Process device for collecting and purifying chemical tail gas of storage tank

A technology of chemical tail gas and purification process, which is applied in the direction of gas treatment, steam condensation, chemical instruments and methods, etc. It can solve the problems affecting the safety and stability of on-site operations, affecting the physical and mental health of employees, and the large amount of volatile gas, so as to promote clean production , improve the surrounding environment, low investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

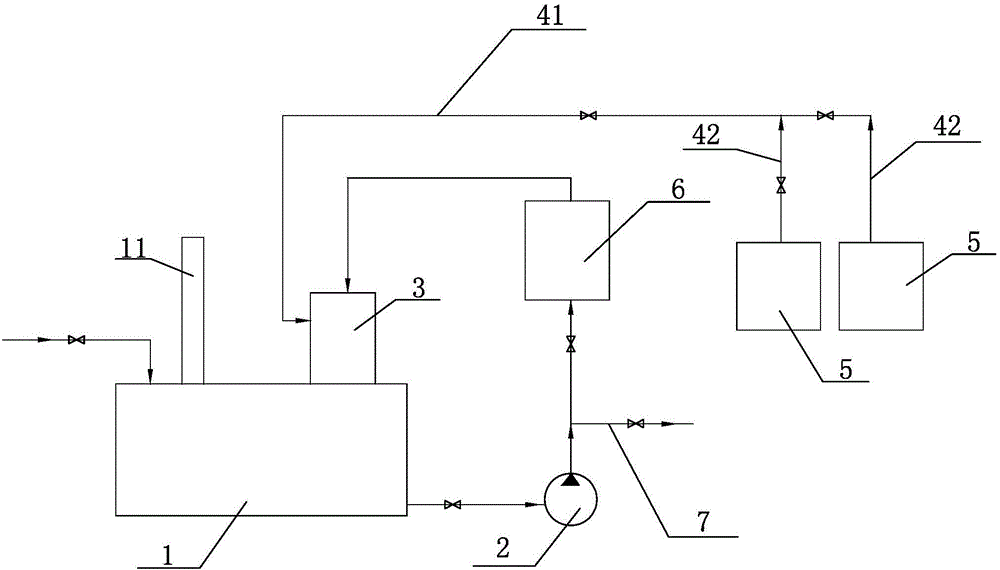

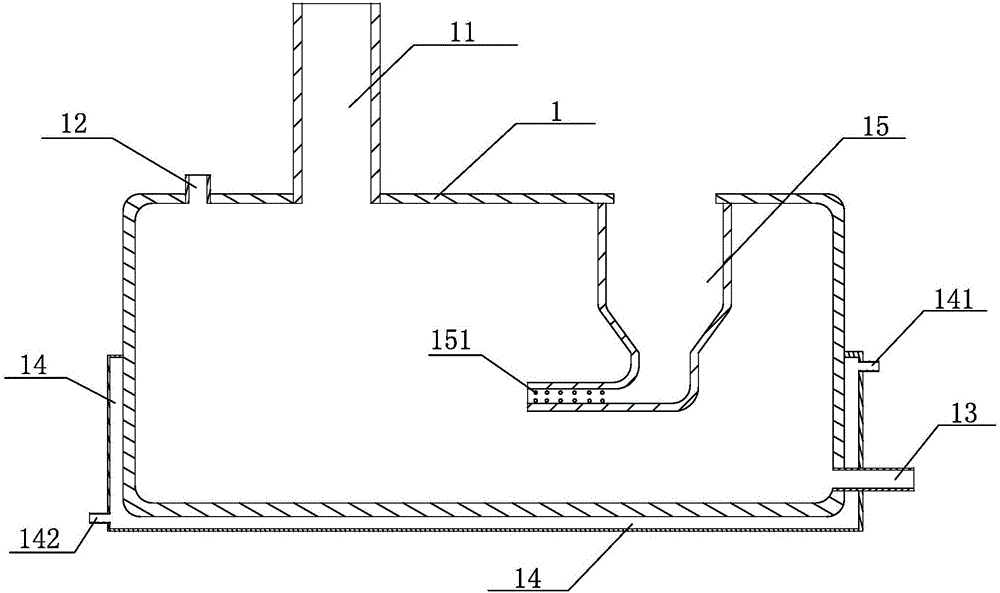

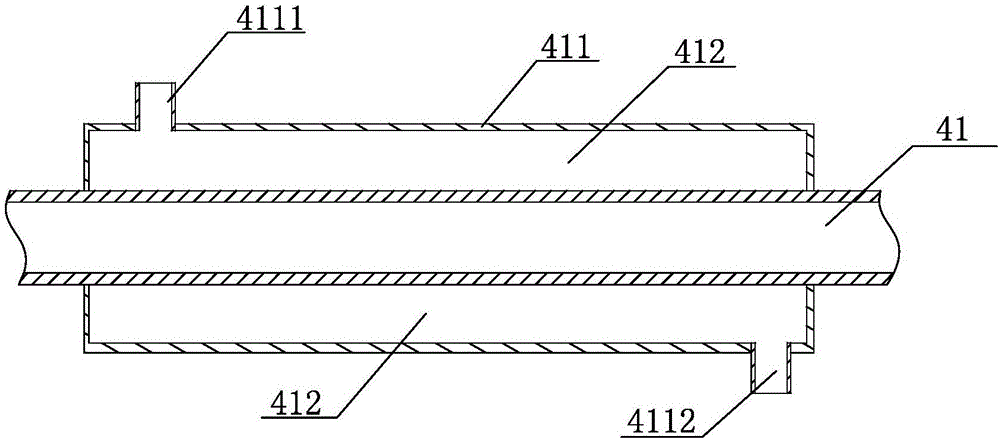

[0022] Below will combine specific embodiment and appended Figure 1-4 , clearly and completely describe the technical solutions in the embodiments of the present invention, obviously, the described embodiments are only some preferred embodiments of the present invention, not all the embodiments. Those skilled in the art can make similar modifications without departing from the connotation of the present invention, so the present invention is not limited by the specific embodiments disclosed below.

[0023] The invention provides a storage tank chemical tail gas collection and purification process device (such as figure 1 Shown), comprise tail gas collection pipeline, gas-liquid mixing device 3, spray liquid storage tank 1 and circulation pump 2, tail gas collection pipeline mainly is to complete the collection work of the chemical tail gas discharged in each storage tank, in this specific embodiment, The exhaust gas collection pipeline includes an exhaust gas confluence pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com