UV crosslinked wide-color-gamut digital printing ink applicable to industrial piezoelectric nozzle and manufacturing method thereof

A digital printing and piezoelectric technology, which is applied in the field of UV cross-linked wide-color gamut digital printing ink, can solve the problems of easy aggregation of pigment dispersed particles, reduced surface energy, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

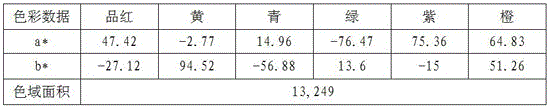

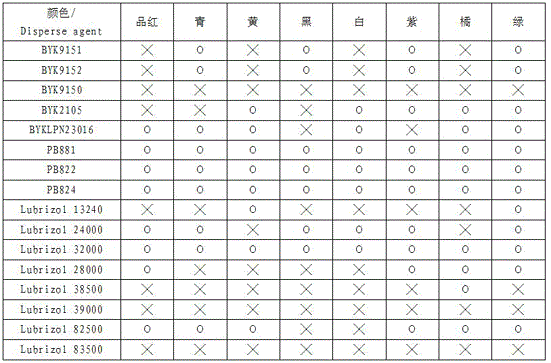

[0130] The process of UV ink is divided into two parts: the first part is to uniformly disperse the pigment in the reactive monomer solvent through grinding technology to become a color paste, and the second part is to make the dispersed color paste according to the various needs of the digital printing nozzle It is prepared by adding acrylic reactive monomer solvent, oligomer, mono- or multi-acrylic functional monomer, photoinitiator, and inhibitor. Through different formula ratios, inks with corresponding viscosities are developed, which are suitable for various nozzles. printing needs. At present, the UV ink color system used in the market is mainly C, M, Y, K, and W, and the color gamut is narrow. C.I.Pigment Blue 15:4 is usually used in the C market, and C.I.Pigment Blue 15:4 is usually used in the M market. C.I. Pigment Red 122, Y market usually uses C.I. Pigment Yellow 150, K market usually uses C.I. Pigment Black 7, and finally W market uses C.I. Pigment White 6. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com