All-directional moving visual robot system

An omnidirectional mobile robot system technology, applied in the field of omnidirectional mobile vision robot system, can solve the problems of unguaranteed detection accuracy and inability to achieve repeatability, achieve high accuracy, strong independence and unified coordination, intelligent high-efficiency program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

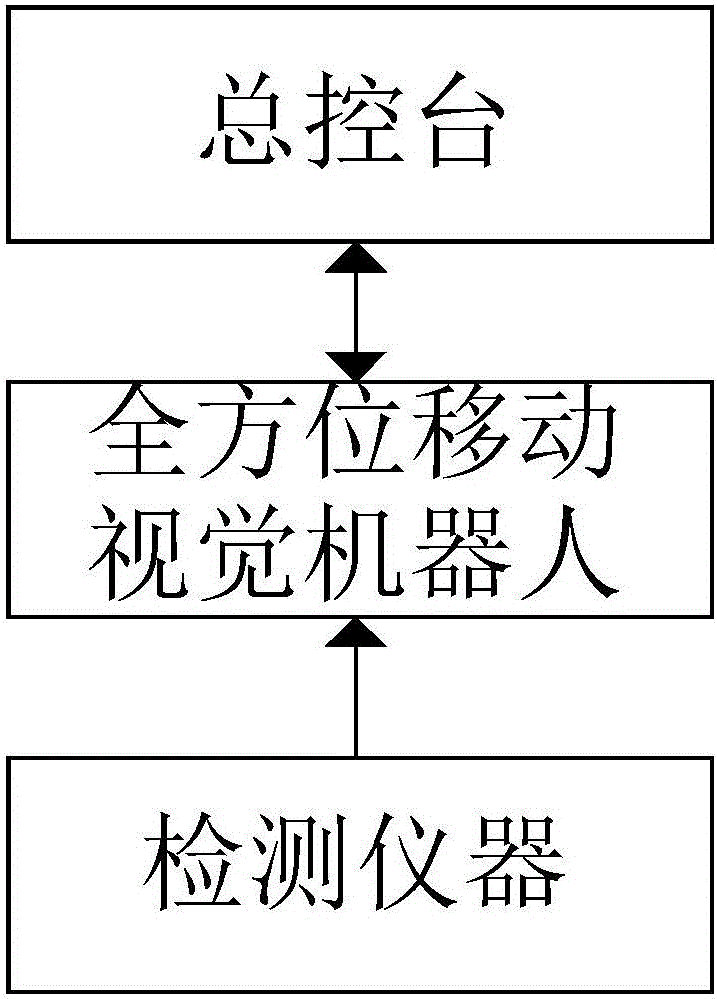

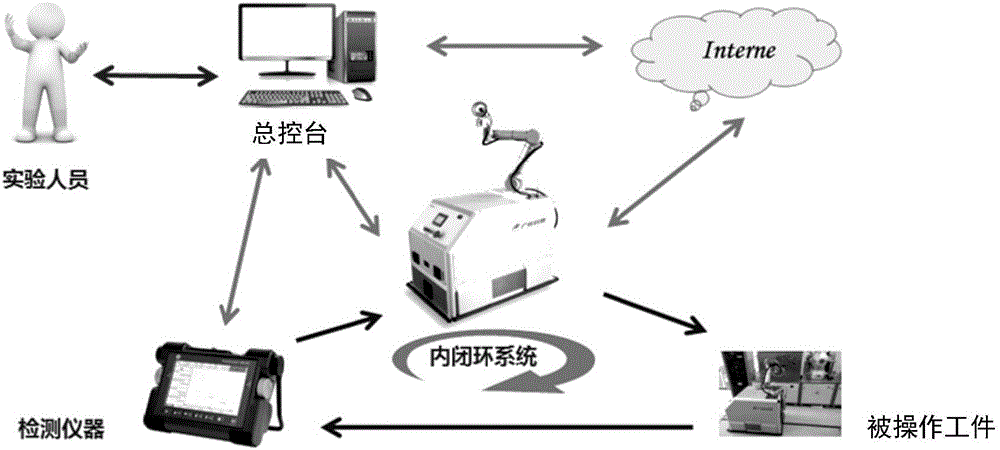

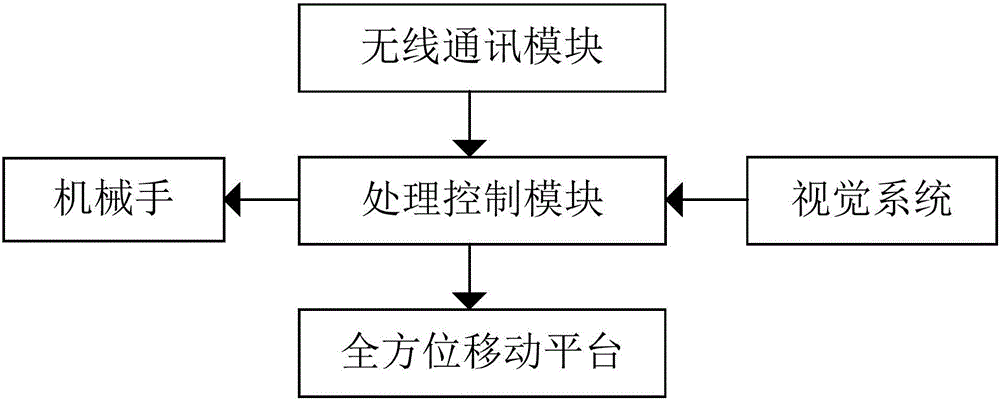

[0031] like figure 1 , figure 2 As shown, the present invention provides an omnidirectional mobile visual robot system, including a master console, which is connected to at least one omnidirectional mobile visual robot, and each omnidirectional mobile visual robot is also connected to a detection instrument;

[0032] The master console is used to manage and command the all-round mobile vision robot to perform corresponding actions and monitor the parameters of each detection instrument in real time; the robot integrates a wireless communication module, and the robot communicates wirelessly with the master console to receive control from the master console For example, the operator wants the robot to stop working, or the operator wants the robot to go to another place for work. The detection instrument sends the working state parameters to the main control console through the robot, realizing the function of the main control console to monitor the parameters of each detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com