Wall climbing robot adsorbed on steel wall surface

A wall-climbing robot and wall surface technology, which is applied in the field of wall-climbing robots, can solve problems such as being unsuitable for crane inspection and use, and achieve good adsorption effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] 1. The overall structure of the wall-climbing robot for large port cranes

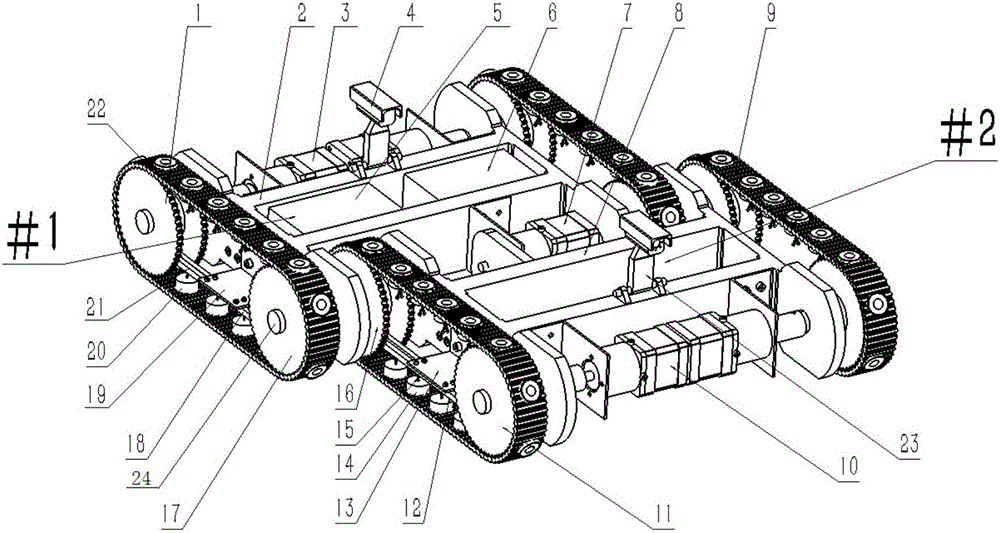

[0029] Such as figure 1 Shown is a schematic diagram of the overall mechanism of the wall-climbing robot.

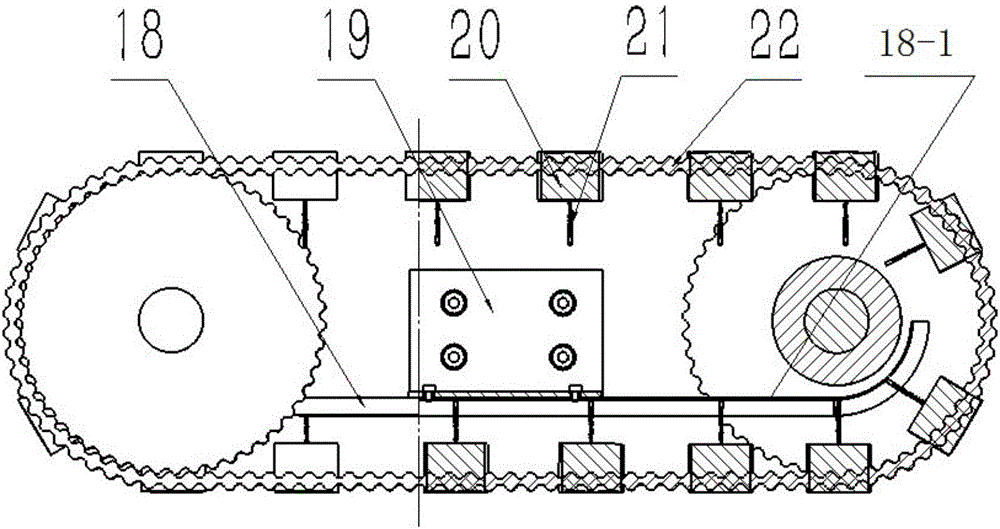

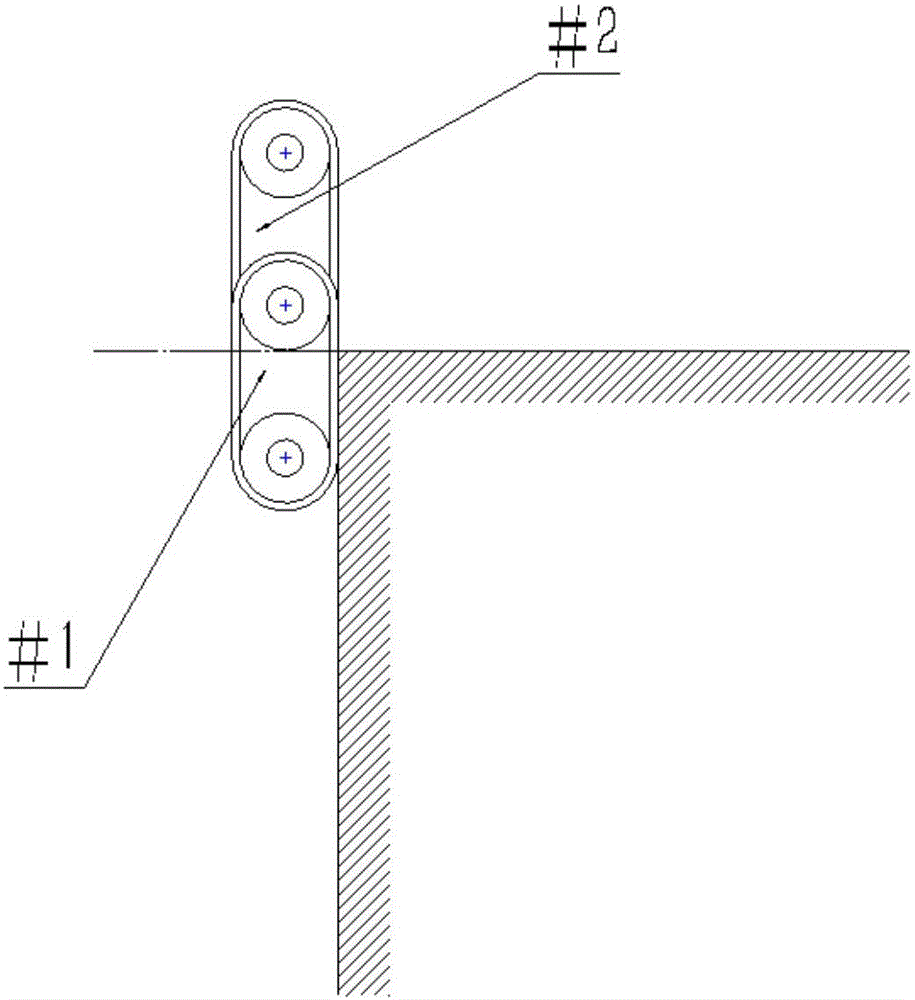

[0030]The wall-climbing robot consists of #1 crawler and #2 crawler. #1 crawler includes: driving wheel 1, frame 2, stepping motor 3, camera 4, controller 5, battery pack 6, driven wheels 17, electric brush chute 18, conductive plate 18-1, chute support frame 19, electromagnet 20, electric brush 21, crawler belt 22 and wall replacement motor 7. #2 crawler includes: frame 8, crawler belt 9, stepping motor 10, driving wheel 11, brush chute 12, conductive plate (not shown), chute support frame 13, electromagnet 14, electric brush 15 , driven wheel 16 and camera 23, hinge shaft 24.

[0031] 2. Adsorption and movement mode

[0032] The wall-climbing robot adopts the electromagnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com