Detection method of surface energy of glass

A glass surface and detection method technology, applied in surface tension analysis, surface/boundary effects, measuring devices, etc., can solve problems such as short validity period, high scientific research, product performance, and high storage environment requirements, so as to reduce detection cost and shorten detection Cycle, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

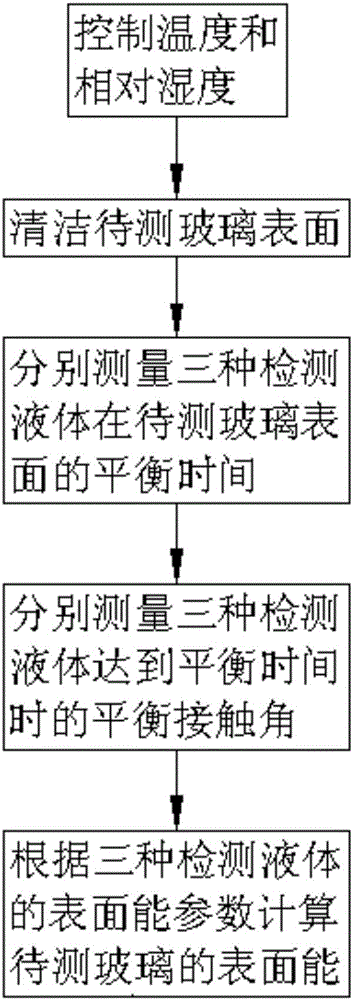

[0052] Select one or more combinations of detection liquids to calculate the surface energy of hydrophilic glass, such as "distilled water-formamide-diiodomethane" and "distilled water-glycerol-diiodomethane" two combinations, the specific steps are as follows:

[0053] Step 1: Control the temperature to be 18-22°C and the relative humidity to be 40-60%RH;

[0054] Step 2: Clean the surface of the glass to be tested, first wipe the surface of the glass to be tested 3 to 5 times with dust-free paper dipped in ethanol, and then wipe the surface of the glass to be tested 3 to 5 times with dust-free paper. The size of the measuring glass is 100mm×100mm;

