Continuous fiber bundle multi-layer co-extrusion head die

A continuous fiber and co-extrusion technology, applied in the field of continuous fiber bundle multi-layer co-extrusion dies, can solve the problems of easy separation of fibers and resins, long pipe production lines, and low service life of products, and achieve fiber modification The effect is remarkable, the process operation is simple, and the flow channel design is reasonable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

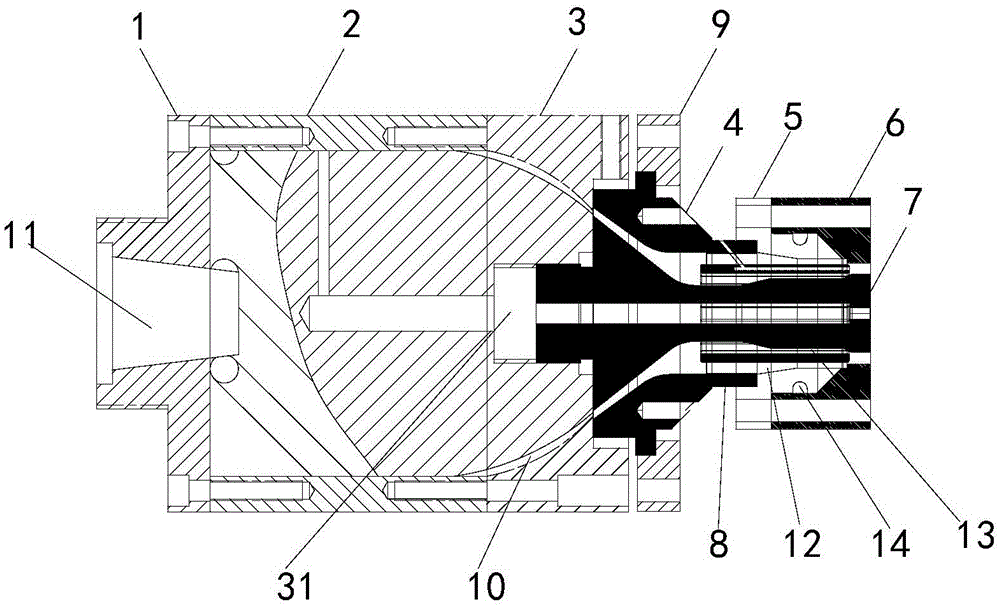

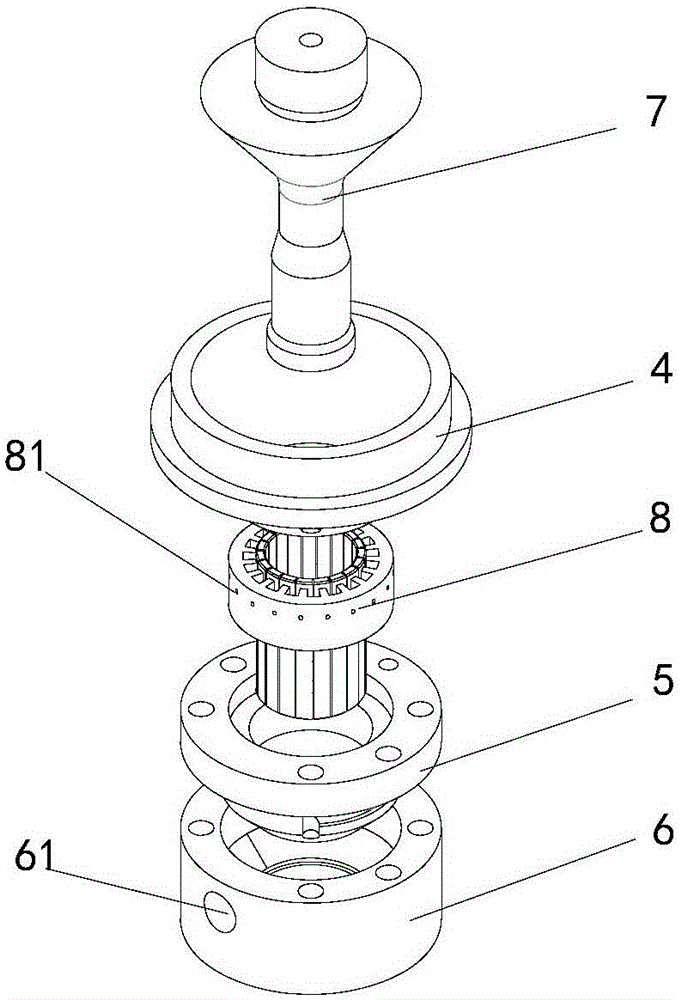

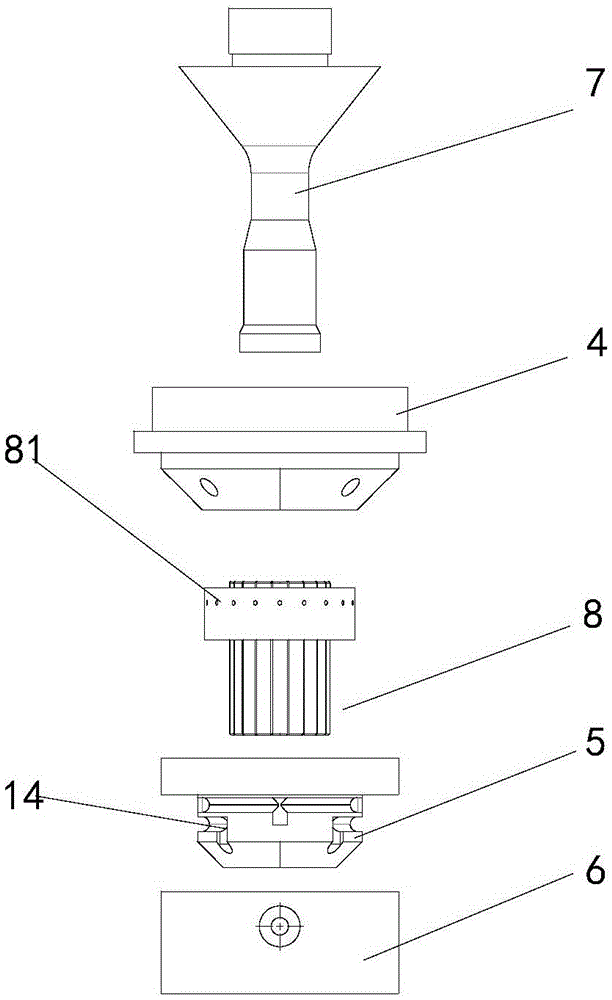

[0024] see figure 1 , with reference to figure 2 , image 3 , the continuous fiber bundle multi-layer co-extrusion head die of the present invention includes a composite die head formed by sequentially connecting the first die head 1, the second die head 2 and the third die head 2, and the first die head arranged in sequence A composite outer mold composed of an outer mold 4 , a second outer mold 5 and a third outer mold 6 , as well as a core mold 7 , a die 8 and a die platen 9 .

[0025] The composite die is used to be connected with the main extruder, and the composite die is provided with a main flow channel 10 for communicating with the main extruder; wherein the first die 1 is provided with a main material channel 10 for communicating with the main extruder. The main feed port 11, the third die head 3 is provided with an internal thread hole 31 for the screw connection of the mandrel; the resin from the main extruder enters the main material flow channel through the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com