Gravity-based oil spraying distribution method and oil spraying separation apparatus

A technology of oil spraying and gravity, applied in cooling/ventilation/heating renovation, electrical components, electrical equipment structural parts, etc. The effect of promotion, reasonable structure and breakthrough cooling method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

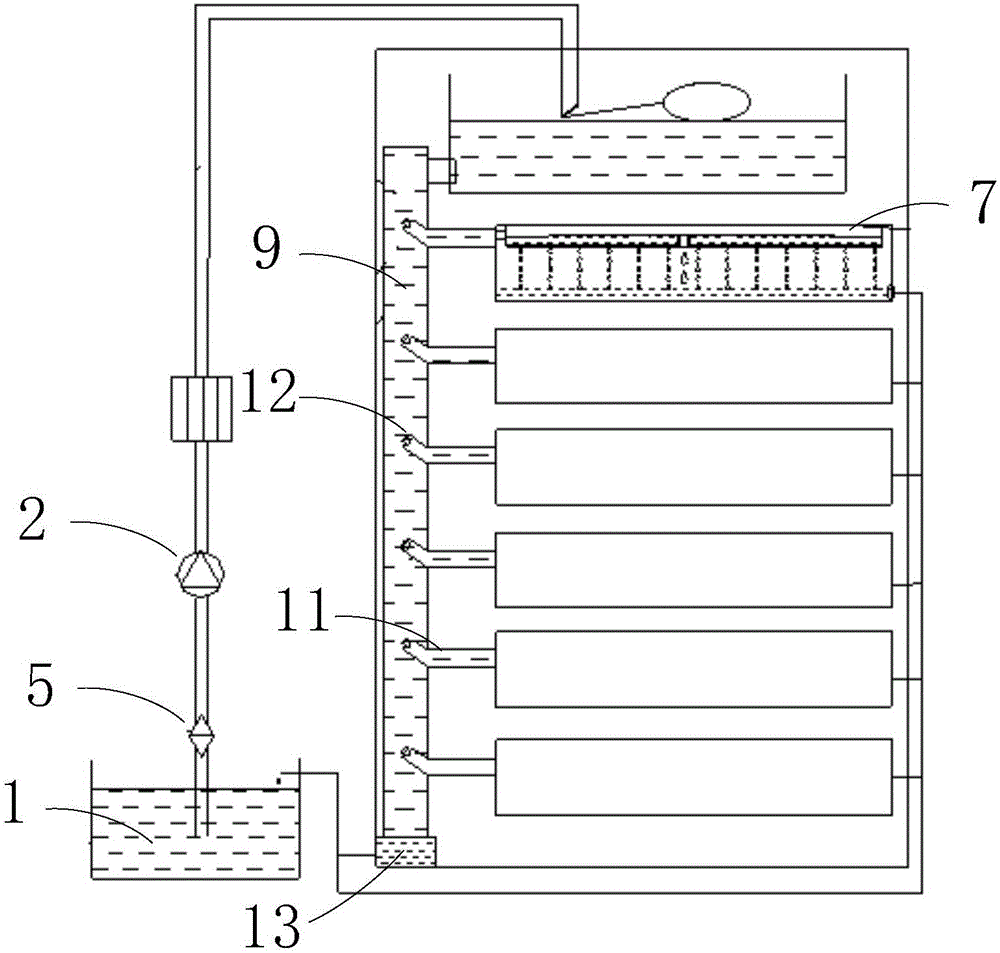

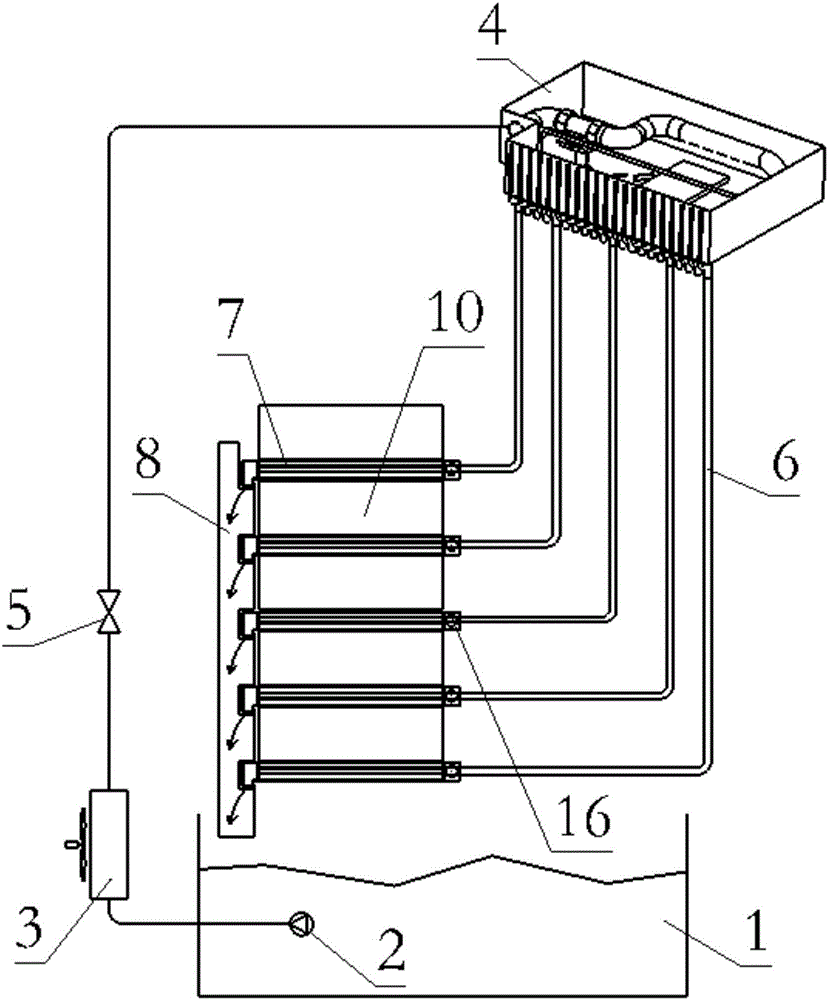

[0042] refer to Figure 1-16 As shown, a kind of oil separation device based on gravity, such as Figure 7-10 As shown, the oil separator 4 is included; the oil separator 4 includes a box body 41, at least one oil inlet port 43, and several