Young pigeon fattening method

A pigeon growth and development technology, applied in the field of breeding, can solve the problems of slow growth, meat drug residues, low breeding economic benefits, etc., and achieve the effects of increasing the rate of release from the cage, improving stability, and improving the effect of irrigation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

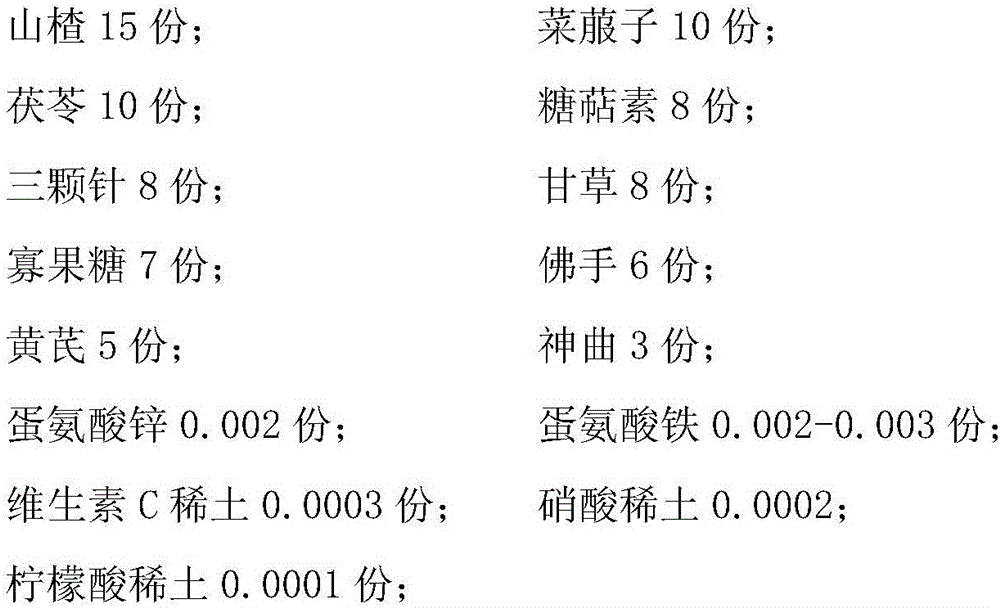

preparation example Construction

[0046] b. Preparation of the feeding material: the fattening feed and distilled water are mixed and stirred at a material-to-liquid ratio of 1:3 until it is fluid, and the feeding material can be obtained;

[0047] c. Feeding method: For 10-20 day-old squabs, use a feeder to feed the squabs, 3 times / day, and 35mL each time; for 20-day-old squabs, Adopt feeder to carry out the feeding of feeding material to pigeon, 3 times / day, and each time 50mL, until the pigeon is slaughtered.

Embodiment 2

[0049] 1. Preparation of fattening feed

[0050] (1) Preparation of the first additive

[0051] a. In parts by weight, take the following ingredients with raw materials:

[0052]

[0053] b. After mixing the weighed raw material components evenly, after low-temperature ultrafine grinding and sieving to 200 meshes, the first additive can be obtained and set aside.

[0054] (2) Preparation of the second additive

[0055] a. In parts by weight, take the following ingredients with raw materials:

[0056] 9 parts of Bacillus subtilis; 8 parts of Bacillus licheniformis;

[0057] 6 parts of Acetobacter; 3 parts of Lactobacillus;

[0058] b. After inoculating the weighed strains in the fermented broth and culturing them, mix the fermented broths evenly, and mix them with the sterilized bran according to the material-to-liquid ratio of 1:1, then dry and pulverize them successively Sieve through 40 meshes to obtain the second additive, which is ready for use.

