Selective-self-adhesive liquid silicone rubber and preparation method thereof

A liquid silicone rubber, selective technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve product defects, can not be demolded and other problems, achieve easy operation, easy industrialization, Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

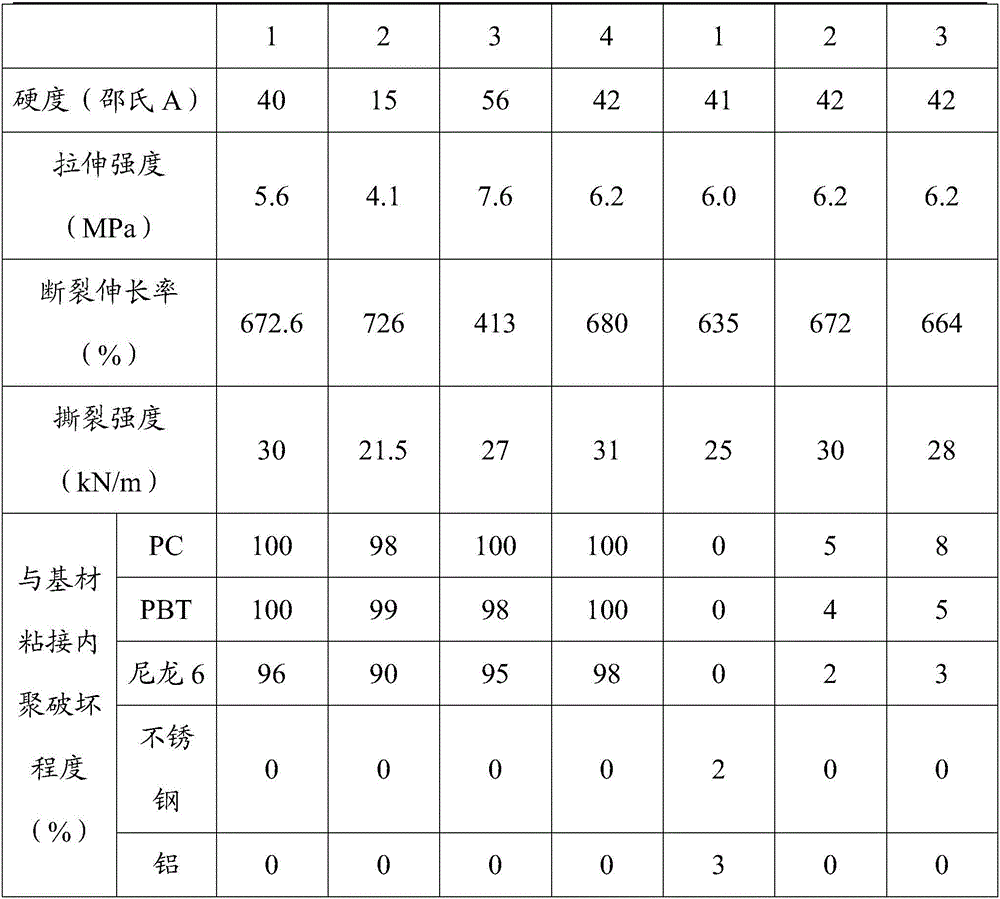

Embodiment 1

[0037] A kind of selective self-adhesive liquid silicone rubber of the present embodiment, its preparation method comprises the following steps:

[0038] (1) Refining of the base material: 48 parts by weight of α,ω-divinylpolydimethylsiloxane with a viscosity of 5800mPa·s, 38 parts by weight of 2 Hydrophobic fumed silica per gram, 2.5 parts by weight of vinyl hydroxy silicone oil (4.5 wt% vinyl content, 8 wt% hydroxyl content) were kneaded below 80°C for 1.5 hours. Then, 52 parts by weight of α,ω-divinyl polydimethylsiloxane with a viscosity of 5800 mPa·s was added to the kneaded product, and kneading was continued for 1 hour below 80°C. After uniform dispersion, the temperature was raised to Vacuum kneading at 160° C. for 3 hours with a vacuum degree of 0.09 MPa to prepare a base material.

[0039] (2) Preparation of component A: take 99.1 parts by weight of the above-mentioned base material, add 0.24 parts by weight of a catalyst with a platinum metal content of 5000 ppm, a...

Embodiment 2

[0043] A kind of selective self-adhesive liquid silicone rubber of the present embodiment, its preparation method comprises the following steps:

[0044] (1) Refining of the base material: 30 parts by weight of α,ω-divinylpolydimethylsiloxane with a viscosity of 30000mPa·s, 20 parts by weight of 2 Hydrophobic fumed silica / g, 0.56 parts by weight of vinyl hydroxy silicone oil (vinyl content 2 wt%, hydroxyl content 3.6 wt%) were kneaded at 80° C. or lower for 1 hour. Then, add 70 parts by weight of α,ω-divinylpolydimethylsiloxane with a viscosity of 30000mPa·s to the kneaded product, continue kneading at below 80°C for 0.5 hours, and after uniform dispersion, the temperature is raised to Vacuum kneading at 170° C. for 3.6 hours with a vacuum degree of 0.095 MPa to prepare a base material.

[0045] (2) Preparation of component A: take 94.6 parts by weight of the above-mentioned base material, add 3.6 parts by weight of a catalyst with a platinum metal content of 500 ppm, and ful...

Embodiment 3

[0049] A kind of selective self-adhesive liquid silicone rubber of the present embodiment, its preparation method comprises the following steps:

[0050] (1) Refining of the base material: 72 parts by weight of α,ω-divinylpolydimethylsiloxane with a viscosity of 20000mPa·s, 48 parts by weight of 2 Hydrophobic fumed silica / g, 8 parts by weight of vinyl hydroxy silicone oil (vinyl content is 2.5 wt%, hydroxyl content is 5.0 wt%) were kneaded below 80°C for 2 hours. Then, add 28 parts by weight of α,ω-divinylpolydimethylsiloxane with a viscosity of 30000mPa·s to the kneaded product, continue kneading at below 80°C for 0.8 hours, and after uniform dispersion, the temperature is raised to Vacuum kneading at 180° C. for 4.8 hours with a vacuum degree of 0.098 MPa to prepare a base material.

[0051] (2) Preparation of component A: Take 98 parts by weight of the above-mentioned base material, add 0.8 parts by weight of a catalyst with a platinum metal content of 2000 ppm, and stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com