Sulfuric acid HRS (Heat Recycling System) type high-temperature acid power generation device

A power generation device, high temperature technology, applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., can solve problems such as power consumption and increase production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following, numerous specific details are set forth in order to provide a thorough understanding of the concepts underlying the described embodiments. It will be apparent, however, to one skilled in the art that the described embodiments may be practiced without some or all of these specific details. In other instances, well known processing steps have not been described in detail.

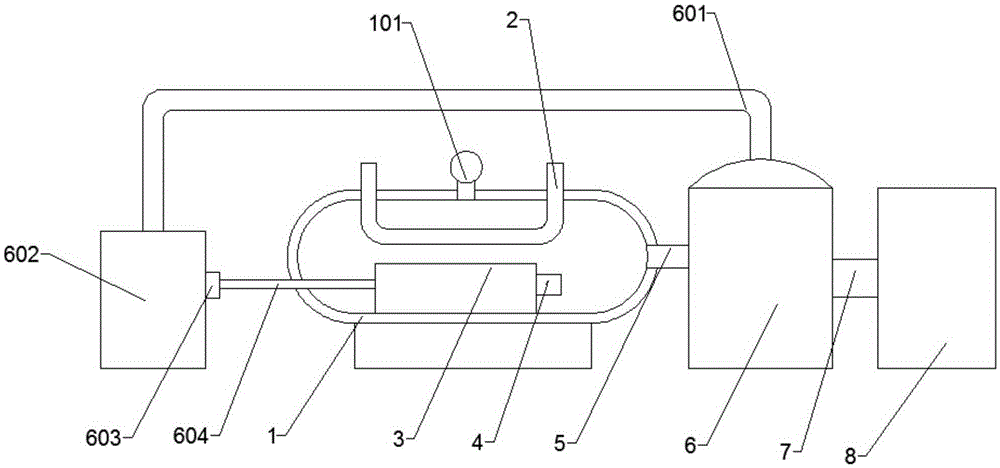

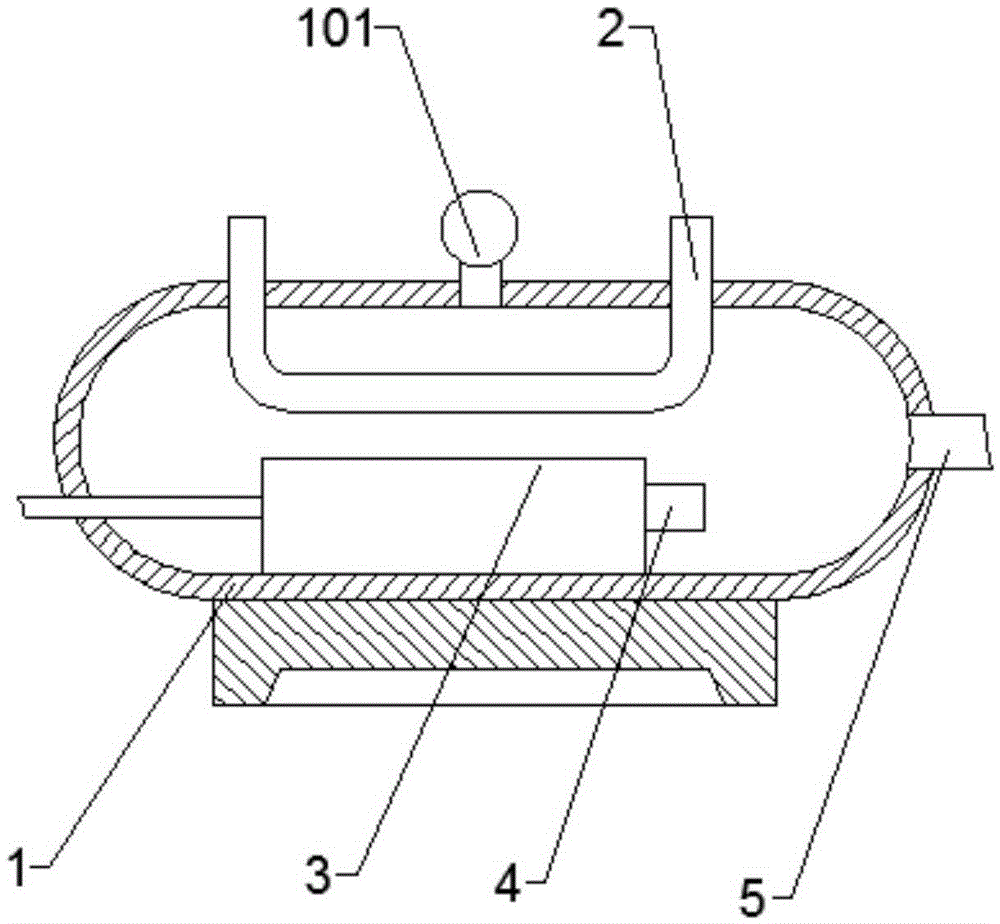

[0021] Such as figure 1 , figure 2 As shown, it includes heat exchanger 1, high temperature sulfuric acid pipe 2, storage tank 3, gas valve 4, gas delivery pipe 5, expander 6, transmission shaft 7, generator 8, pressure gauge 101, return air pipe 601, compressor 602, hydraulic pressure Pump 603, compression tube 604, the heat exchanger 1 is a cylindrical cylinder, the high-temperature sulfuric acid pipe 2 runs through the heat exchanger 1, and the high-temperature sulfuric acid pipe 2 is located at the upper end of the heat exchanger 1, and the high-temperature sulfuric acid pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com