A kind of porous heating film and preparation method thereof

A heating film and heating layer technology, applied in vacuum evaporation coating, application, tobacco and other directions, can solve the problems of electrical fatigue, resistance drift, and small atomization of metal wires, reduce local excessive current, and simplify the preparation process. , The effect of high sample pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

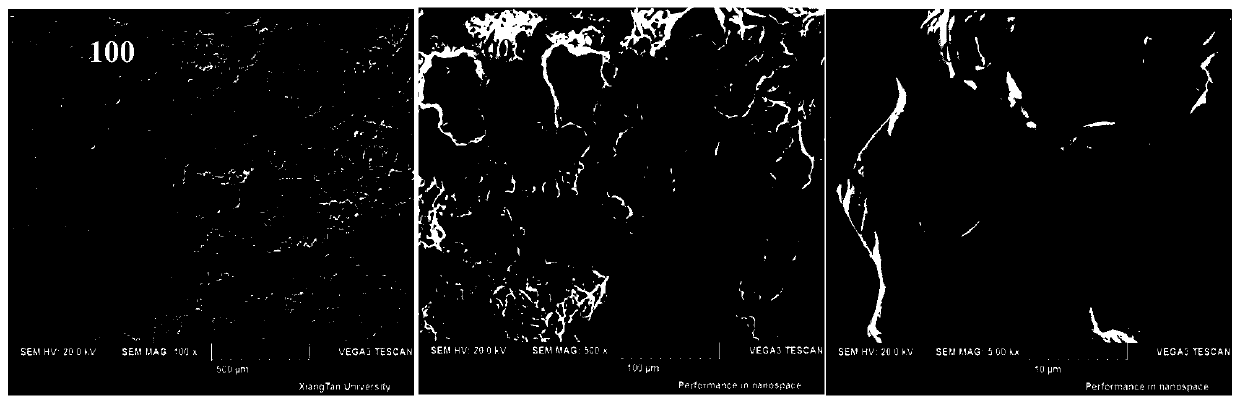

Image

Examples

Embodiment 1

[0057] An embodiment of the porous heating film of the present invention, the structure of each layer of the porous heating film: base layer-heating layer-stable catalytic layer is TiN-Ti-Au.

[0058] The preparation method of the porous heating film described in this embodiment comprises the following steps:

[0059] (1), substrate pretreatment:

[0060] First, the porous ceramic substrate with a porosity of 65% was polished with 2000-mesh water abrasive paper, then ultrasonically cleaned with an ultrasonic cleaner for 30 minutes, and finally dried at 600°C for 120 minutes in a muffle furnace;

[0061] (2), pre-coating treatment:

[0062] Put the substrate into the magnetron sputtering chamber to evacuate, the vacuum degree is 8×10 -4 Pa, heat treatment of the substrate, the temperature is 500°C;

[0063] (3), the formation of basal layer:

[0064] Sputter the pre-treated substrate with a sputtering power of 350W, a sputtering pressure of 0.22Pa, a pre-sputtering time of ...

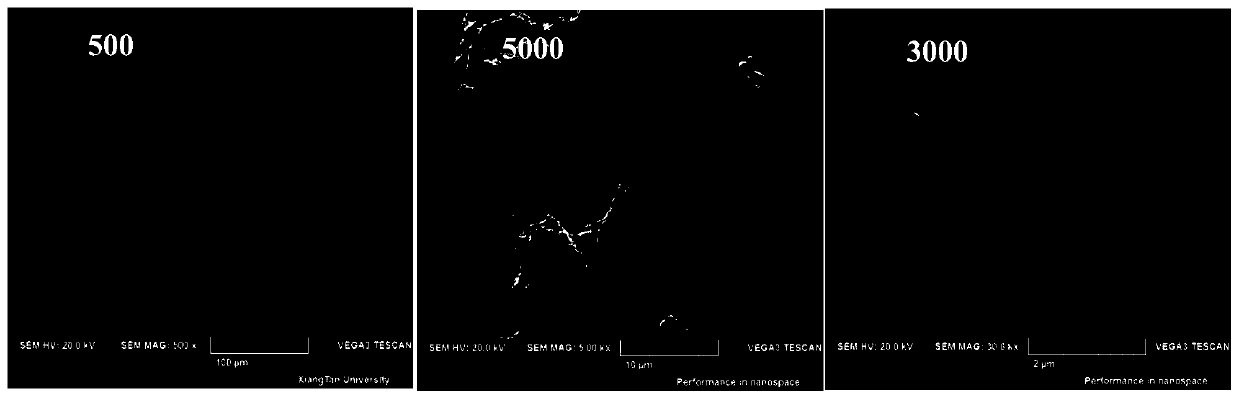

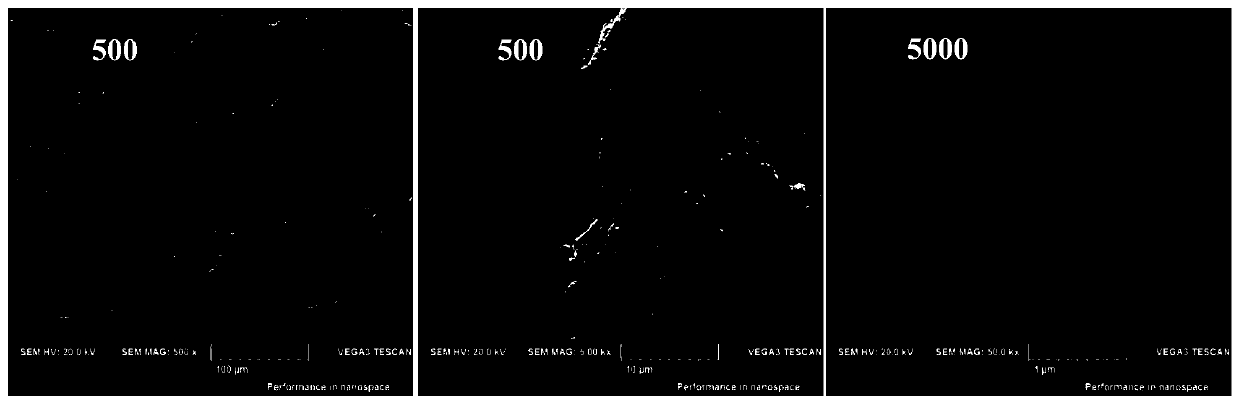

Embodiment 2

[0072] An embodiment of the porous heating film of the present invention, the structure of this embodiment is the same as that of the porous heating film described in Example 1: the base layer-heating layer-stable catalytic layer is TiN-Ti-Au.

[0073] The difference between the preparation methods of this example and Example 1 is only the porosity of the porous ceramic substrate, and the porosity of the porous ceramic substrate of this comparative example is 60%.

Embodiment 3

[0075] An embodiment of the porous heating film of the present invention, the structure of this embodiment is the same as that of the porous heating film described in Example 1: the base layer-heating layer-stable catalytic layer is TiN-Ti-Au.

[0076] The difference between the preparation methods of this example and Example 1 is only the porosity of the porous ceramic substrate, and the porosity of the porous ceramic substrate of this comparative example is 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com