Carbon fiber tool heating cage for vacuum thermal test

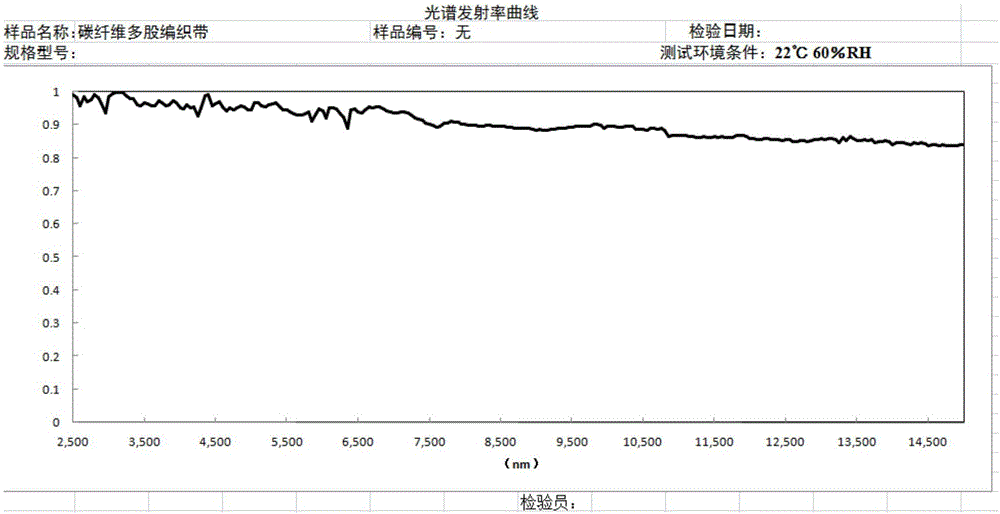

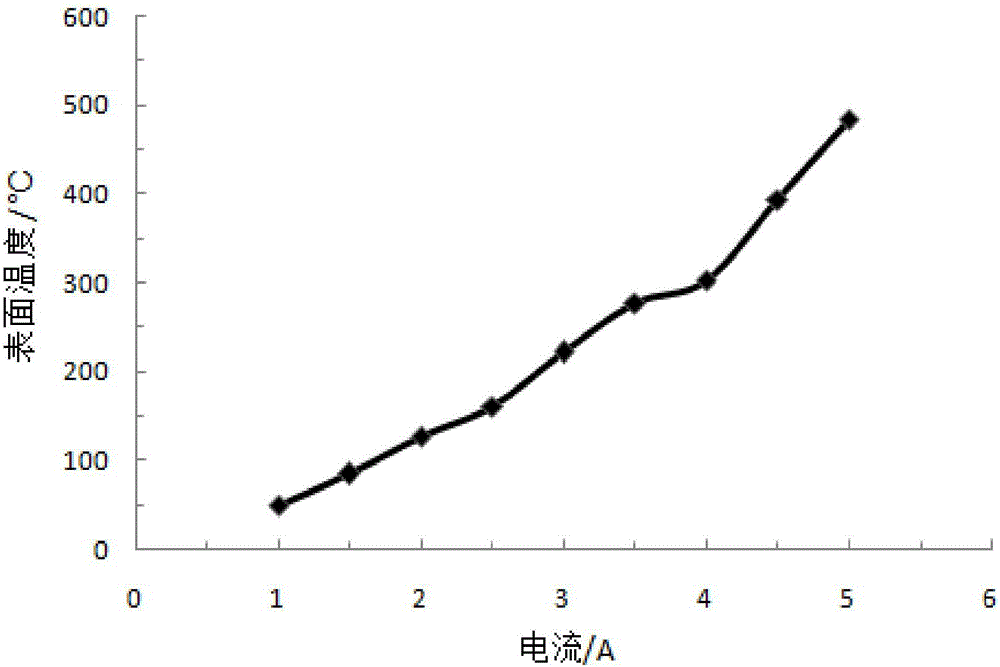

A vacuum thermal test and heating cage technology, applied in the direction of electric heating devices, ohmic resistance heating, heating element materials, etc., can solve the problems of low efficiency and heavy manual workload, and achieve high electrothermal infrared radiation efficiency and material cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following is a specific implementation manner of the content of the present invention, and the content of the present invention will be further clarified through the specific implementation mode below. Of course, the following specific embodiments are described only to illustrate different aspects of the present invention, and should not be construed as limiting the scope of the present invention.

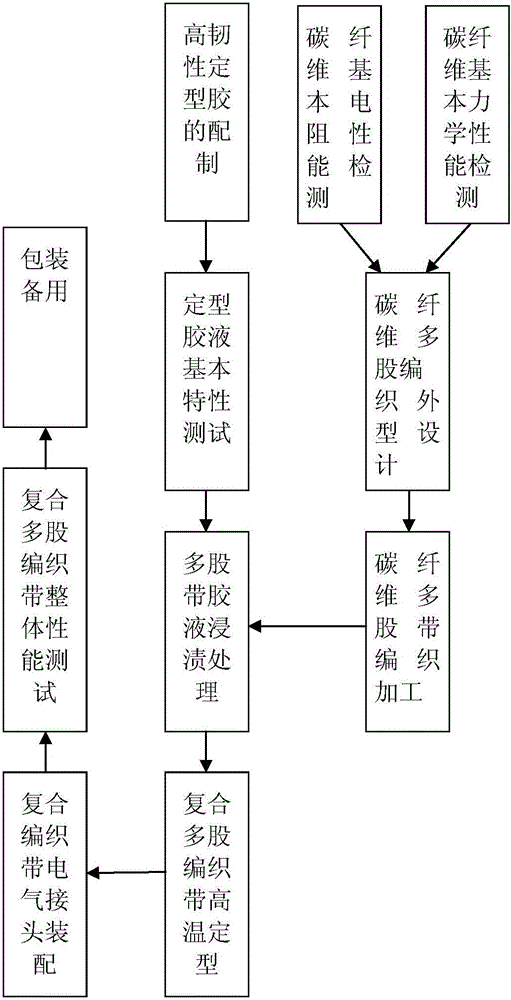

[0033] The design process of carbon fiber heating band among the present invention is as follows:

[0034] 1. The appearance design of the carbon fiber heating belt

[0035] The monofilament diameter of carbon fiber is 5-7 micron, and the superfine carbon fiber monofilament in the finished carbon fiber is generally assembled in bundle form, and the present invention has adopted carbon fiber multi-strand tow ribbon weaving technology, and the fiber tow is woven by specific carbon fiber weaving equipment Multi-directional ribbon weaving is carried out, and the monofilamen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com