A kind of multi-phase high dielectric constant composite material with isolation structure and its preparation method

A technology of high dielectric constant and composite materials, which is applied in the field of dielectric materials, can solve the problems of restricting practical applications, a large number of composite materials, and the reduction of mechanical properties, and achieve the effects of improving the interface, inhibiting agglomeration, and increasing the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

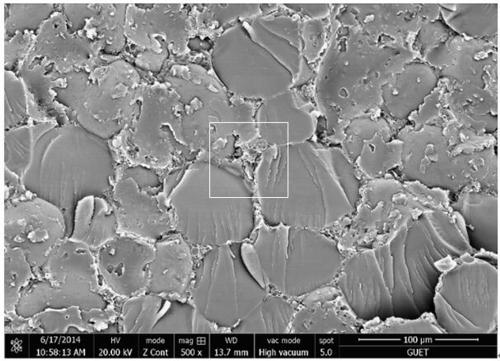

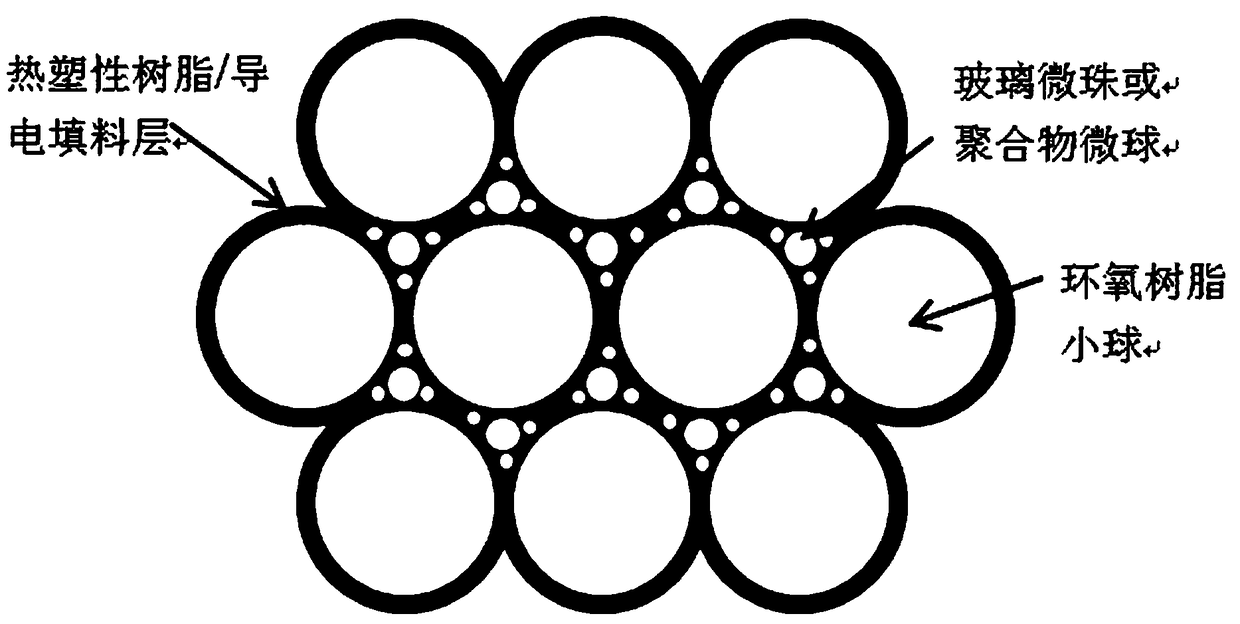

[0031] A method for preparing a high dielectric constant multi-component polymer-based composite material with an isolation structure, comprising the steps of:

[0032] (1) Dissolving 15 parts by mass of polyphenylene ether in 135 parts by mass of methylene chloride to obtain a polyphenylene ether solution;

[0033] (2) Then 1.5 parts by mass of PVP and 1.5 parts by mass of carbon black are uniformly mixed, and then mixed uniformly with the polyphenylene ether solution of step (1); finally, mixed uniformly with 5 parts by mass of glass beads to obtain a uniform mixture;

[0034] (3) The homogeneous mixture obtained in step (2) is further mixed with 100 parts by mass of epoxy resin, and finally the solvent is removed to obtain a further homogeneous mixture;

[0035] (4) Mix 100 parts by mass of diaminodiphenylsulfone DDS and 0.3 parts by mass of N,N-dimethylbenzylamine evenly, and add 85 parts by mass of this curing agent mixture to the mixture in step (3) Continue to mix well...

Embodiment 2

[0038] A method for preparing a high dielectric constant multi-component polymer-based composite material with an isolation structure, comprising the steps of:

[0039] (1) Dissolving 25 parts by mass of polyetherimide in 225 parts by mass of methylene chloride to obtain a polyetherimide solution;

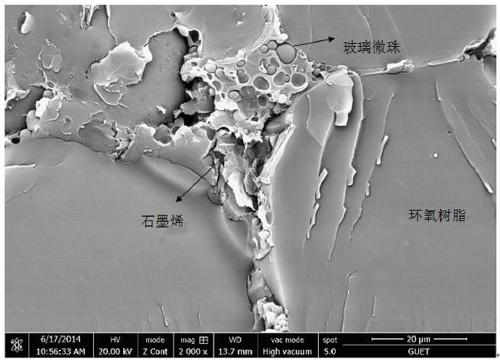

[0040] (2) Then mix 1 mass part of PVP and 1 mass part of graphene uniformly, then mix uniformly with the polyetherimide solution of step (1); finally mix uniformly with 7.5 mass parts of glass microspheres to obtain a uniform mixture;

[0041] (3) The homogeneous mixture obtained in step (2) is further mixed with 100 parts by mass of epoxy resin, and finally the solvent is removed to obtain a further homogeneous mixture;

[0042] (4) Mix 100 parts by mass of methyltetrahydrophthalic anhydride and 0.3 parts by mass of N,N-dimethylbenzylamine, and add 85 parts by mass of the curing agent mixture to step (3) Continue to mix well in the mixture;

[0043](5) The homogeneous mixture ...

Embodiment 3

[0045] A method for preparing a high dielectric constant multi-component polymer-based composite material with an isolation structure, comprising the steps of:

[0046] (1) Dissolving 40 parts by mass of polystyrene in 360 parts by mass of chloroform to obtain a polystyrene solution;

[0047] (2) Then 1.5 parts by mass of PVP and 1.5 parts by mass of carbon nanotubes are mixed evenly, and then mixed with the polystyrene solution of step (1); finally mixed with 10 parts by mass of glass beads to obtain a homogeneous mixture ;

[0048] (3) The homogeneous mixture obtained in step (2) is further mixed with 100 parts by mass of epoxy resin, and finally the solvent is removed to obtain a further homogeneous mixture;

[0049] (4) Mix 100 parts by mass of methylhexahydrophthalic anhydride and 0.3 parts by mass of N,N-dimethylbenzylamine, and add 85 parts by mass of the curing agent mixture to the step (2) Continue to mix well in the mixture;

[0050] (5) The homogeneous mixture ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com