A vacuum evaporation machine and evaporation method thereof

An evaporation machine and vacuum technology, applied in the field of flat panel displays, can solve the problems of easy deformation of FMM storage and increased difficulty of FMM manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below.

[0033] The invention provides a vacuum evaporation machine capable of evaporating a material to be evaporated onto a substrate without a metal mask. Take the process of preparing three color blocks of color filters by using this vacuum evaporation machine as an example.

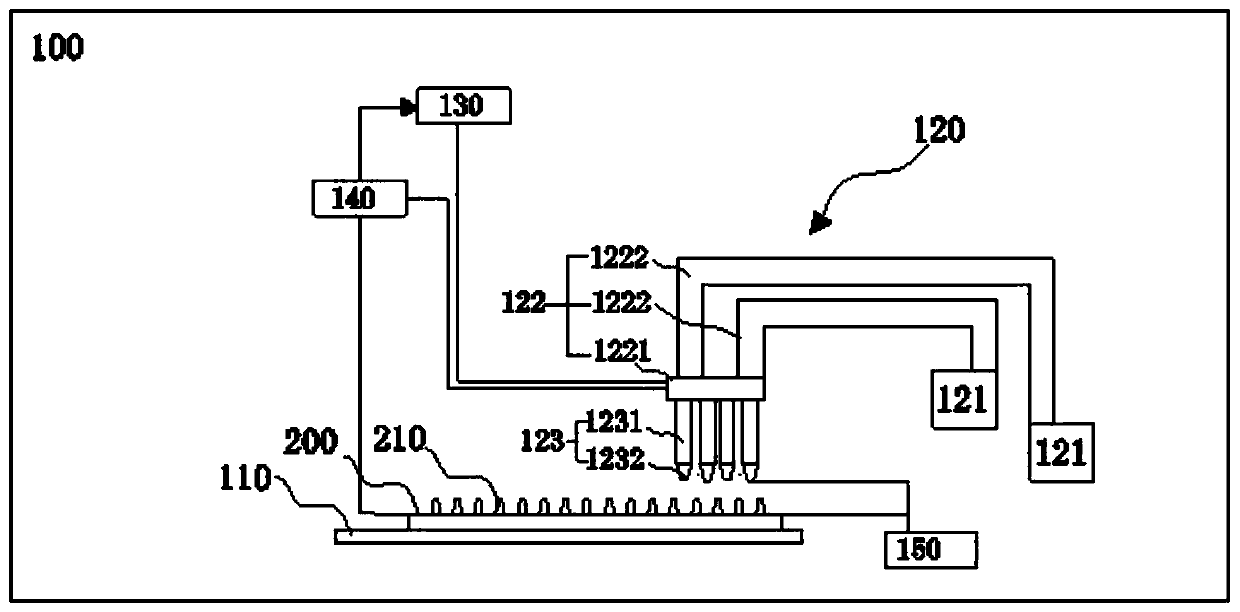

[0034] Such as figure 1 As shown, the vacuum evaporation machine of the present invention includes a console 100 on which a printing platform 110 , a printing device 120 , a driving device 130 , an automatic alignment device 140 , and a gap monitoring device 150 are arranged.

[0035] The printing platform 110 is installed on the console 100 , and the printing platform 110 is used for carrying the substrate 200 provided with the spacer 210 . Specifically, spacers 210 of a certain height are arranged around each sub-pixel to limit the diffusion of materials to regions other than the corresponding sub-pixel. Preferably, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com