Method for preparing high protein content nut beverage

A high-protein, nut technology, applied to other non-alcoholic beverages in the field of food processing, can solve the problems of poor taste, insufficient aroma, low solid content such as protein, etc. The effect of nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

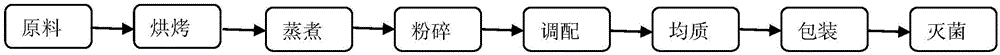

Image

Examples

Embodiment 1

[0036] (1) Raw material preparation of nuts: removing impurities from the nuts;

[0037] (2) Roasting: Macadamia nuts, walnut kernels, and hazelnut kernels are toasted, and different nuts are processed separately, and the processed nuts should have their characteristic aroma;

[0038] (3) Cooking: adding 4 times the weight of deionized water to the nut raw material, and steaming the roasted nuts, the cooking temperature is 100°C, and the cooking time is 15 minutes;

[0039] (4) Pulverization: Add deionized water 16 times the original weight of the nuts to the cooked slurry, and carry out circulation pulverization through a series of high-speed wet grinding equipment, and the circulation treatment time is 30 minutes;

[0040] (5) deployment: add 5% white granulated sugar and 0.4% compound food additive to the feed liquid after circulating wet crushing to improve the stability and sensory quality of the product;

[0041] (6) Homogenization: the second homogenization method is a...

Embodiment 2

[0045] (1) Raw material preparation of nuts: removing impurities from the nuts;

[0046] (2) Roasting: Carry out roasting treatment to hickory nut kernel, almond kernel, different nuts are processed separately, the nut after processing should have its characteristic fragrance;

[0047] (3) Cooking: adding deionized water 5 times its weight to the nut raw material, and steaming the roasted nuts, the cooking temperature is 95°C, and the cooking time is 20 minutes;

[0048] (4) Pulverization: Add deionized water 15 times the original weight of the nuts to the cooked slurry, and carry out circulation pulverization through a series of high-speed wet grinding equipment, and the circulation treatment time is 35 minutes;

[0049] (5) deployment: add 6% white granulated sugar and 0.6% compound food additive to the feed liquid after circulating wet crushing to improve the stability and sensory quality of the product;

[0050] (6) Homogenization: the second homogenization method is adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com