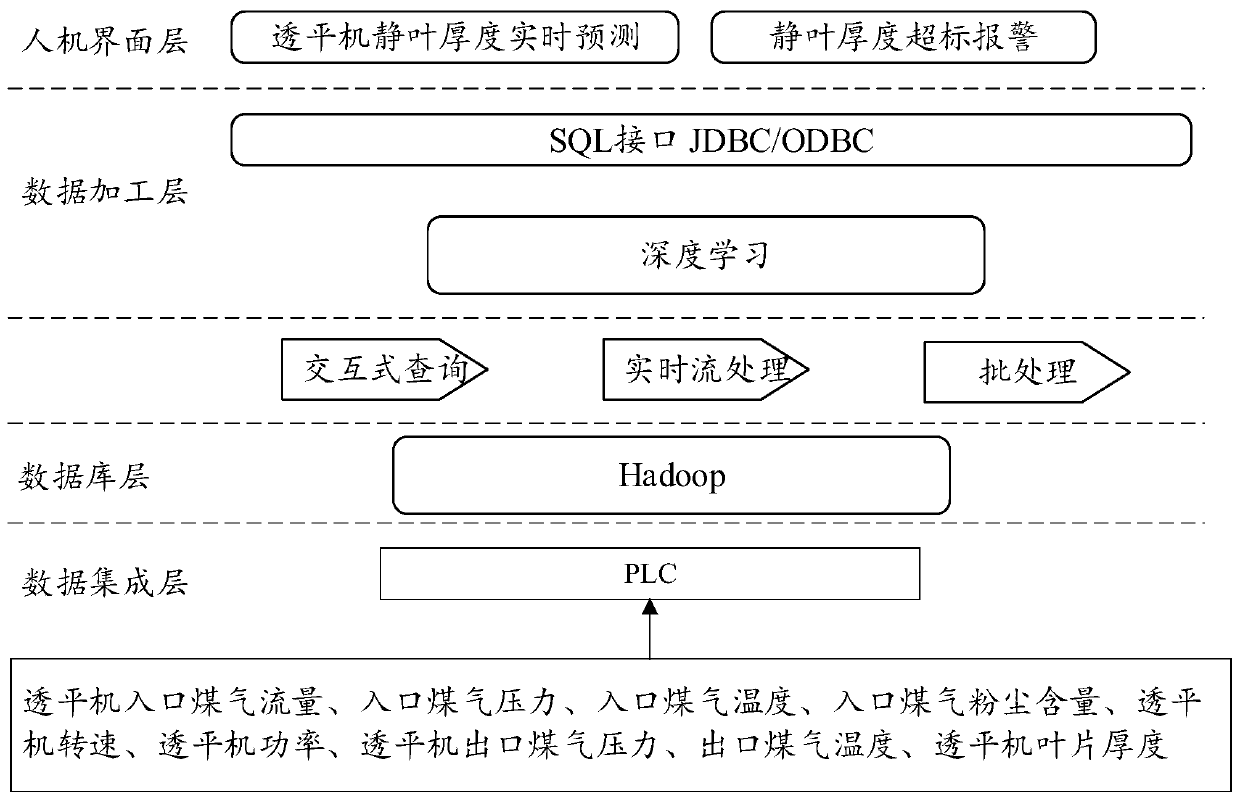

[0049] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

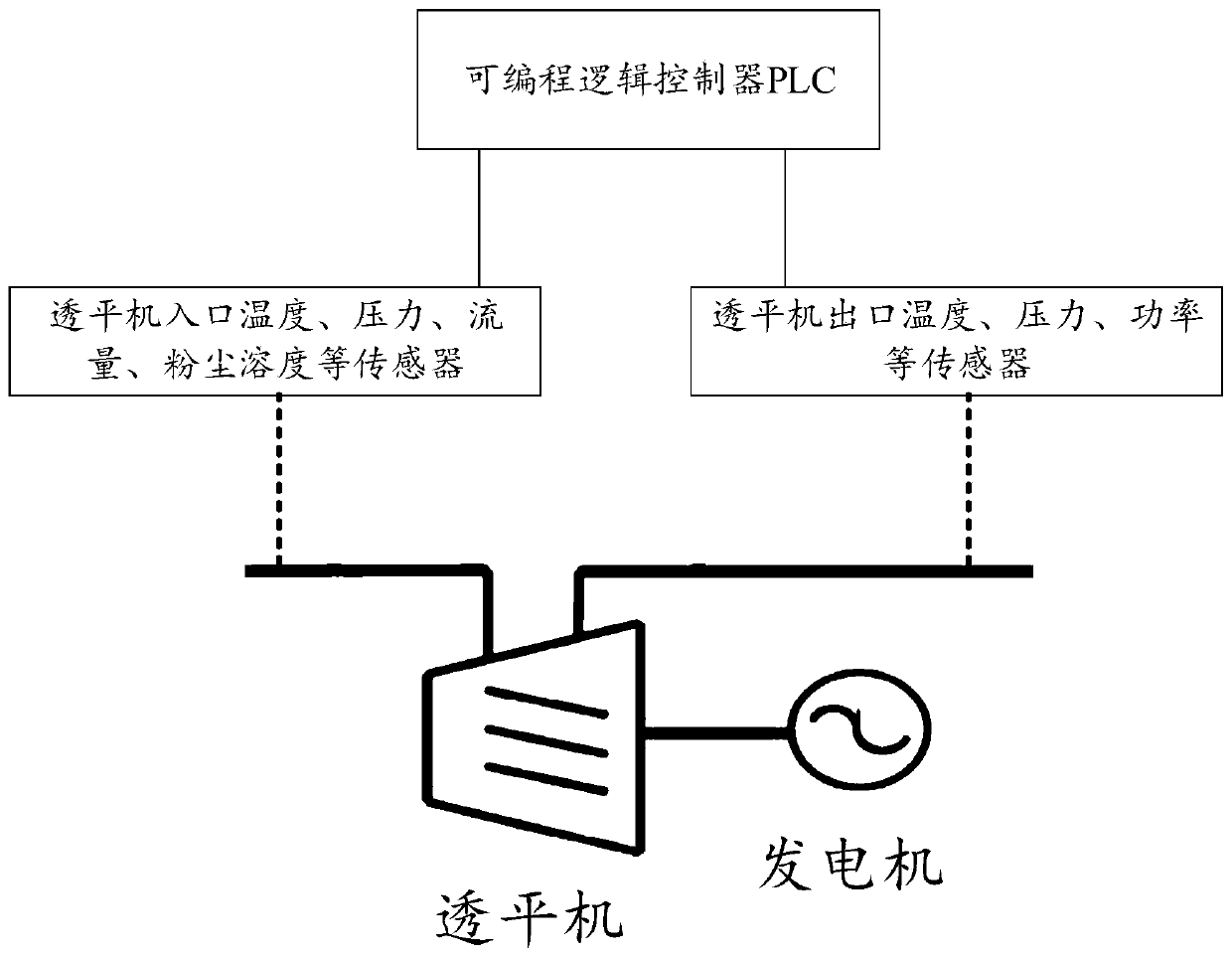

[0050] Such as figure 1 Shown is a schematic diagram of the data acquisition module of the present invention. The data acquisition of the thickness monitoring of the turbine vane of the blast furnace gas residual pressure power generation device is completed through the programmable controller and sensors such as flow, pressure, temperature, and dust solubility meters. The thickness