Micro precision machine tool capable of finishing machining free curved surface at time

A curved surface processing and precision machine tool technology, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems that do not meet the processing function requirements of micro and small parts, the processing accuracy of parts decreases, and the direction of force on the machine tool changes. Achieve the effects of reducing influence/restriction factors, eliminating disturbance, and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings.

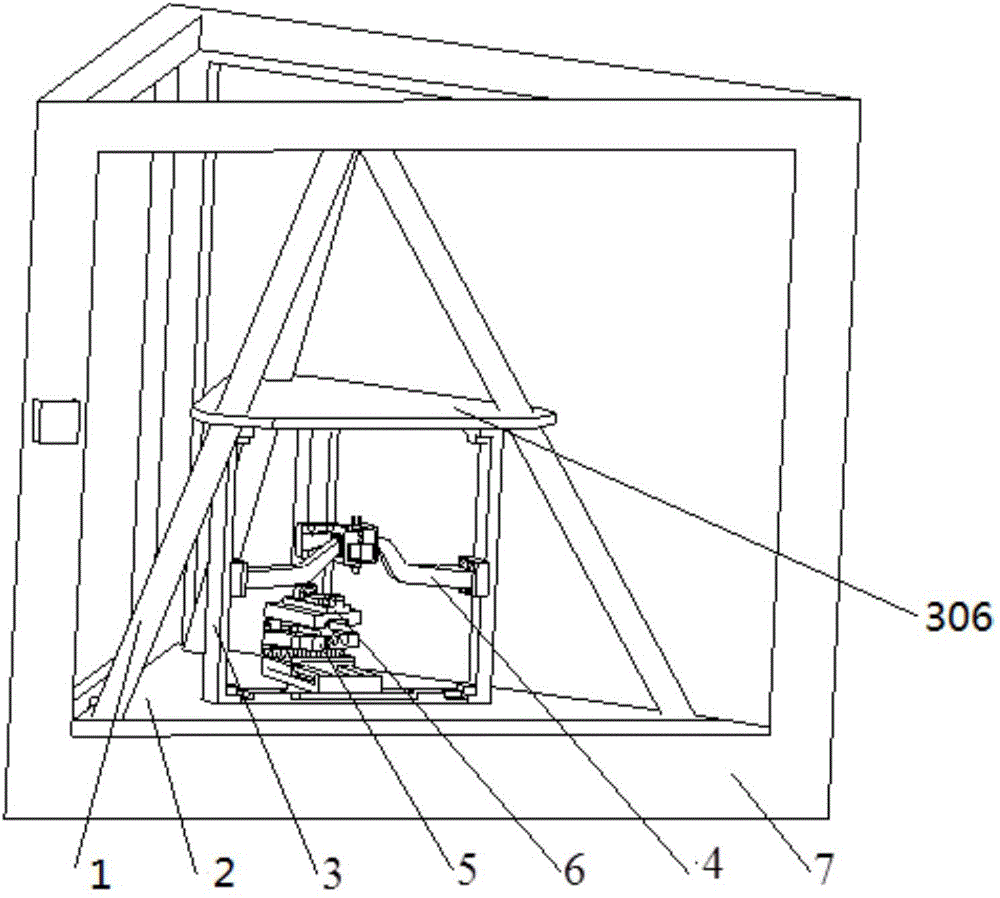

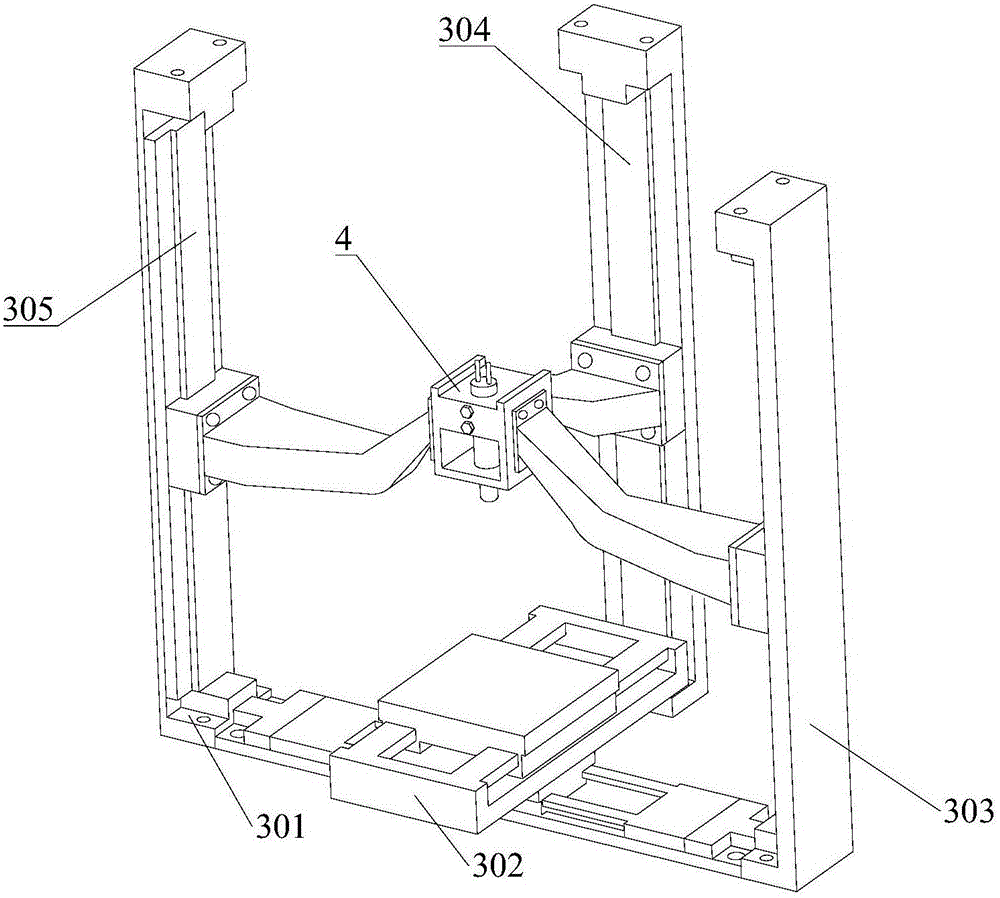

[0048] Such as figure 1 As shown, a micro-precision machine tool of the present invention that can complete free-form surface processing at one time is characterized in