Control device for reducing escaped ammonia in denitration process

A denitration and controller technology, applied in the field of reducing ammonia escape, can solve the problems of unsatisfactory online ammonia escape monitoring of SCR denitration system, lack of reliable detection methods, immature ammonia escape detection, etc. The effect of ensuring the uniformity of matching and reducing the blocking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

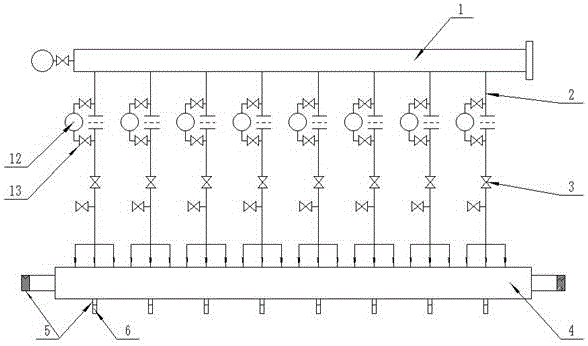

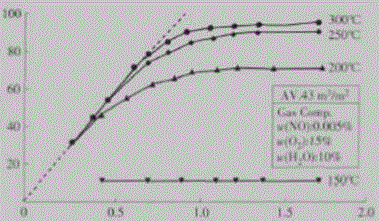

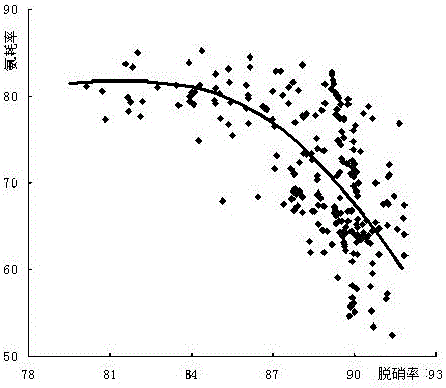

[0028] The present invention will be specifically described below in conjunction with the accompanying drawings, such as Figure 1-7 As shown, a control method for reducing denitrification escaped ammonia, the key points of NOx removal rate are analyzed: (a) The influence of the substance ratio n (NH3 ) / n (NOx ): the substance ratio n(NH3 ) / n ( The effect of NOx ) on denitrification efficiency For example, at 300 ℃, the denitration rate increases with the increase of the material ratio n (NH3 ) / n (NOx ), and the material amount n (NH3 ) / n (NOx ) is less than 0.8 When , its effect is more obvious, almost linearly proportional. See figure 2 (provided by the denitration manufacturer). The results show that: if the input amount of NH3 is too low, the denitrification rate will be limited; if the input amount of NH3 exceeds the required amount, the reaction rate of side reactions such as NH3 oxidation will increase, such as SO2 oxidation to form SO3, and SO3 will react wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com