Method for producing optical member and curable resin composition used therein

A curable resin and manufacturing method technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as discharge, yield drop, substrate deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

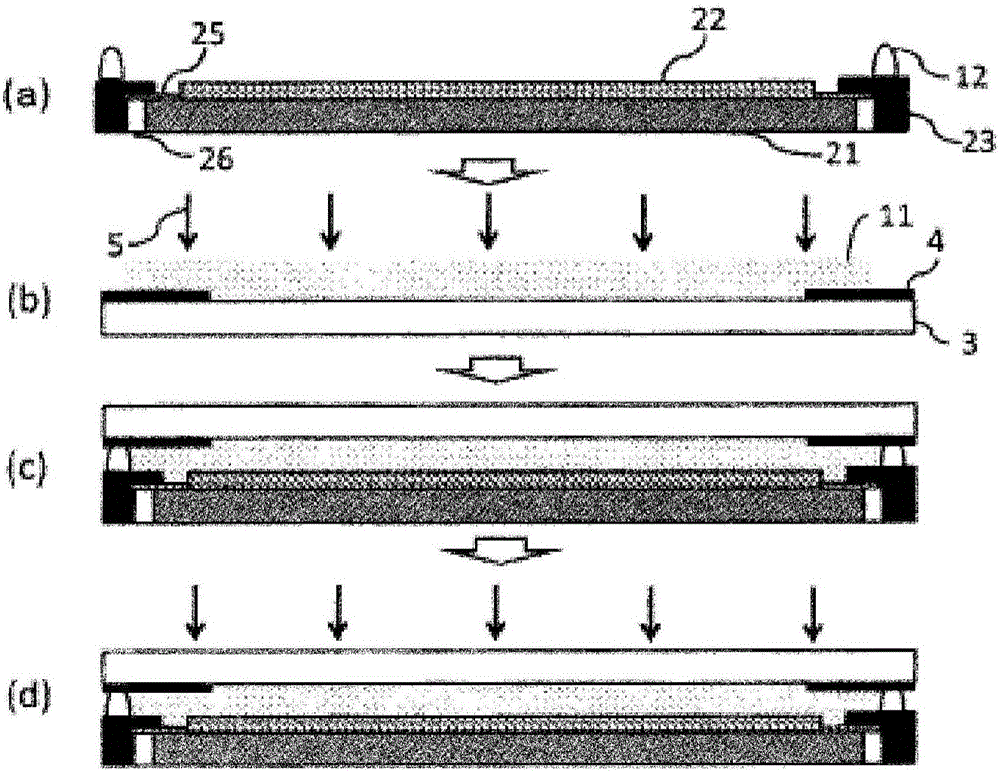

[0057] figure 1 It is a process drawing which shows 1st Embodiment of the manufacturing process of the optical member of this invention.

[0058] This method is a method of obtaining an optical member (image display device) by bonding the liquid crystal display unit 1 and the protective plate 2 together.

[0059] The liquid crystal display unit 1 is a liquid crystal display unit in which a liquid crystal material is sealed between a pair of substrates on which electrodes are formed, and includes a polarizing plate, a driving circuit, a signal input cable, and a backlight unit.

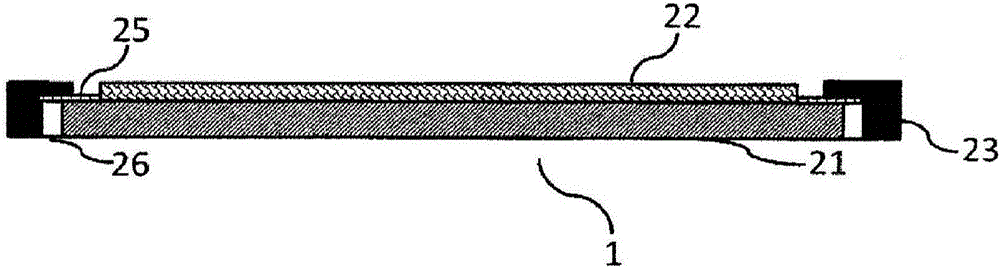

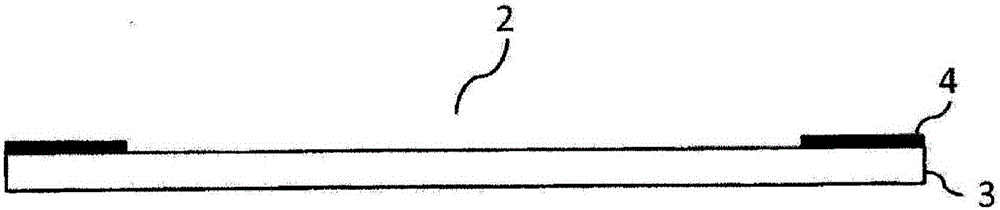

[0060] figure 2 It is a cross-sectional view showing a main part of an example of the liquid crystal display unit 1 . Such as figure 2 As shown, the liquid crystal display unit 1 is configured as follows: a polarizing plate 22 is disposed on a liquid crystal display cell 21 , and a sealing body 23 is disposed on the liquid crystal display cell 21 so as to surround the polarizing plate 22 . Here, ...

no. 2 approach

[0165] The optical member of the present invention can also be produced by the second embodiment modified as follows from the first embodiment.

[0166] [Process A]

[0167] First, if Figure 5 As shown in (a), the 2nd curable resin composition 12 containing a (meth)acrylate (A) and a photoinitiator (B) is apply|coated on the surface on the guard plate 2 in which the light shielding part 4 was formed.

[0168] Here, like the first embodiment, in the present invention, the second cured material layer 14 is laminated between the liquid crystal display unit 1 and the protective plate 2 in the form of a linearly extending layer or a dot-like scattered layer, thereby forming In order to separate the inner area and the outer area of the filling chamber 17 filled with the first curable resin composition, at least a part of the partition wall is provided with a communicating portion connecting the inner area and the outer area of the filling chamber. Additionally, if Figure 4 ...

no. 3 approach

[0182] The optical member of the present invention can also be produced by the third embodiment modified as follows on the basis of the first embodiment and the second embodiment.

[0183] [Process A]

[0184] First, if Figure 6 As shown in (a), the second curable resin composition 12 containing (meth)acrylate (A) and photopolymerization initiator (B) is coated on the display surface of the liquid crystal display unit 1 and the protective plate 2. On the surface of the face of the light shielding part 4 .

[0185] Here, like the first embodiment, in the present invention, the second cured material layer 14 is laminated between the liquid crystal display unit 1 and the protective plate 2 in the form of a linearly extending layer or a dot-like scattered layer, thereby forming In order to separate the inner area and the outer area of the filling chamber 17 filled with the first curable resin composition, at least a part of the partition wall is provided with a communicating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com