Heat-resisting anti-wear lubricating oil and preparation method thereof

A lubricating oil and heat-resistant technology, which is applied in the field of lubricating oil, can solve problems such as insufficient anti-friction, insufficient function of lubricating oil, and inability of lubricating oil to exert its lubricating effect, and achieve good anti-wear performance, good lubricating effect, and good heat resistance The effect of anti-wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

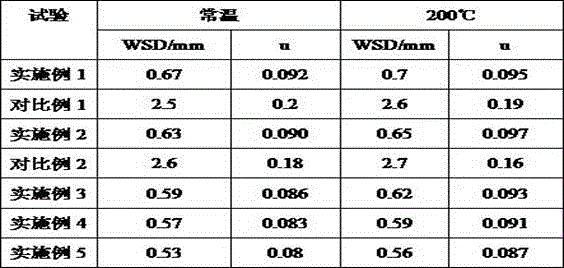

Examples

Embodiment 1

[0023] S1: Add 10 parts of allyl isothiocyanate, 6 parts of propylthiamine, 3 parts of 2-nitro-4-chlorophenol and 6 parts of fumaric acid resin to 50 parts of base oil, and raise the temperature to 70 ℃;

[0024] S2: Then add 10 parts of o-acetylsalicylic acid and 8 parts of diethylene glycol ether while stirring, raise the temperature to 100°C after the dropwise addition, and continue the reaction for 40 minutes to obtain the mixed solution A;

[0025] S3: Mix 4 parts of 3-thiophene formaldehyde, 9 parts of polyperfluoroethylene-propylene resin and 10 parts of 2-methyl-2-propanethiol, and ultrasonically vibrate for 5 minutes at a power of 1000W to obtain a mixed solution B;

[0026] S4: Add the mixed solution B in step S3 to the mixed solution A in step S2, adjust the reaction temperature to 90°C, and stir at a rate of 1000r / min for 1h; the heat-resistant and anti-wear lubricating oil can be obtained after the reaction is cooled.

Embodiment 2

[0032] S1: Add 14 parts of allyl isothiocyanate, 10 parts of propylthiouracil, 7 parts of 2-nitro-4-chlorophenol and 12 parts of fumaric acid resin to 70 parts of base oil, and raise the temperature to 80 ℃;

[0033] S2: Then add 20 parts of o-acetylsalicylic acid and 13 parts of diethylene glycol ethyl ether while stirring, raise the temperature to 120°C after the dropwise addition, and continue the reaction for 60 minutes to obtain the mixed solution A;

[0034] S3: Mix 8 parts of 3-thiophene formaldehyde, 13 parts of polyperfluoroethylene-propylene resin and 13 parts of 2-methyl-2-propanethiol, and ultrasonically vibrate at a power of 2000W for 10 minutes to obtain a mixed solution B;

[0035] S4: Add the mixed solution B in step S3 to the mixed solution A in step S2, adjust the reaction temperature to 100° C., and stir at a rate of 1200 r / min for 2 hours; the heat-resistant and anti-wear lubricating oil can be obtained after the reaction is cooled.

Embodiment 3

[0041] S1: Add 11 parts of allyl isothiocyanate, 7 parts of propylthiamine, 4 parts of 2-nitro-4-chlorophenol and 8 parts of fumaric acid resin to 55 parts of base oil, and raise the temperature to 70 ℃;

[0042] S2: Then add 14 parts of o-acetylsalicylic acid and 10 parts of diethylene glycol ethyl ether while stirring, raise the temperature to 100°C after the dropwise addition, and continue the reaction for 40 minutes to obtain the mixed solution A;

[0043] S3: Mix 4 parts of 3-thiophene formaldehyde, 9 parts of polyperfluoroethylene-propylene resin and 10 parts of 2-methyl-2-propanethiol, and ultrasonically vibrate for 5 minutes at a power of 1000W to obtain a mixed solution B;

[0044] S4: Add the mixed solution B in step S3 to the mixed solution A in step S2, adjust the reaction temperature to 90°C, and stir at a rate of 1000r / min for 1h; the heat-resistant and anti-wear lubricating oil can be obtained after the reaction is cooled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com