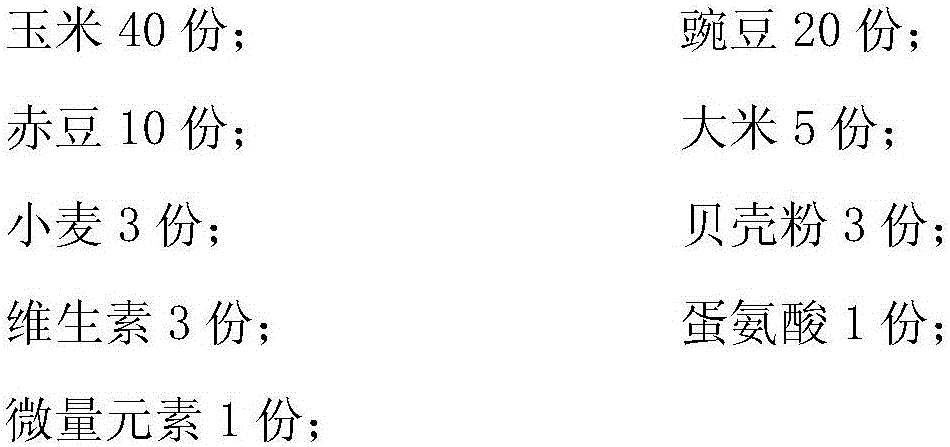

[0059] (3) Prepa...

Embodiment 3

[0069] 1. Preparation of fattening feed

[0070] (1) Preparation of the first additive

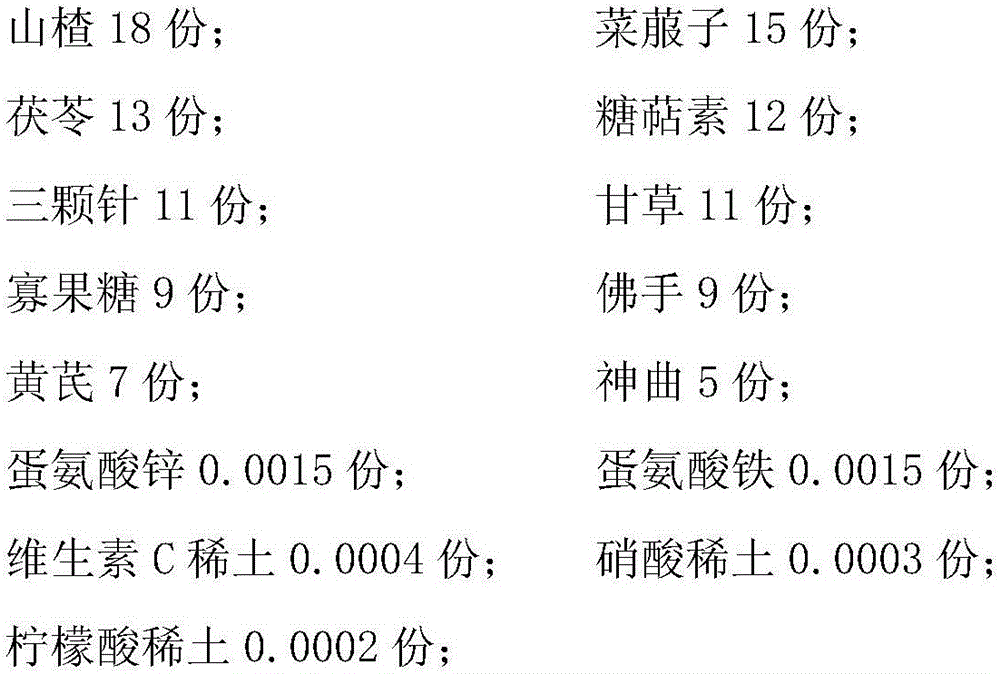

[0071] a. In parts by weight, take the following ingredients with raw materials:

[0072]

[0073] b. After mixing the weighed raw material components evenly, after low-temperature ultrafine grinding and sieving to 200 meshes, the first additive can be obtained and set aside.

[0074] (2) Preparation of the second additive

[0075] a. In parts by weight, take the following ingredients with raw materials:

[0076] 12 parts of Bacillus subtilis; 10 parts of Bacillus licheniformis;

[0077] 8 parts of Acetobacter; 5 parts of Lactobacillus;

[0078] b. After inoculating the weighed strains in the fermented broth and culturing them, mix the fermented broths evenly, and mix them with the sterilized bran according to the material-to-liquid ratio of 1:1, then dry and pulverize them successively Sieve through 40 meshes to obtain the second additive, which is ready for use.

[0079] (3) Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com