High-strength steel sheet and production method for same, and production method for high-strength galvanized steel sheet

A technology of high-strength steel sheet and manufacturing method, applied in manufacturing tools, hot-dip plating process, coating and other directions, can solve problems such as poor shape, reduced mass production efficiency, increased deviation, etc., and achieves high utilization value and improved fuel efficiency. , the effect of excellent ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

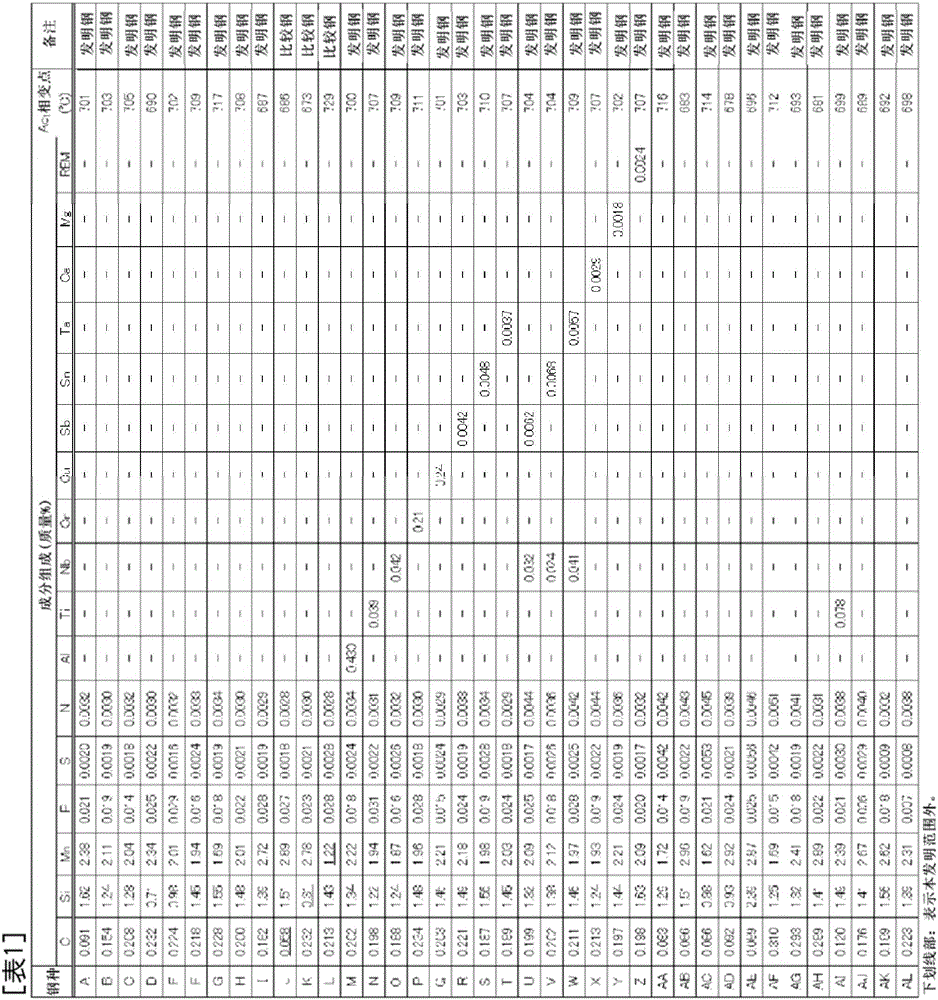

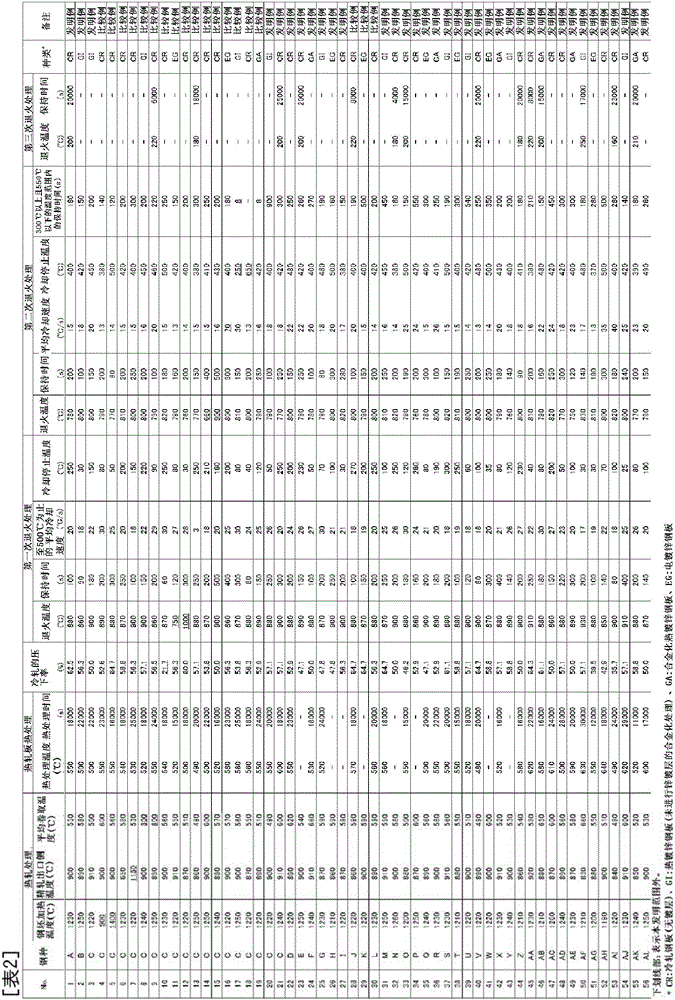

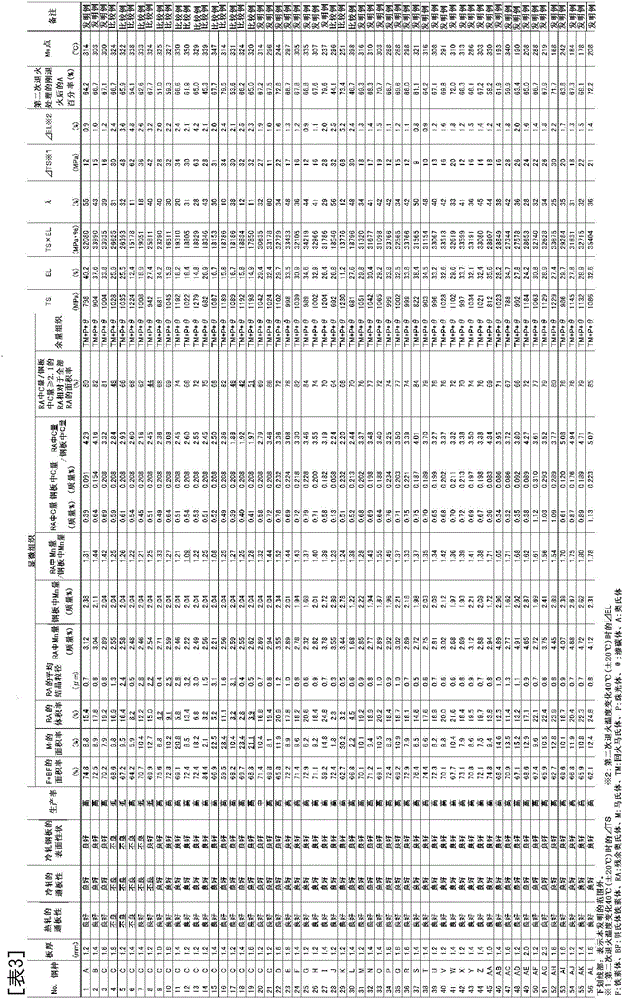

[0171] The steel having the composition shown in Table 1 and the balance consisting of Fe and unavoidable impurities was smelted in a converter, and a billet was produced by a continuous casting method. The obtained steel slab was heated under the conditions shown in Table 2, and hot rolled to obtain a steel sheet. Then, the steel sheet is subjected to pickling treatment. Then, for Nos. 1-22, 24, 25, 28, 30, 31, 33, 35-40, 42, 44-56 shown in Table 2, the steel sheets were hot-rolled under the conditions shown in Table 2. Heat treatment. For Nos. 31, 33, 35-40, 42, 44, the hot-rolled sheet was subjected to pickling treatment after heat treatment.

[0172] Next, after cold rolling the steel sheet under the conditions shown in Table 2, the steel sheet was subjected to two or three annealing treatments under the conditions shown in Table 2 to obtain a high-strength cold rolled steel sheet (CR).

[0173] Furthermore, a part of the high-strength cold-rolled steel sheet (CR) is galvani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com