Artificial automation device system for plant cultivation and manufacturing method for cylindrical body thereof

A plant and artificial technology, applied in botany equipment and methods, cultivation, fish farming, etc., can solve the problem of site and equipment nutrient solution, high sustainable cost of energy, difficulty in wide application of biotechnology for increasing production technology, failure to realize mechanical Automation and informatization and other issues, to achieve the effect of simple structure, low cost, and less manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

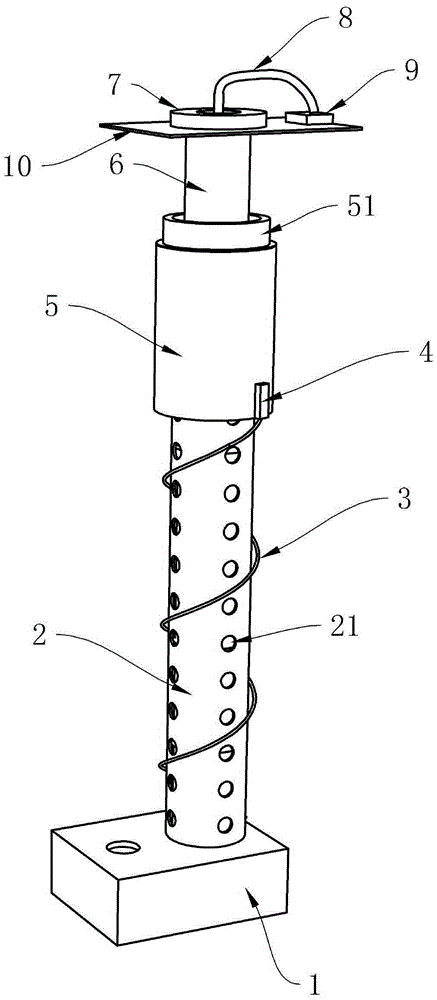

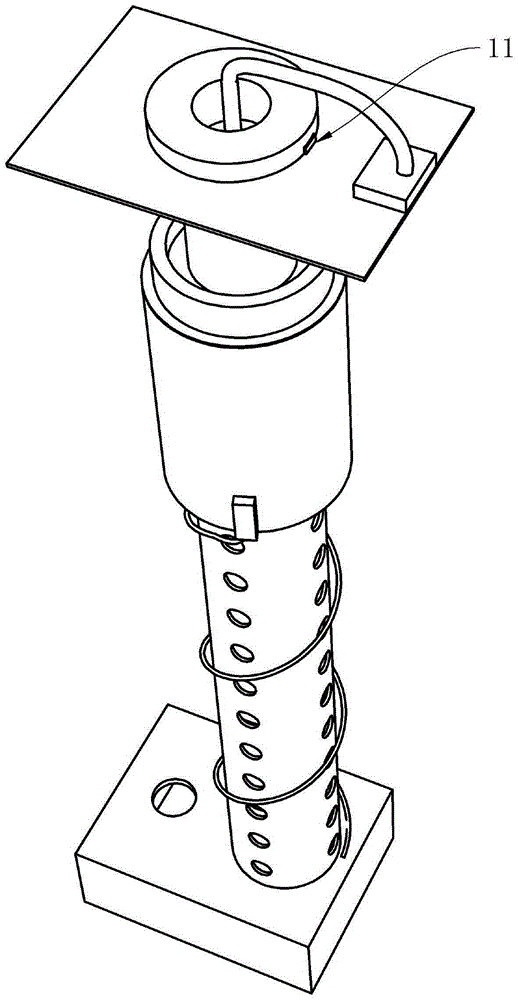

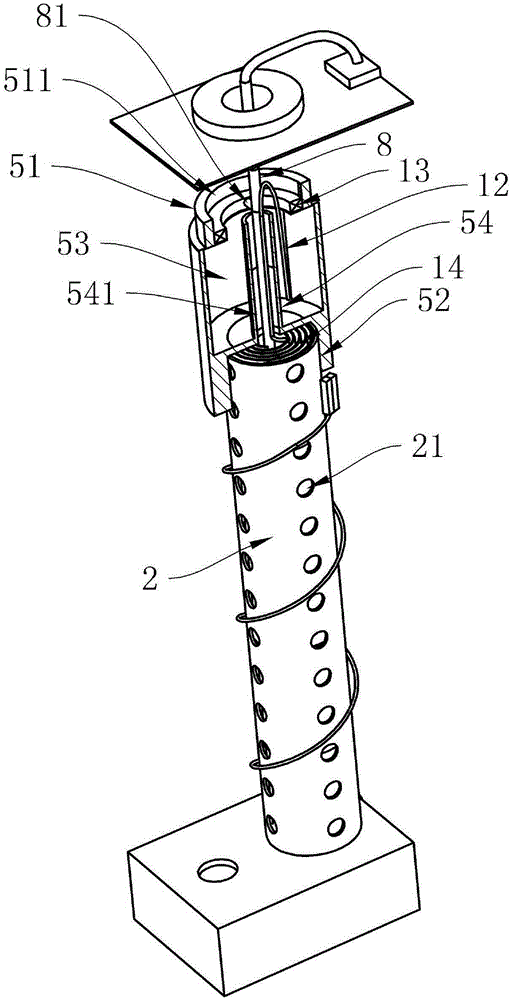

[0042] see Figure 1 to Figure 6 , a plant cultivation artificial automation facility system, comprising a water tank 1, a water pump 16 is housed in the water tank 1, the water output end of the water pump 16 is connected to the bottom end of the guide tube 8, and the guide tube 8 passes through The column body 2, the protection tube 54 of the slow-flow hydroponic chamber 5, the support tube 6 and the installation part 7 are internally connected to the atomizer 9, and the water pump 16 can be used to supply water to the atomizer during use, so that the atomizer 9 can generate water mist. This water mist can increase the aesthetics of the whole device on the one hand, and on the other hand, the leaves of the plants can be watered by the water mist. Of course, the water flow of the guide tube 8 can be cut off in the atomizer 16 to make the water flow in the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com