Heat pump dryer

A technology for dryers and heat pumps, which is applied in the direction of dryers, drying, heat pumps, etc., can solve the problems of high energy consumption, unfavorable energy conservation and environmental protection, and achieve the effect of reducing heat pump power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

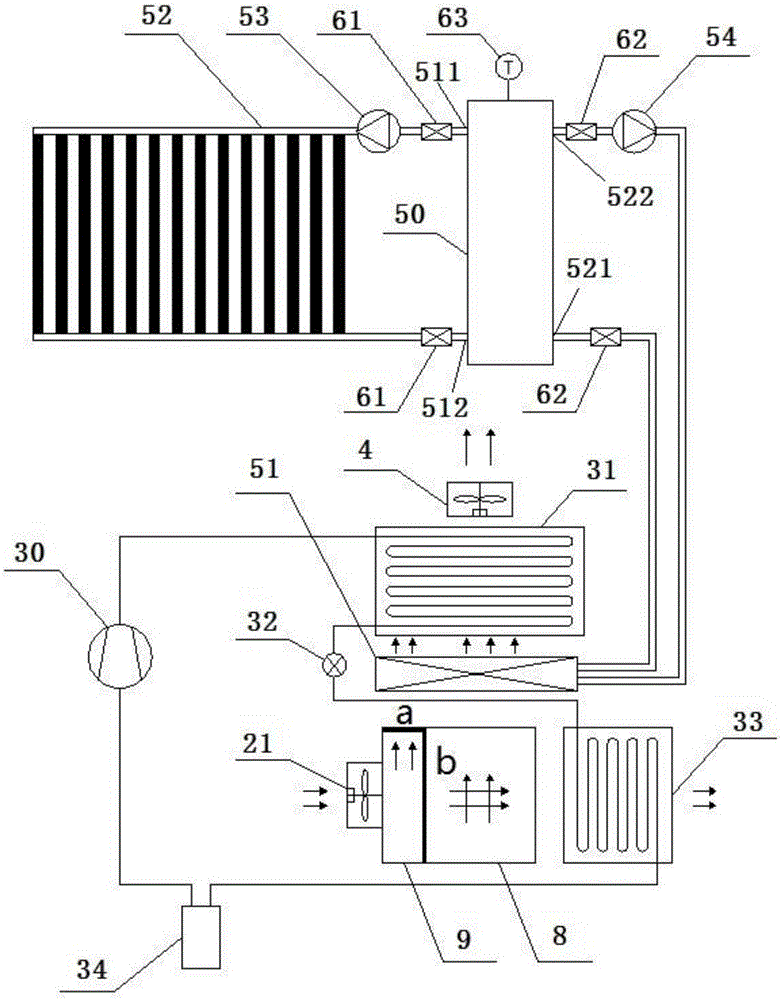

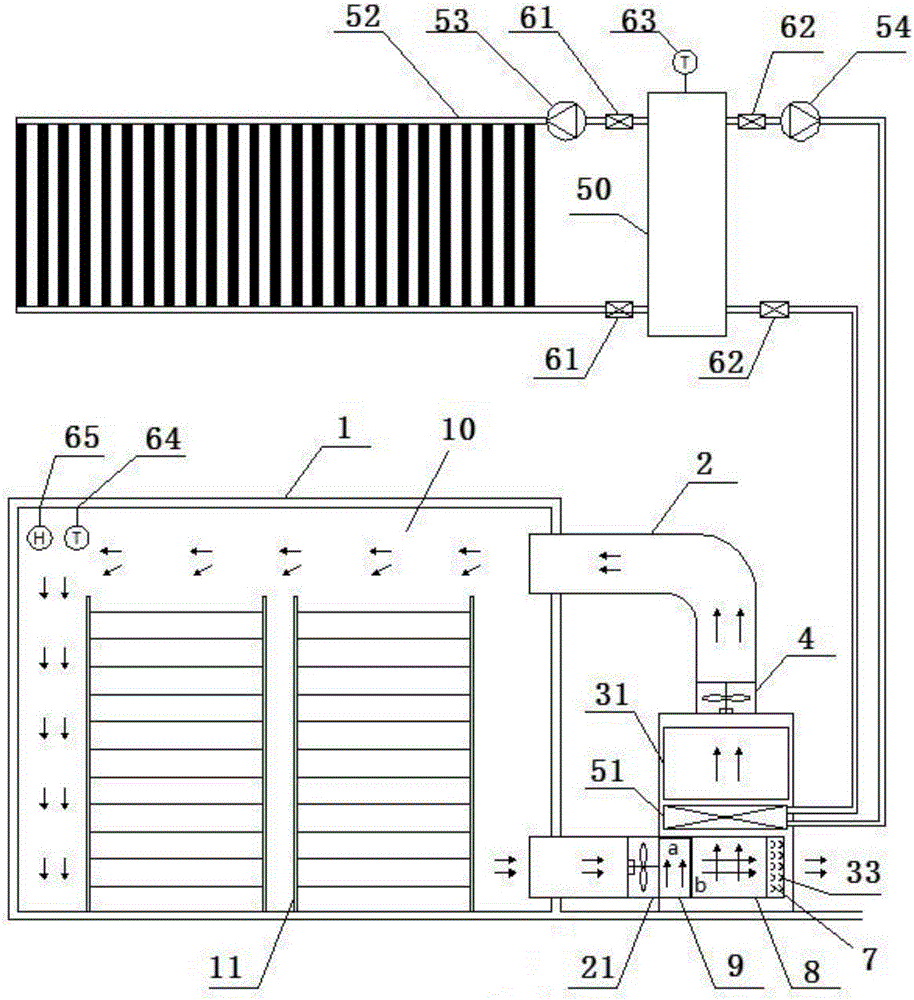

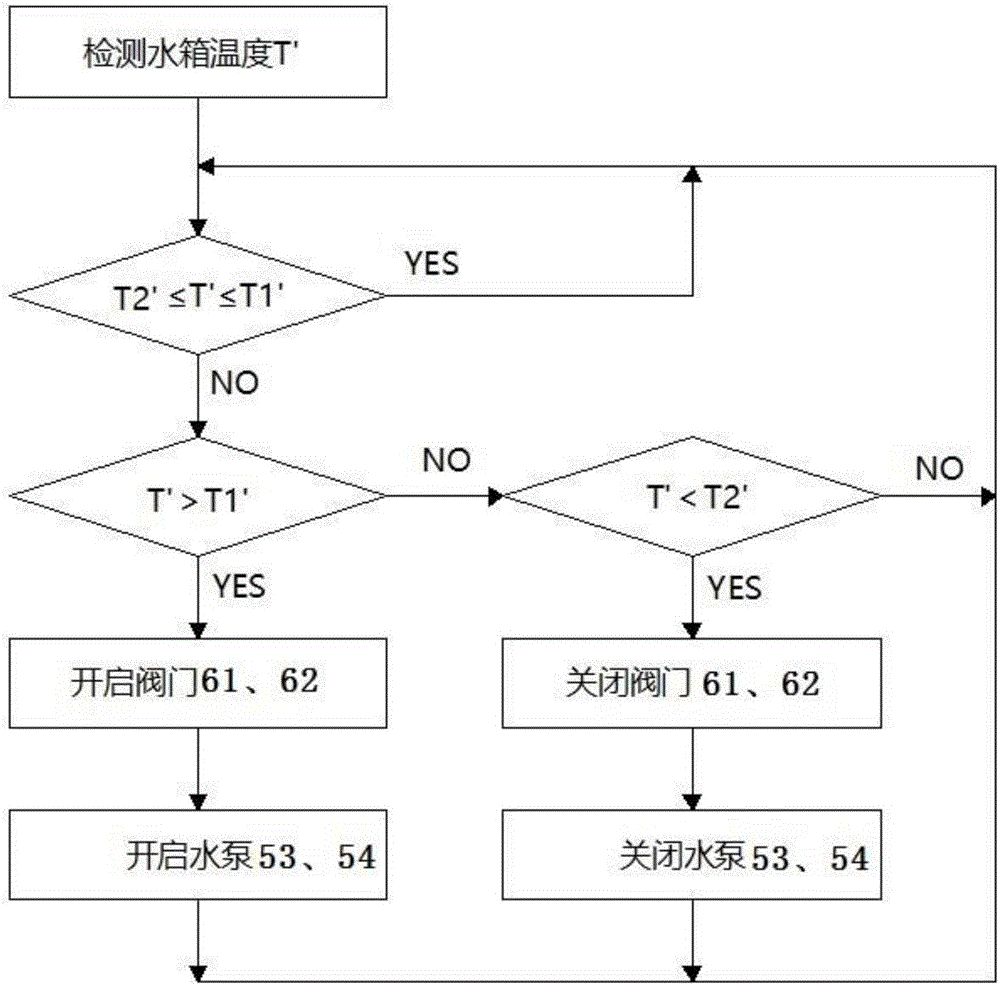

[0068] This embodiment provides a heat pump dryer, such as Figure 1-2 As shown, it includes: a drying room 1, which has a drying space 10, and an air inlet and an air exhaust port communicated with the drying space 10. The drying room 1 is provided with a drying room for placing articles to be dried. Shelves 11; air supply channel 2, communicated with the air inlet of the drying room 1; heat pump system, with a condenser 31, and the condenser 31 is used to heat the air entering the air supply channel 2; condensing fan 4 , installed inside the air supply channel 2, used to drive the air in the air supply channel 2 to flow to the air inlet of the drying room 1 after passing through the condenser 31; also includes: a solar heating system, with The heat dissipation coil 51 is installed upstream of the condenser 31 , so that the air can enter the drying room 1 after being heated by the heat dissipation coil 51 and the condenser 31 in sequence.

[0069] According to the technical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com