Ternary composite photocatalytic nanometer reactor as well as preparation method and application thereof

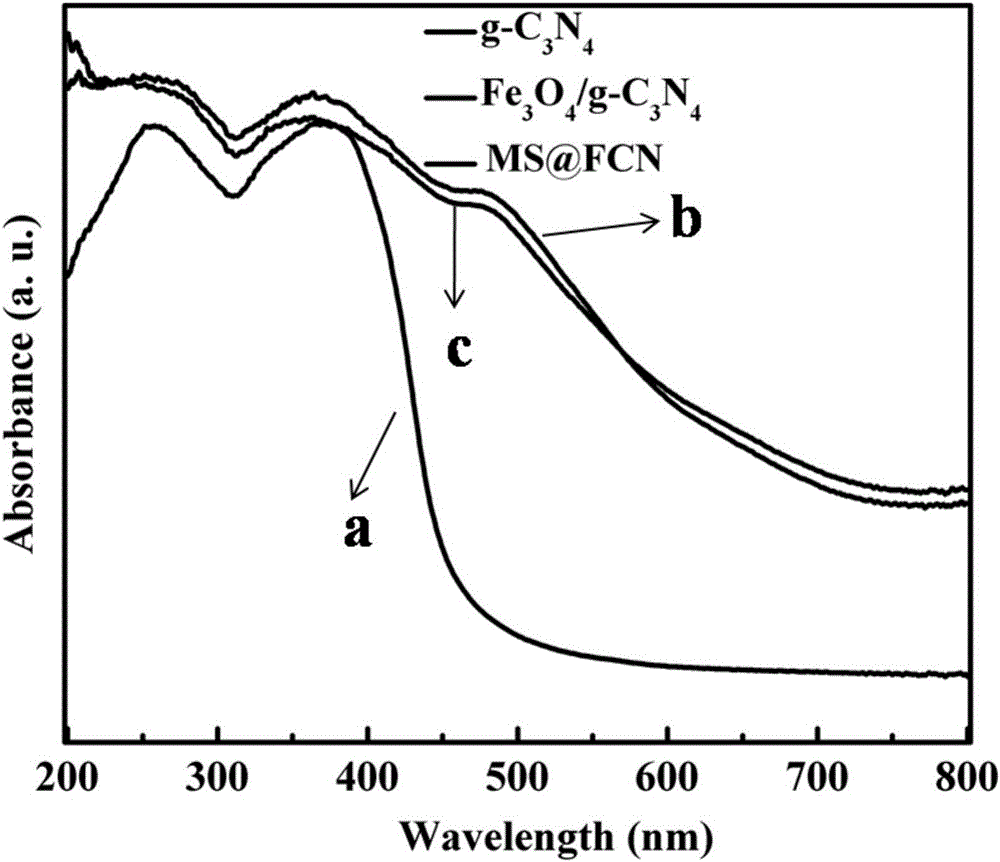

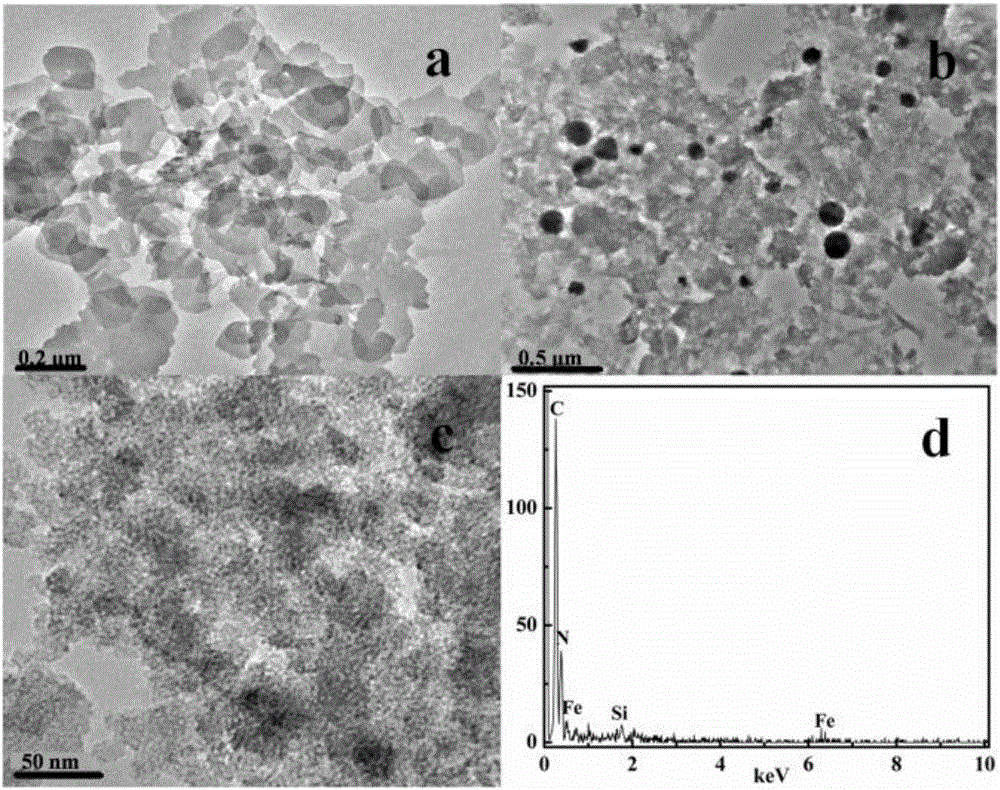

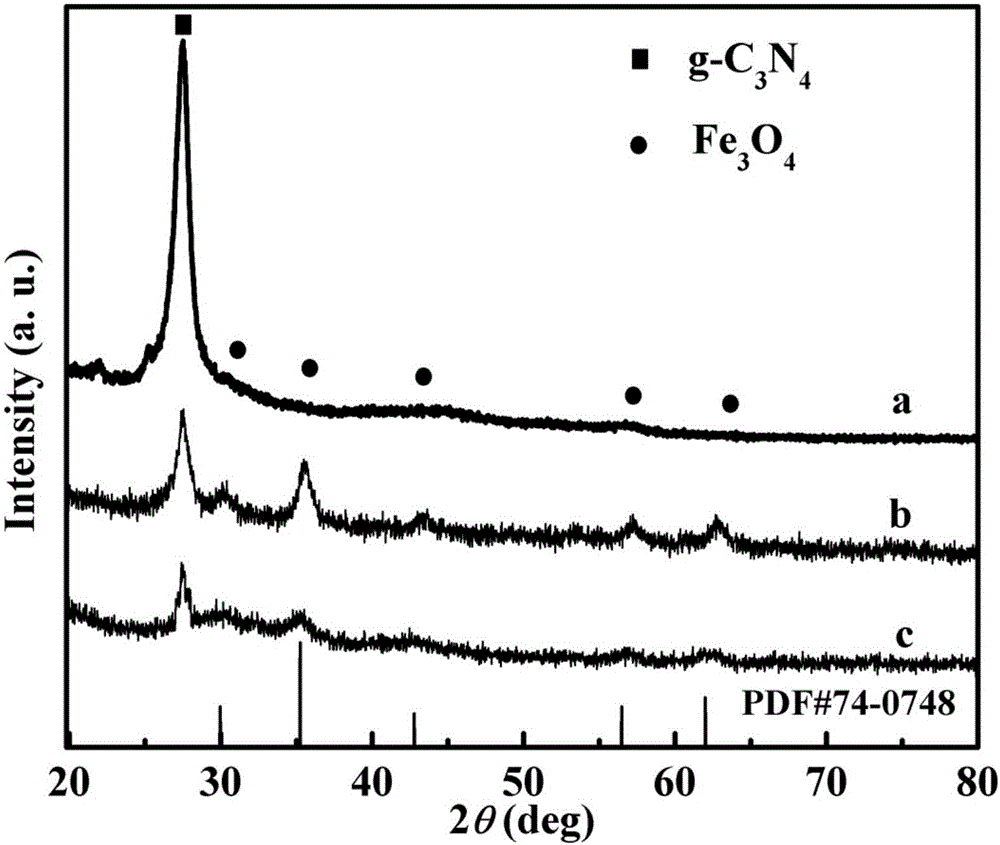

A nano-reactor and composite photocatalysis technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of composite material photocatalytic activity to be improved, easy fall-off performance of ferroferric oxide, high synthesis cost, etc. Achieve good stability and photocatalytic activity, improve photocatalytic effect, and good light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1. Preparation of g-C 3 N 4 Photocatalyst: Take 3g of purchased melamine and place it in a crucible, place it in a muffle furnace, and calcine it in an air atmosphere at 2.3°C min -1 Raise the temperature to 500°C at a constant temperature for 2 hours, continue to raise the temperature to 550°C at the same rate, and keep it at a constant temperature for 2 hours, cool naturally to room temperature and grind finely to obtain g-C 3 N 4 Photocatalyst, save for future use.