oil separation units 44; the several oil separation units are installed on the box body 41; the oil separation unit 44 includes an oil separation and oil outlet 442; the cooling liquid oil enters the oil separator 4 from the oil separation and oil inlet 43, and from the oil separation and oil outlet 442 flows to each cooling branch.

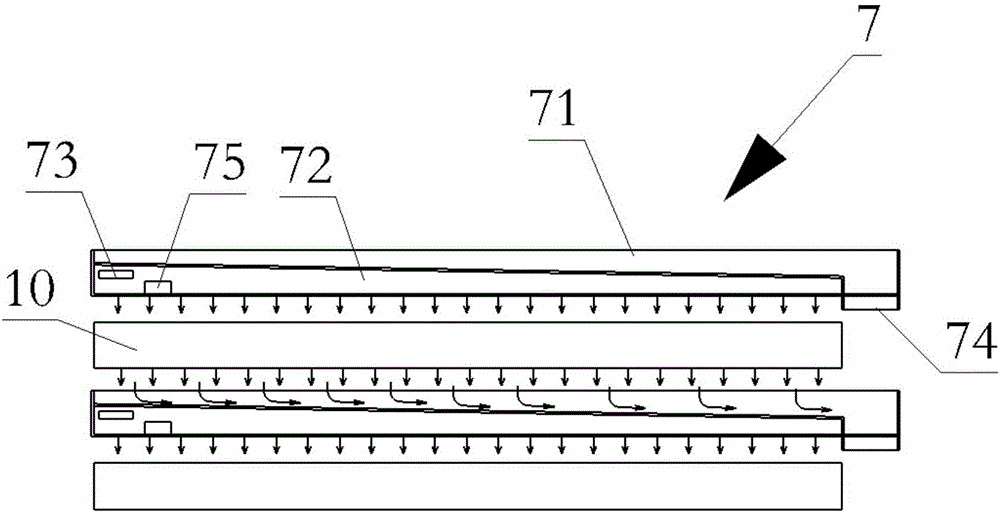

[0043] Preferably, as Figure 10-12 As shown, the oil separation unit 44 also includes a breather pipe 441, an oil volume regulator 443, and a diversion deflector 444; the oil volume regulator 443 is facing the oil distribution outlet 442, and the The oil volume re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com