Near-isothermal forging formation method for TC4 titanium alloy hollow shaft neck forged piece

A hollow journal and isothermal forging technology, which is applied in the field of warm forging and forming, can solve the problems of small deformation of the rod, uneven deformation, and affecting the quality of forgings, and achieve the effect of preventing temperature rise and increasing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0016] The main chemical element content (percentage by weight) of the TC4 alloy is: 5.5%-6.8% Al content, 3.5%-4.5% V content, 0.30% Fe content, 0.10% C content, 0.05% N content, The content of H is 0.015%, the content of O is 0.20%, and the balance is Ti.

[0017] The steps of this method are as follows:

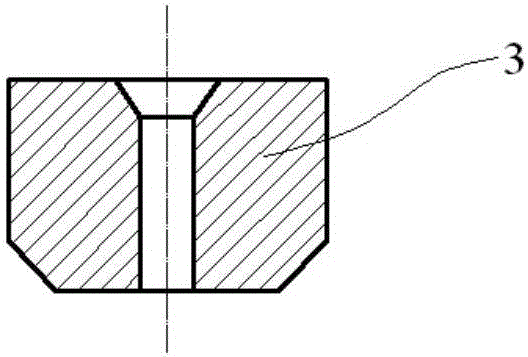

[0018] Heat the TC4 titanium alloy bar material cut according to the specifications in the forging heating furnace, first heat the bar material to 40°C below the phase transition point and keep it warm, and the holding time is calculated as 0.3min / mm-0.5min / mm; then raise the temperature to the phase transition point Heat preservation at 30°C above the change point, and the heat preservation time is calculated as 0.4min / mm~0.6min / mm; after heat preservation, the bar is subjected to upsetting, punching, pre-rolling, and chamfering to obtain a rectangular ring blank 3, such as figure 1 shown;

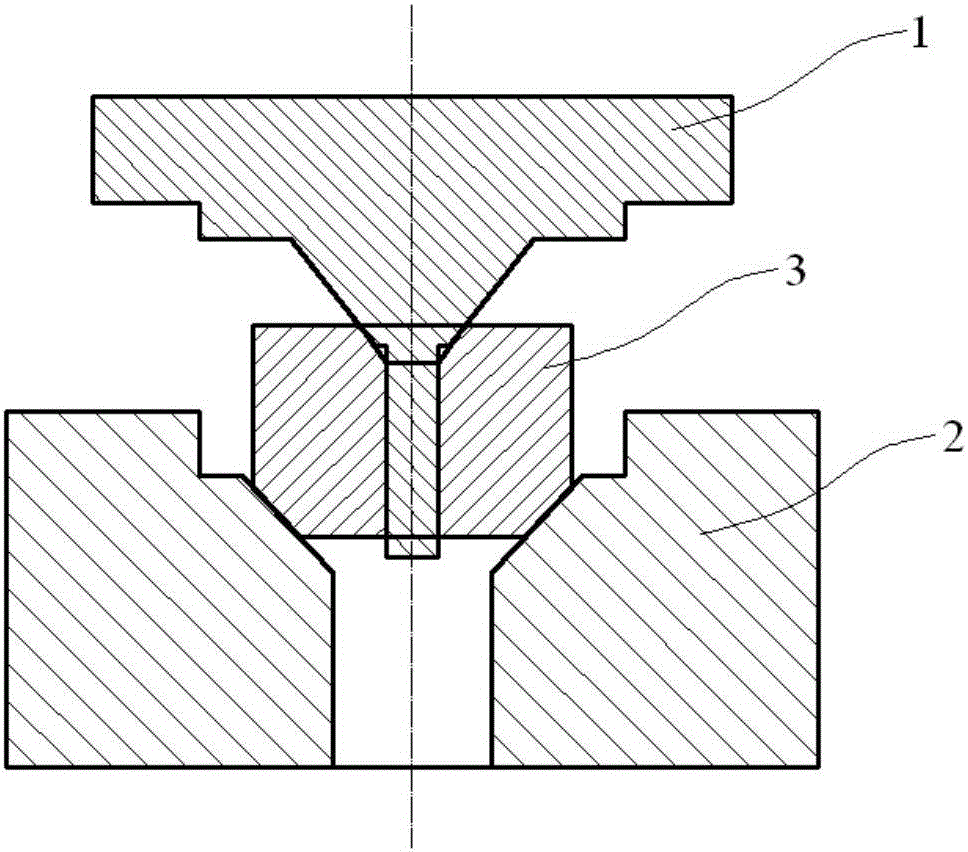

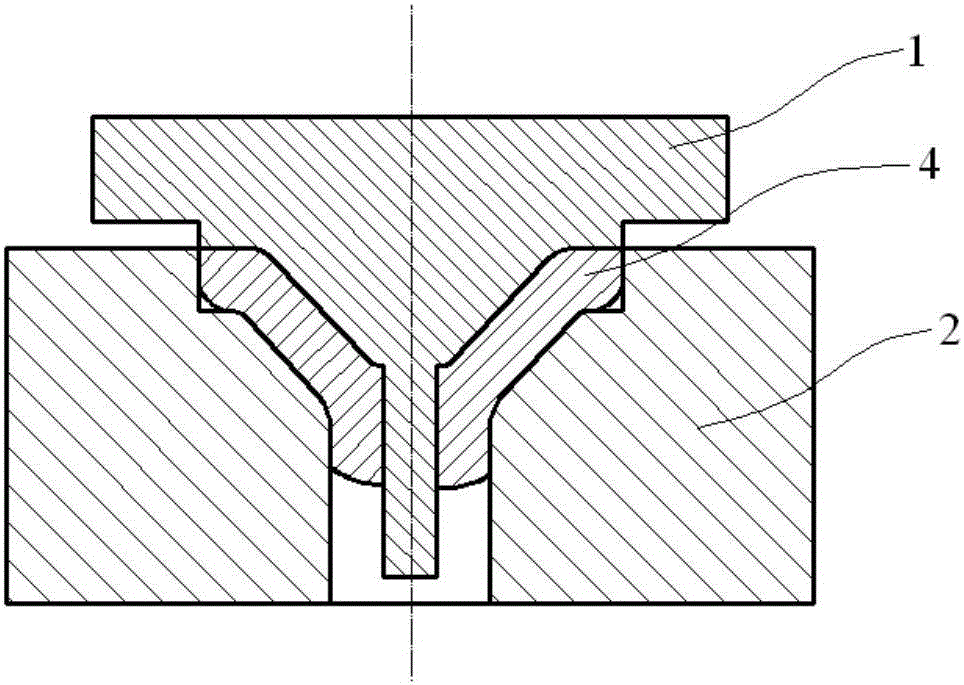

[0019] Such as figure 2 As shown, put the rectangular ring blank 3 into the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com