[0035] Step 2, prepare Fe 3 o 4 / g -C 3 N 4 : put g-C 3 N 4 Dispersed in ethylene glycol and sonicated to make g-C 3 N 4 suspension; the Fe(NO 3 ) 3 9H 2 O, PVP, PEG, and CH 3 COONa·3H 2 O dissolved in the above g-C respectively 3 N 4 in the suspension; continue to sonicate the above mixture until it is fully dissolved, then transfer the reaction mixture to a 50ml polytetrafluoroethylene reactor for constant temperature and heat reaction for a period of time; finally, the obtained p...

Embodiment 2

[0039] Step 1. Preparation of g-C 3 N 4 Photocatalyst: Take 6g of commercially available melamine and place it in a crucible, place it in a muffle furnace, and calcine it in an air atmosphere, raise the temperature to 500°C at a heating rate of 3°C / min, and keep it at a constant temperature for 2h. The heating rate continued to rise to 580 ° C, and kept at a constant temperature for 2 hours, cooled naturally to room temperature and ground to obtain g-C 3 N 4 Photocatalyst, save for future use.

[0040] Step 2, prepare Fe 3 o 4 / g -C 3 N 4 : put g-C 3 N 4 Dispersed in ethylene glycol and sonicated to make g-C 3 N 4 suspension; the Fe(NO 3 ) 3 9H 2 O, PVP, PEG, and CH 3 COONa·3H 2 O dissolved in the above g-C respectively 3 N 4 in the suspension; continue to sonicate the above mixture until it is fully dissolved, then transfer the reaction mixture to a 50ml polytetrafluoroethylene reactor for constant temperature and heat reaction for a period of time; finally, ...

Embodiment 3

[0044] Step 1. Preparation of g-C 3 N 4 Photocatalyst: Take 8g of commercially available melamine and place it in a crucible, place it in a muffle furnace, and calcine it in an air atmosphere, raise the temperature to 500°C at a heating rate of 4°C / min, and keep it at a constant temperature for 2h. The heating rate continued to rise to 600°C, and kept at a constant temperature for 2 hours, cooled naturally to room temperature and ground to obtain g-C 3 N 4 Photocatalyst, save for future use.

[0045] Step 2, prepare Fe 3 o 4 / g -C 3 N 4 : put g-C 3 N 4 Dispersed in ethylene glycol and sonicated to make g-C 3 N 4 suspension; the Fe(NO 3 ) 3 9H 2 O, PVP, PEG, and CH 3 COONa·3H 2 O dissolved in the above g-C respectively 3 N 4 in the suspension; continue to sonicate the above mixture until it is fully dissolved, then transfer the reaction mixture to a 50ml polytetrafluoroethylene reactor for constant temperature and heat reaction for a period of time; finally, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com