Embedded brushless motor direct-drive cutting machine

A brushless motor and cutting machine technology, applied in the direction of DC motor speed/torque control, electromechanical devices, electrical components, etc., can solve the problems of high noise, slipping affecting speed, low motor efficiency, etc., to achieve low noise and prevent burning machine, cutting torque effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

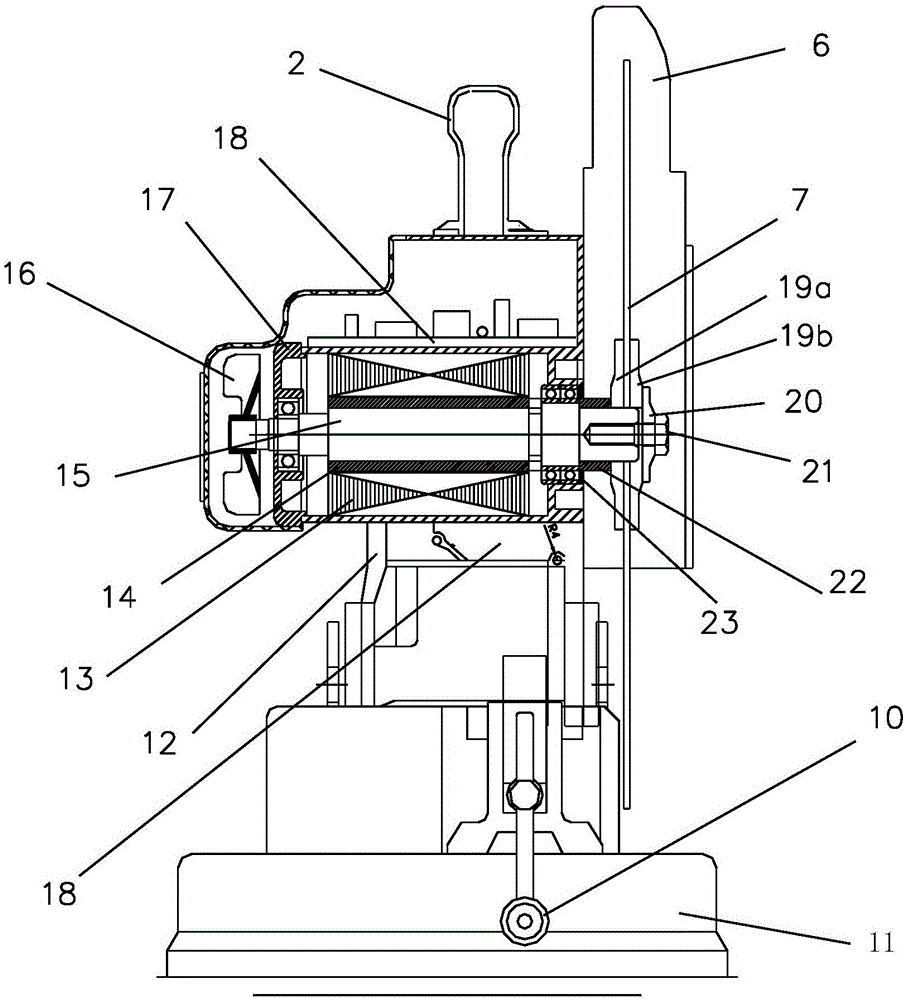

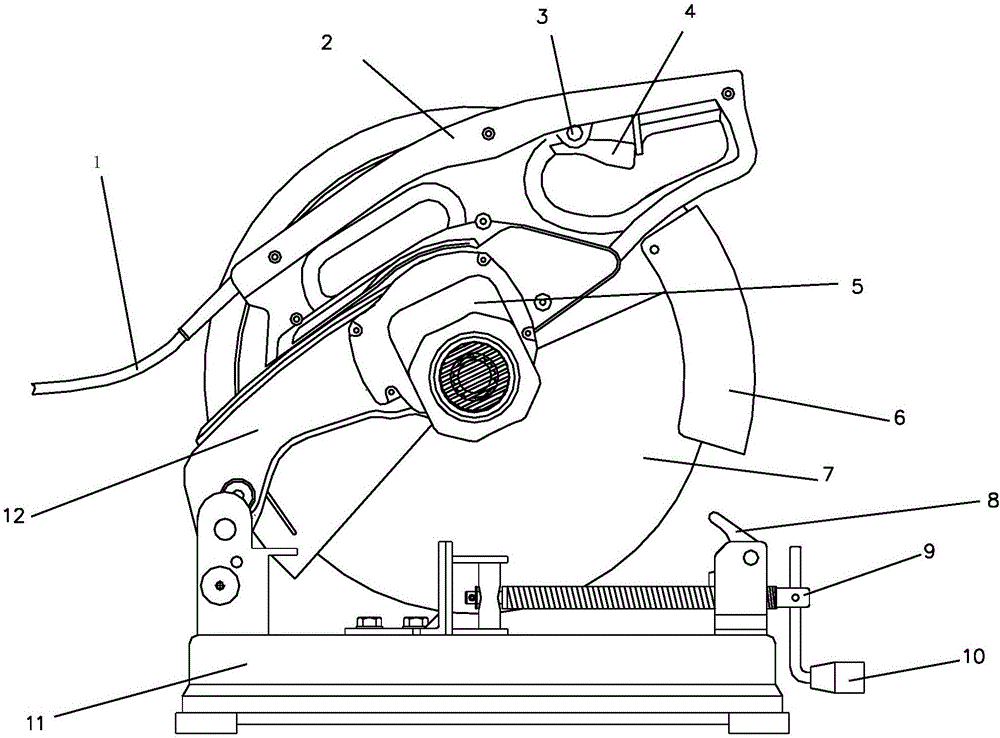

[0017] Combine below figure 1 and figure 2 The present invention is further described in detail with examples.

[0018] Such as figure 1 and figure 2 As shown, the embedded brushless motor direct drive cutting machine includes: a base and a machine head hinged with the base. The machine head has an aluminum alloy casing 12, a handle 2, a protective cover 6, and a grinding wheel sheet 7. Inside the aluminum alloy casing 12 are: a brushless motor embedded in one piece, the brushless motor includes a motor shaft 15, a rare earth strong magnetic sheet 14, a motor stator 13, and a motor end cover 17, and there are two fan blades 16 on the outside of the motor end cover 17 Intelligent electronic circuit board 18 . Intelligent electronic control box cover is arranged on casing 12. The motor shaft 15 fixes the grinding wheel sheet through the pressing plate back ring 22, the inner pressing plate 19a of the emery wheel, the outer pressing plate 19b of the emery wheel, the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com