Special semi-steel radial tire for snow field and preparation method thereof

A radial tire and snow technology, which is applied in the field of semi-steel radial tires for snow and its preparation, can solve the problems of reduced grip, reduced tire friction, reduced handling and safety on slippery ice surfaces, etc., to achieve The effect of shortening the braking distance, shortening the braking distance, and improving the anti-thermal oxygen aging and anti-ozone aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

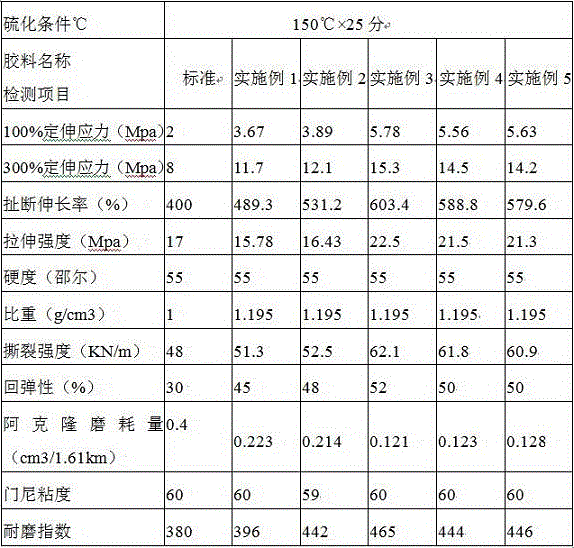

Examples

Embodiment 1

[0026] Embodiment 1, a special semi-steel radial tire for snow, including 30 parts by weight of natural rubber, 17 parts of butadiene rubber, 5 parts of styrene-butadiene rubber, 11 parts of white carbon black, 3 parts of silane coupling agent, 12 parts of aromatic oil, 1.2 parts of anti-aging agent, 1 part of microcrystalline wax, 8 parts of functional resin, 2 parts of white carbon black dispersant, 1 part of accelerator, 2 parts of tall oil, 1.3 parts of four-line oil, 1.5 parts of spindle oil , 0.8 parts of third-line oil, and 0.1 part of paraffin oil.

[0027] The functional resin includes an ion exchange and adsorption resin and a superabsorbent resin, and the weight ratio of the ion exchange and adsorption resin to the superabsorbent resin is 2.5:0.8.

[0028] The anti-aging agent includes 6PPD and TMQ, and the weight ratio of 6PPD and TMQ is 3.4:1.9.

[0029] The kinematic viscosity index of the aromatic oil is between 15-25.

[0030] The accelerator is NS and CZ, an...

Embodiment 2

[0039] Embodiment 2, a kind of special-purpose semi-steel radial tire for snow, by weight, comprises 43 parts of natural rubber, 23 parts of butadiene rubber, 9 parts of styrene-butadiene rubber, 20 parts of white carbon black, 5 parts of silane coupling agent, 20 parts of aromatic oil, 1.8 parts of anti-aging agent, 1.6 parts of microcrystalline wax, 14 parts of functional resin, 3.6 parts of white carbon black dispersant, 1.4 parts of accelerator, 2.6 parts of tall oil, 3.3 parts of four-line oil, 2.5 parts of spindle oil , 1.2 parts of third-line oil, and 0.13 parts of paraffin oil.

[0040] The functional resin includes an ion exchange and adsorption resin and a superabsorbent resin, and the weight ratio of the ion exchange and adsorption resin to the superabsorbent resin is 2.5:0.8.

[0041] The anti-aging agent includes 6PPD and TMQ, and the weight ratio of 6PPD and TMQ is 3.4:1.9.

[0042] The kinematic viscosity index of the aromatic oil is between 15-25.

[0043] Th...

Embodiment 3

[0052] Embodiment 3, a kind of special-purpose semi-steel radial tire for snow, by weight, comprises 36.5 parts of natural rubber, 20 parts of butadiene rubber, 7 parts of styrene-butadiene rubber, 15.5 parts of white carbon black, 4 parts of silane coupling agent, 16 parts of aromatic oil, 1.5 parts of anti-aging agent, 1.3 parts of microcrystalline wax, 11 parts of functional resin, 2.8 parts of white carbon black dispersant, 1.2 parts of accelerator, 2.3 parts of tall oil, 2.3 parts of four-line oil, 2 parts of spindle oil , 1 part of third line oil, 0.115 part of paraffin oil.

[0053] The functional resin includes an ion exchange and adsorption resin and a superabsorbent resin, and the weight ratio of the ion exchange and adsorption resin to the superabsorbent resin is 2.5:0.8.

[0054] The anti-aging agent includes 6PPD and TMQ, and the weight ratio of 6PPD and TMQ is 3.4:1.9.

[0055] The kinematic viscosity index of the aromatic oil is between 15-25.

[0056] The accel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com