Testing method for coaxiality of flanges at two ends of pipeline valve

A detection method and coaxiality technology, applied in the detection field, can solve problems such as damage to the three-coordinate measuring machine platform, inability to guarantee coaxiality detection, unfavorable mass detection, etc., achieve good practicability and economy, and reduce labor Strength, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details.

[0017] Various embodiments according to the present invention will be described in detail below with reference to the accompanying drawings.

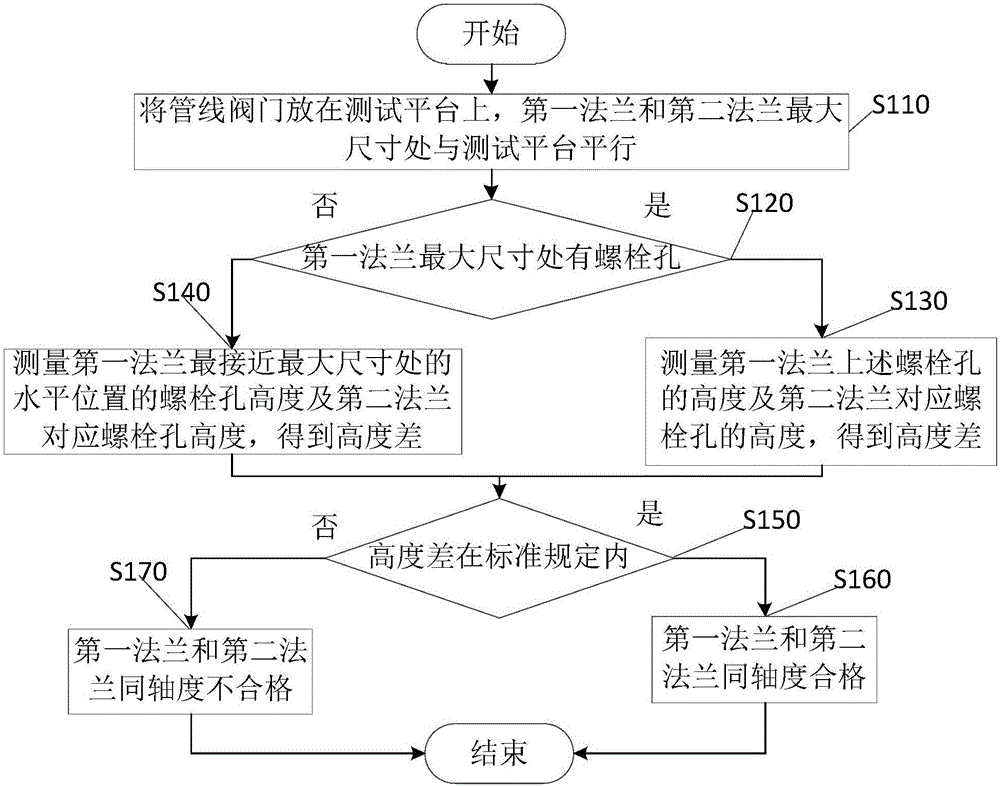

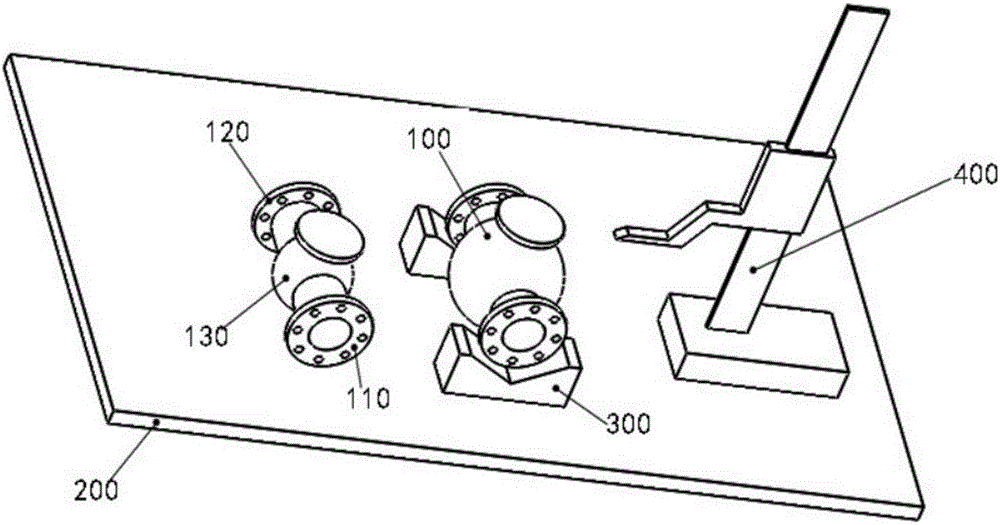

[0018] figure 1 It is a flow chart of the method for detecting the coaxiality of flanges at both ends of the pipeline valve of the present invention, figure 2 It is a schematic diagram of the method for detecting the coaxiality of flanges at both ends of the pipeline valve of the present invention, as figure 1 with 2 As shown, the method for detecting the coaxiality of flanges at both ends of the pipeline valve includes:

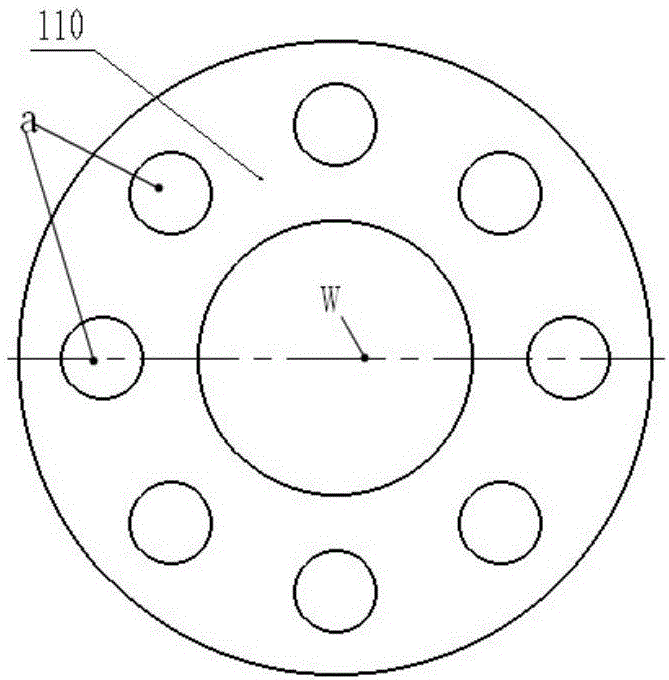

[0019] In step S110, the two ends of the pipeline valve 100 are symmetrically provided with a first flange 110 and a second flange 120,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com