that it includes a frame 1, a vibration-damping base 2, a drive assembly 3, a cutter head assembly 4, a workbench 5, and a clamp 6;

[0049] Such as Figure 2 to Figure 3 As shown, the frame 1 is a frame structure, which is in the shape of a regular triangular pyramid as a whole, including a bottom plate and three pillars, the bottom plate is an equilateral triangle, and the lengths of the three pillars are equal. Fixed connection, the other ends of the three pillars are welded together to become the apex of the above-mentioned regular triangular pyramid;

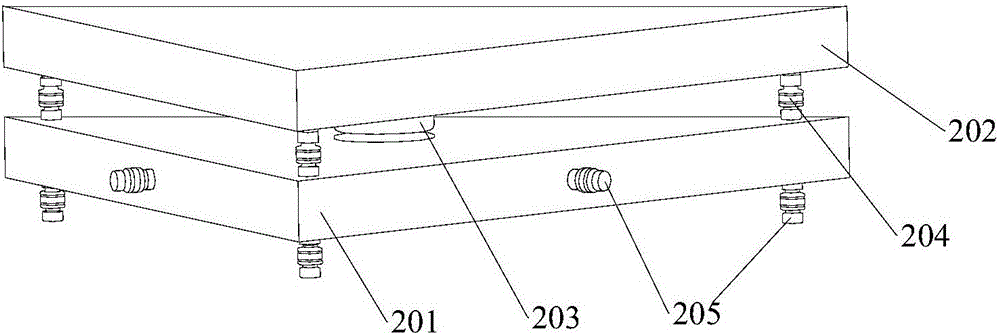

[0050] The above-mentioned frame 1 is placed on the above-mentioned vibration-damping base 2; the above-mentioned cutter head assembly 4 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com