of the turbine vane is completed through laboratory testing. Through the collection of a large number of turbine operating data, the training data set of the turbine stator blade thickness monitoring method and system is constructed.

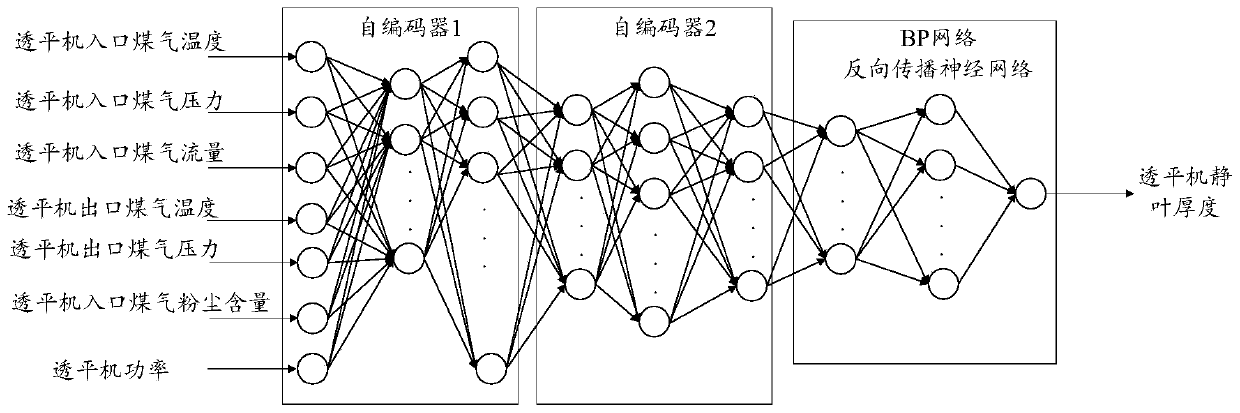

[0051] Such as figure 2 Shown is a schematic diagram of the process of the deep learning algorithm of the present invention. Firstly, the inlet gas flow rate, inlet gas pressure, inlet gas te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com