PE bottle inspecting and sorting system based on machine vision

A sorting system and machine vision technology, applied in the field of industrial robots and machine vision, can solve the problems of low work efficiency and low precision, and achieve the effects of high production efficiency, good accuracy and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

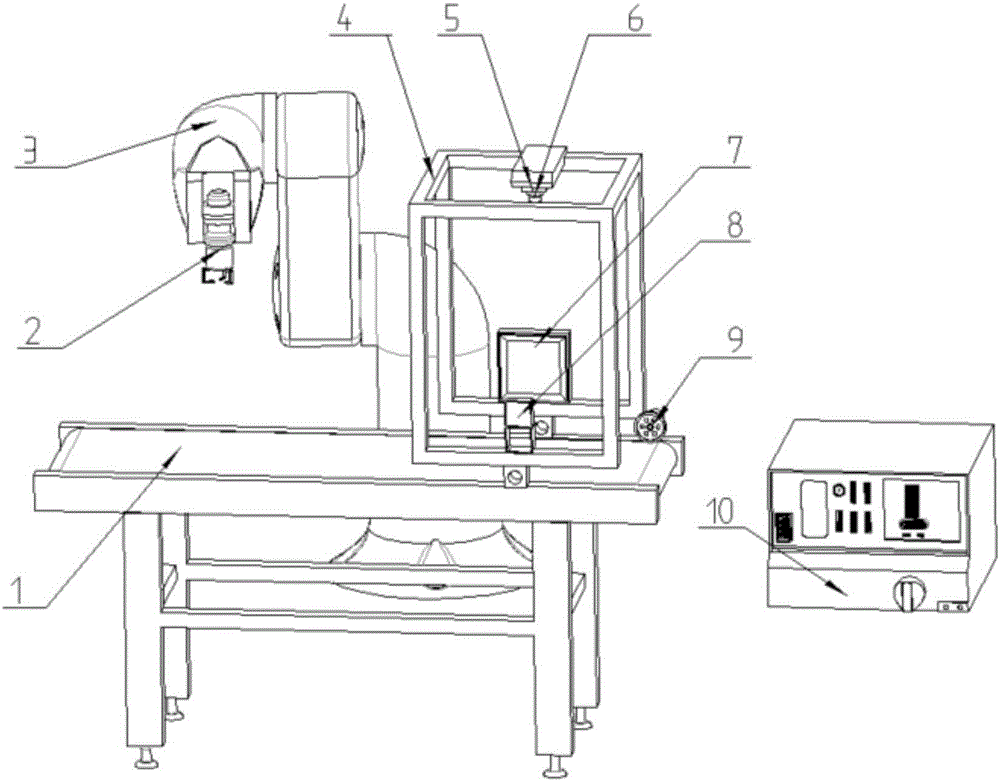

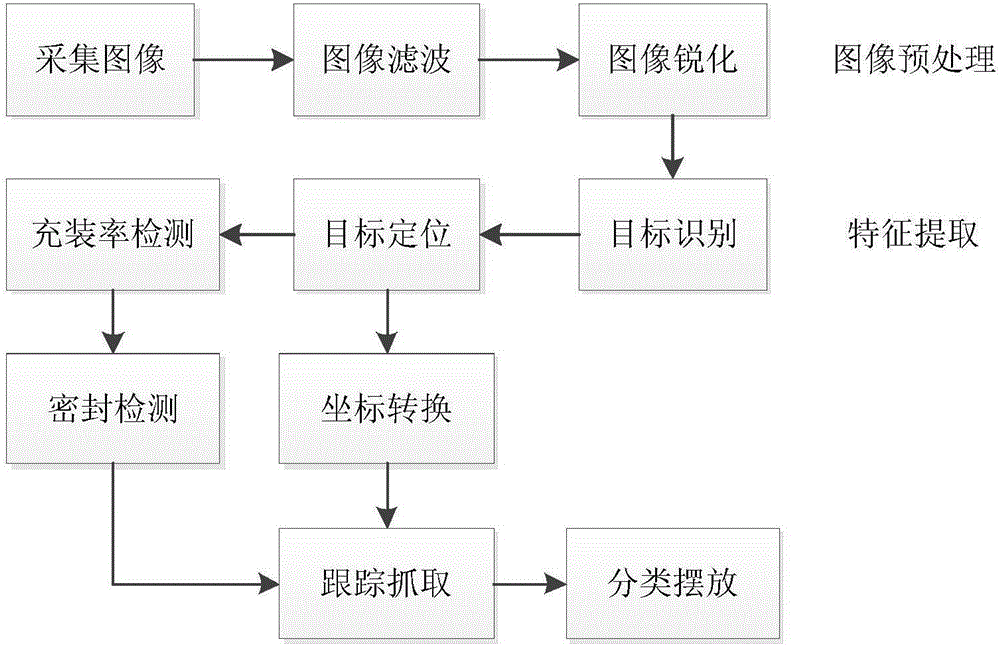

[0018] refer to figure 1 with figure 2 , an online PE bottle detection and sorting system based on machine vision, the system consists of four major units: transport transmission unit, visual detection unit, system control unit, sorting execution unit. The visual detection unit is arranged above the transport transfer unit, the visual detection unit is connected with the system control unit, and the system control unit is connected with the sorting execution unit.

[0019] The transportation unit includes a white conveyor belt 1 and a photoelectric encoder 9. The photoelectric encoder 9 is installed above the conveyor belt 1, and its function is to record and feed back the moving distance of the PE bottle on the conveyor belt in real time.

[0020] The visual detection unit includes a first industrial camera 6, a second industrial camera 8, a backlight 7, a ring lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com