Intelligent all-in-one machine for feeding and cutting glass sheets

A technology of smart glass and all-in-one machine, applied in the direction of working accessories, fine working devices, stone processing equipment, etc., can solve the problems of wasting time and labor, increasing the production cost of enterprises, wasting labor and time, etc., to reduce the amount of labor, The effect of improving production efficiency and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

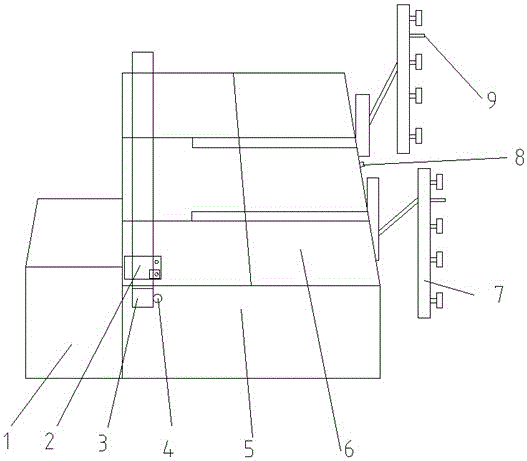

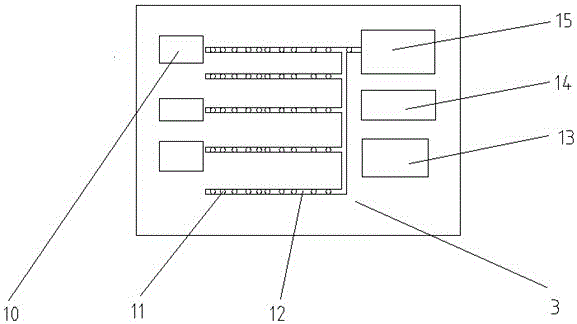

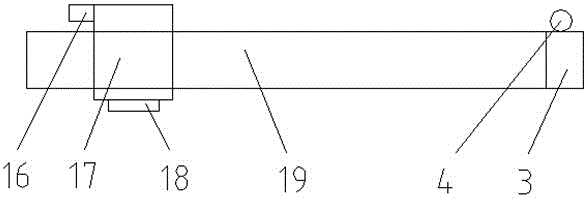

[0022] Figure 1-3 The first embodiment of the present invention is shown: an intelligent glass cutting machine, including a base 5, a drive motor 13, a vacuum pump 14, a fan 15 and a hydraulic cylinder 10, the drive motor 13, a vacuum pump 14, a fan 15 and hydraulic cylinder 10 are all arranged on the base 5, a PLC control box 1 is arranged on one side of the base 5, a cutting table 6 is arranged on the base, a numerical control cutting device 2 is arranged on the cutting table 6, and a CNC cutting device 2 is arranged on the cutting table 6 There is an automatic loading mechanism 7 on the other side of the glass, no need for multiple people to operate and carry the glass, and only one person can complete it alone, saving labor and working time. The CNC cutting device 2 includes a CNC motion beam 19 and a CNC motion cutting head 18 , the CNC motion cutting head 18 and the infrared scanning device 4 driven by the CNC servo motor 3 are arranged on the CNC motion beam 19, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com