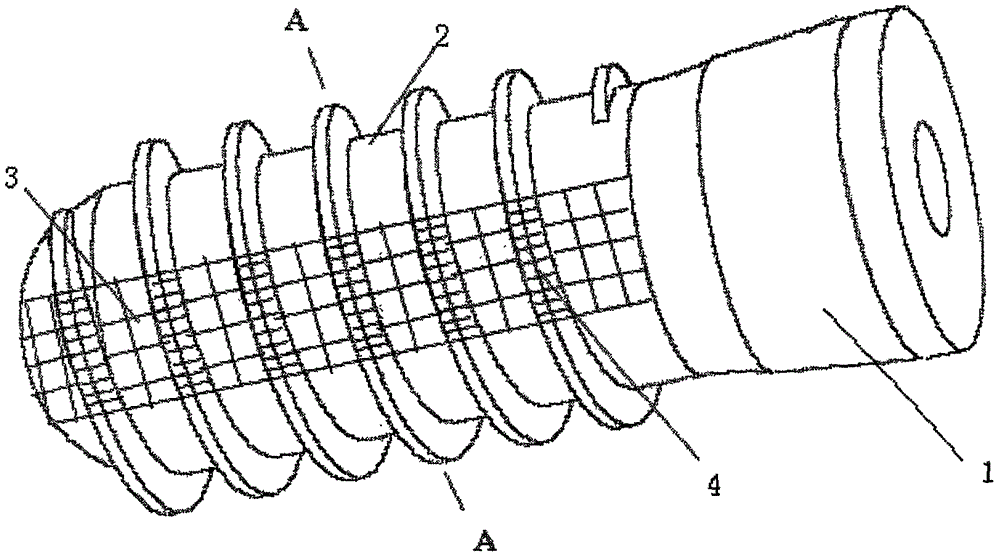

Segmented porous implant and design and manufacturing method thereof

A manufacturing method and implant technology, applied in the fields of implantology, medical science, dentistry, etc., can solve the problems of porous structure damage, failure to consider porous structure, implant fracture, etc., to ensure strength and use safety, facilitate ingrowth, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

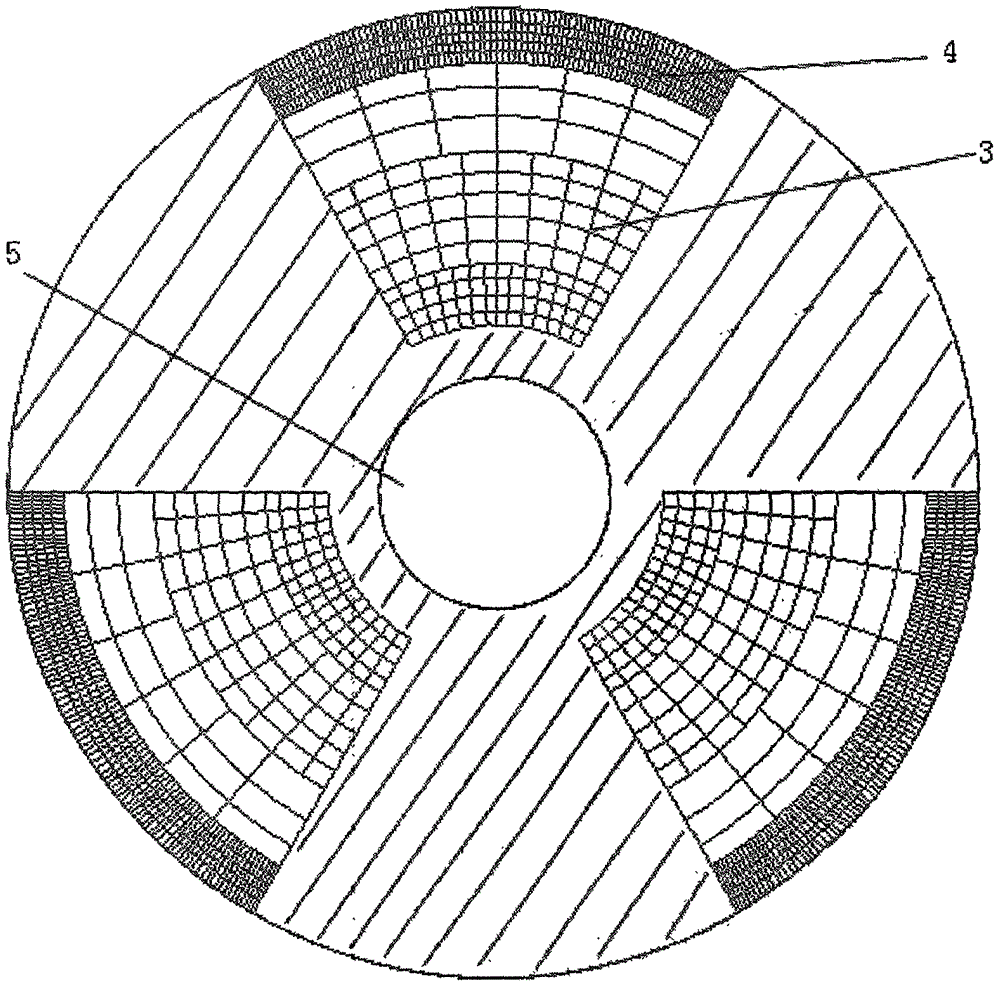

[0043] Embodiment 1: The body porous segment 3 and the threaded porous segment 4 of the segmented porous implant each occupy 3 sector-shaped areas. The body porous section 3 is divided into two parts radially from the inner surface to the outer surface, and the pore diameter gradient increases to 150 μm and 350 μm respectively. The pore diameter of the threaded porous section 4 is 60 μm, and the thickness of the threaded porous section 4 is 0.3 mm. The thickness of the porous section 3 is 0.5 mm, and the main body roughness of the body 2 is 4 μm.

Embodiment 2

[0044] Embodiment 2: The body porous segment 3 and the threaded porous segment 4 of the segmented porous implant each occupy 4 fan-shaped areas. The body porous section 3 is divided into three parts along the radial direction from the inside to the outside surface, the pore diameter gradient increases, respectively 150 μm, 200 μm and 250 μm, the pore diameter of the threaded porous section 4 is 100 μm, and the thickness of the threaded porous section 4 is 0.6 mm , the thickness of the body porous section 3 is 1 mm, and the main body roughness of the body 2 is 10 μm.

Embodiment 3

[0045] Embodiment 3: The body porous segment 3 and the threaded porous segment 4 of the segmented porous implant each occupy 5 sector-shaped areas. The body porous section 3 is divided into three parts along the radial direction from the inside to the outside surface, and the pore diameter gradient increases, respectively 150 μm, 200 μm and 400 μm, the pore diameter of the threaded porous section 4 is 140 μm, and the thickness of the threaded porous section 4 is 0.9mm , the thickness of the body porous section 3 is 1.3 mm, and the main body roughness of the body 2 is 20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com