Gas outlet end assembly of exhaust system of automobile engine and production technology thereof

A technology for automobile engines and exhaust systems, applied to engine components, machines/engines, exhaust devices, etc., can solve problems such as difficulty in ensuring position tolerances and size requirements, high production costs, and difficulty in ensuring the sealing performance of welding joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

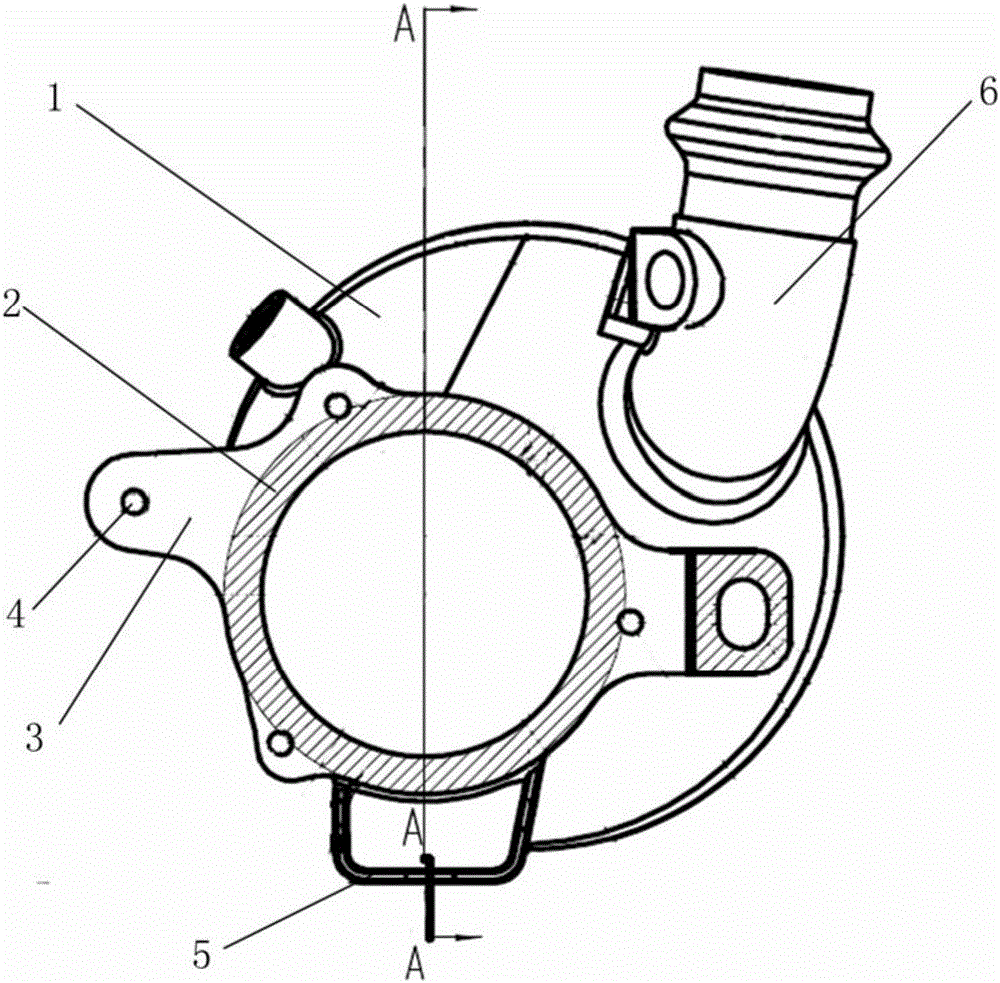

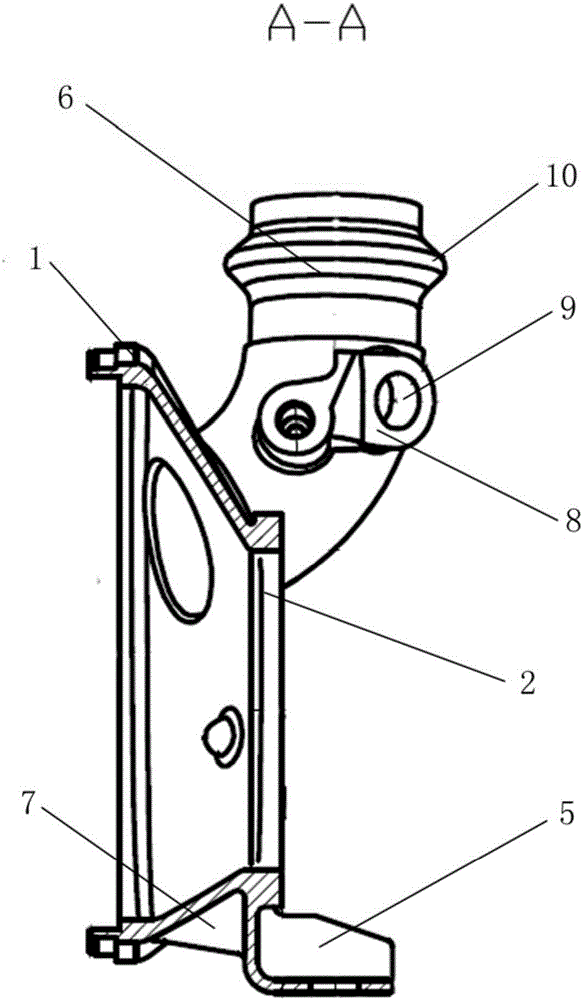

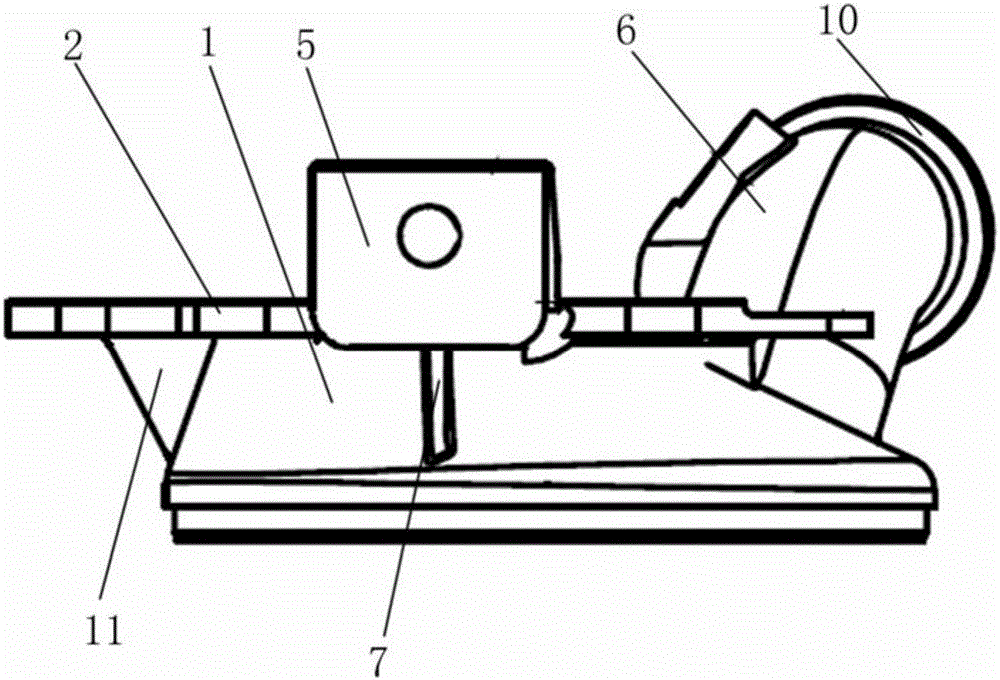

[0085] The automobile engine exhaust cone pipe of the present embodiment, as figure 1 , 2 As shown in and 3, it includes a tapered pipe body 1, an elbow 6 and a connecting flange 2. The tapered pipe body 1 is formed with a cavity from bottom to top, and the elbow 6 and the connecting flange 2 are respectively affixed to the top of the tapered pipe body 1. The elbow 6 and the connecting flange 2 are respectively connected with the cavity, and the tapered pipe body 1, the elbow 6 and the connecting flange 2 are made into one; the elbow 6 is provided with a connecting block 8, and the connecting block 8 is provided with a connecting groove 9. A protruding ring 10 is formed on the end of the elbow 6 away from the tapered pipe body 1 . The connecting flange 2 is fixed vertically upward to the limit block 5 . A first reinforcing rib 7 is formed between the limiting block 5 and the tapered tube body 1 . The connecting end of the connecting flange 2 is horizontally extended outwar...

Embodiment 2

[0131] The automobile engine exhaust cone of the present embodiment comprises a cone body 1, an elbow 6 and a connecting flange 2, the cone body 1 is formed with a cavity from bottom to top, and the elbow 6 and the connecting flange 2 are respectively connected to the cone The top of the body 1 is fixed, the elbow 6 and the connecting flange 2 are respectively connected with the cavity, and the tapered pipe body 1, the elbow 6 and the connecting flange 2 are made as one; the elbow 6 is provided with a connecting block 8, the connecting block 8 is provided with connecting groove 9. A protruding ring 10 is formed on the end of the elbow 6 away from the tapered pipe body 1 . The connecting flange 2 is fixed vertically upward to the limit block 5 . A first reinforcing rib 7 is formed between the limiting block 5 and the tapered tube body 1 . The connecting end of the connecting flange 2 is horizontally extended outwards with bosses 3 , there are four bosses 3 , and through holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com