Silver plating production line iron powder solution online mixed supply mechanism and supply method

A production line and feeding mechanism technology, applied in mixers, chemical instruments and methods, dissolution, etc., can solve the problems of increased production cost, large amount of stirring, waste, etc., to prevent oxidation of iron powder, reduce space occupation, and prevent precipitation The effect produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

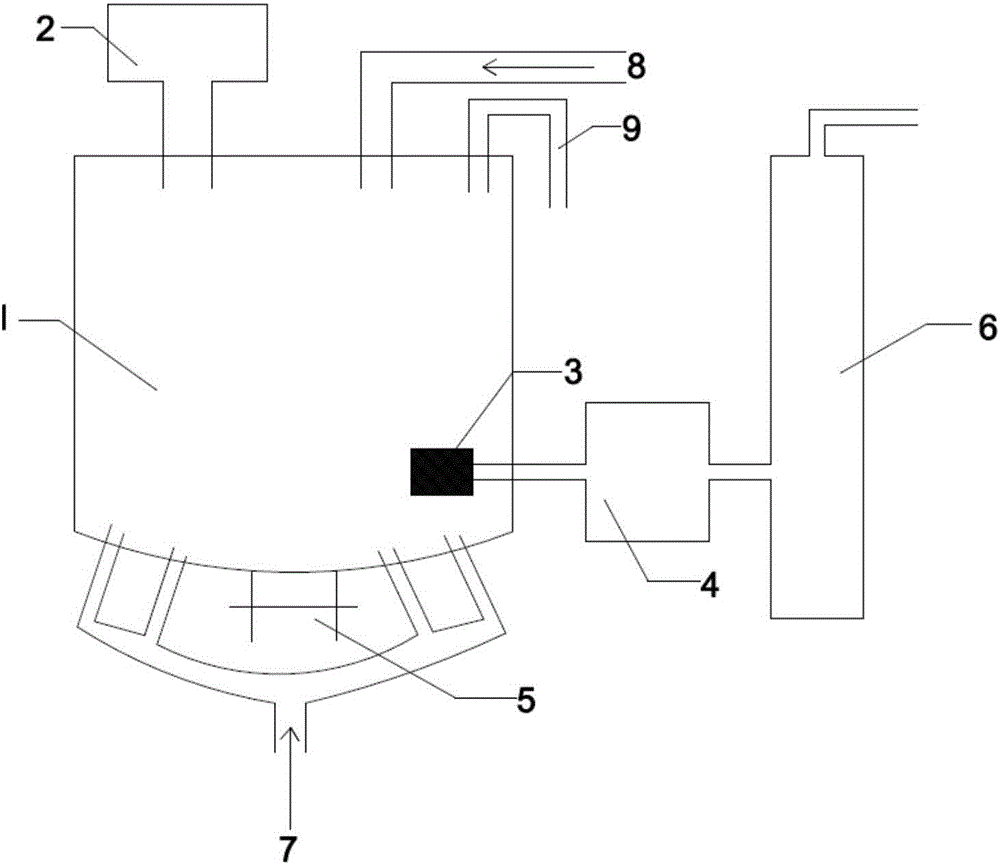

[0024] Such as figure 1 Shown, silver plating production line iron powder solution online mixing supply mechanism of the present invention comprises,

[0025] A closed mixing container 1 is provided with an iron powder feeding mechanism 2 and a pure water pipe 8 on the top of the mixing container, and a plurality of air inlets communicating with an external compressed air source via a pipeline 7 are provided at the bottom of the mixing container. The iron powder feeding mechanism can be a quantitative feeding mechanism such as a screw feeder. The pure water pipe can quantitatively inject pure water into the mixing container, and the top of the mixing container is provided with an esc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com