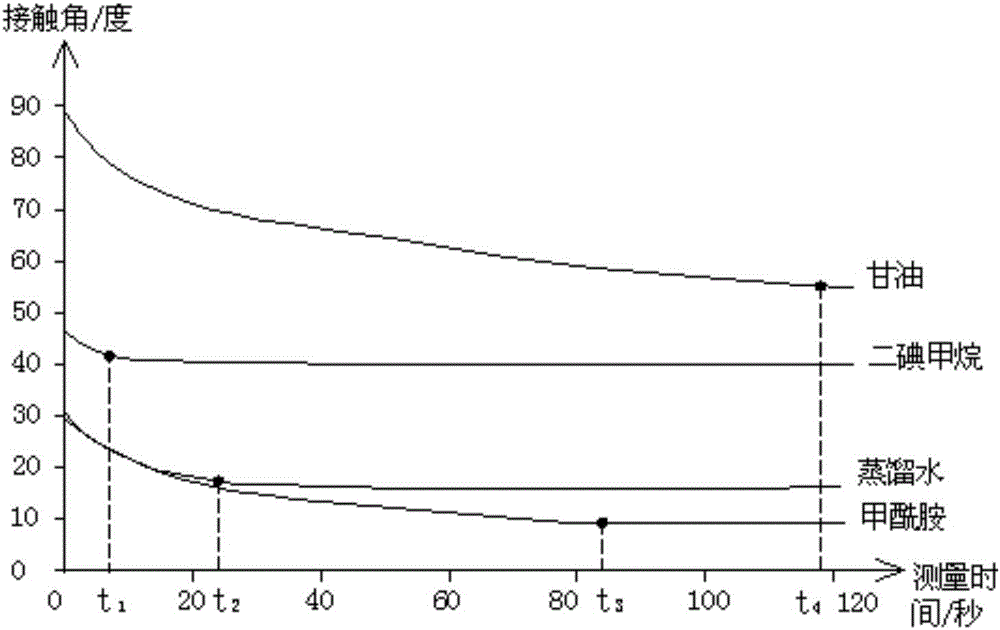

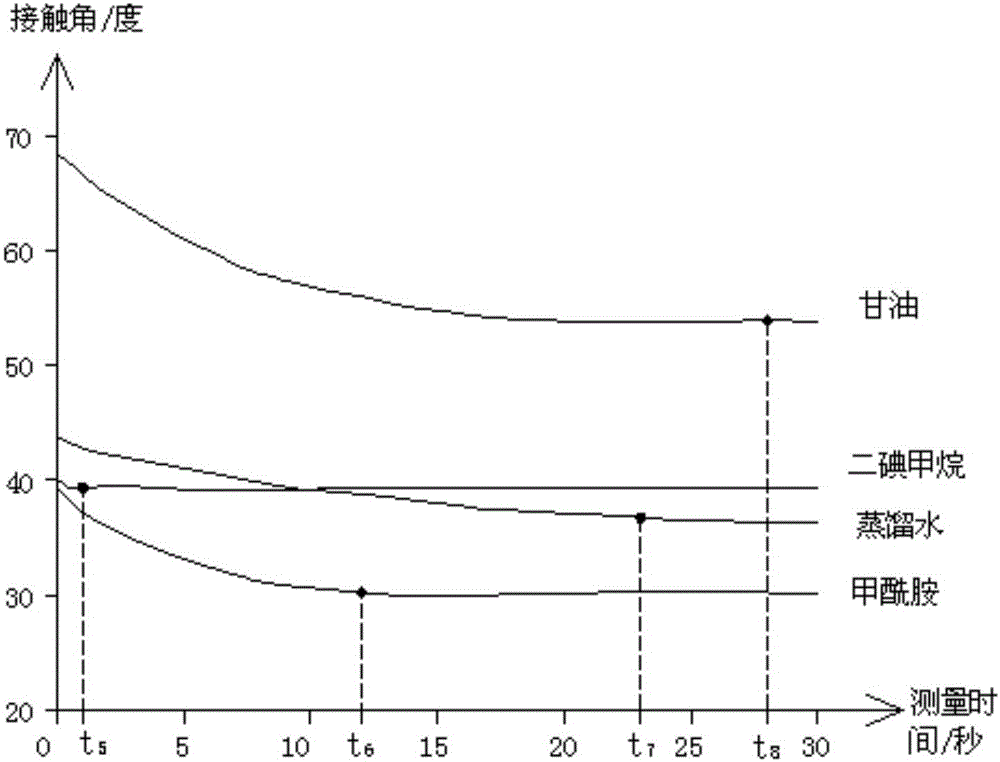

[0055] Step 3: Select "distilled water-formamide-diiodomethane" and "distilled water-glycerol-diiodomethane" as the detection liquid with known surface energy parameters, use a dropper with a diameter of 0.71mm, and use the hanging drop method to measure the detection liquid The surface energy of distilled water is 74.6mJ / m 2 ,Formamid...

Embodiment 2

[0066] Choose one or more combinations of detection liquids to calculate the surface energy of hydrophilic glass, such as "distilled water-formamide-diiodomethane" and "distilled water-glycerin-diiodomethane" two combinations, the specific steps are as follows:

[0067] Step 1: Control the temperature to be 18-22°C and the relative humidity to be 40-60%RH;

[0068] Step 2: Clean the surface of the glass to be tested, first wipe the surface of the glass to be tested with dust-free paper moistened with n-heptane for 3 to 5 times, and then wipe the surface of the glass to be tested with dust-free paper for 3 to 5 times. The size of the glass to be tested is 100mm×100mm;

[0069] Step 3: Select "distilled water-formamide-diiodomethane" and "distilled water-glycerol-diiodomethane" as the detection liquid with known surface energy parameters, use a dropper with a diameter of 0.71mm, and use the hanging drop method to measure the detection liquid The surface energy of distilled water is 74...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com