Expandable graphite production device

A production device, graphite technology, applied in the direction of mixers with rotating stirring devices, transportation and packaging, mixers, etc., can solve the problems of low production efficiency, high operating costs, complex processes, etc., and achieve high production efficiency and low operating costs Low, the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

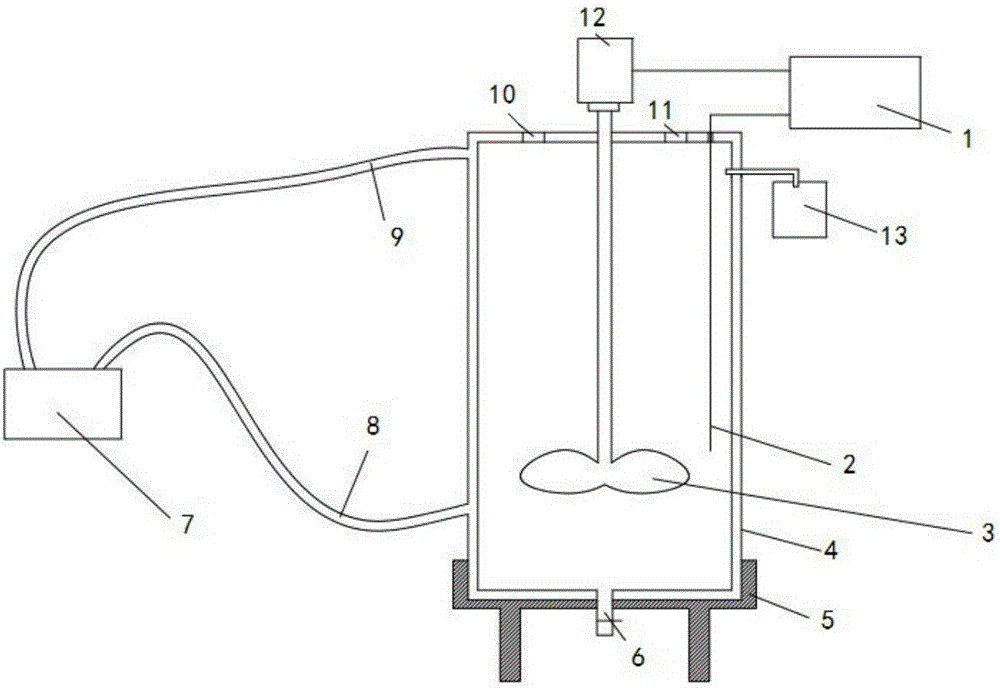

[0029] This embodiment provides an expandable graphite production device, such as figure 1 As shown, it includes a reactor 4, a stirring assembly 3 arranged inside the reactor 4, a gas recovery device 13 and a temperature monitoring assembly 2, and a heating assembly for heating the reaction materials in the reactor 4; the reactor 4 further includes a set The feed assembly on the upper part of the kettle body and the discharge assembly 6 arranged on the lower part of the kettle body.

[0030] Reactor 4 is a double-layer container. As an embodiment of the present invention, in this embodiment, it is more preferably a double-layer transparent colorless glass container. , high borosilicate glass can resist acid and corrosion, moreover, transparent and colorless can effectively monitor the reaction process.

[0031] As an embodiment of the present invention, in this embodiment, the temperature monitoring component 2 is a thermocouple placed inside the reactor 4, which effectively...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap