Lifting device applied to paving of monorail crane for coal road heading machine

A technology of monorail crane and roadheader, applied in the direction of lifting device, hoisting device, lifting frame, etc., can solve the problems of difficult centering adjustment and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

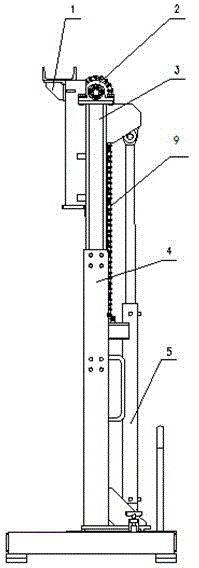

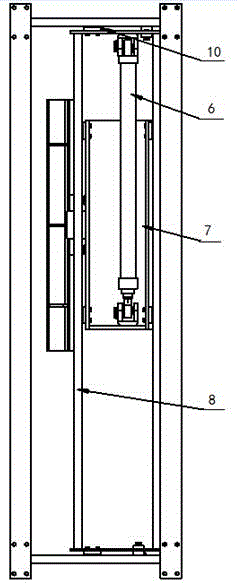

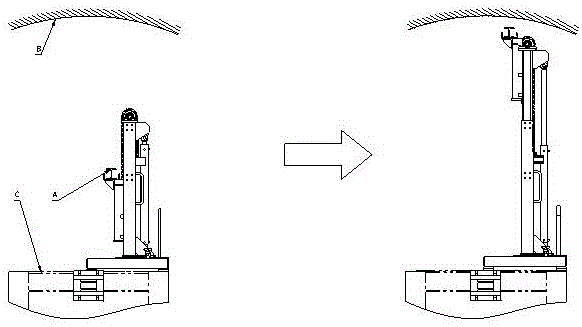

[0014] Referring to the accompanying drawings, a hoisting device applied to a monorail crane for laying a coal roadheader includes a bracket 1, a sprocket 2, a hoisting rail 3, a bracket 4, a hoisting cylinder 5, a traveling cylinder 6, a base 7, a traveling rail 8, Chain 9, combined bearing 10, the entire lifting device is located on the rear supporting trailer C of the roadheader in the roadway B, and the two sides of the bracket 1 use the combined bearing 6 to contact the inner vertical track of the lifting track 3, and the lifting track 3 The outer vertical track of the frame is connected with the combined bearing 10 on the bracket 4, the bracket 4 is in contact with the inner plane track of the running rail 8 through the combined bearing 10 installed at the bottom, and the running rail 8 is connected with the inner plane track of the base 7 through the combined bearing 10 , a lifting cylinder 5 is installed vertically on the support 4, one end is fixed on the support 4, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com